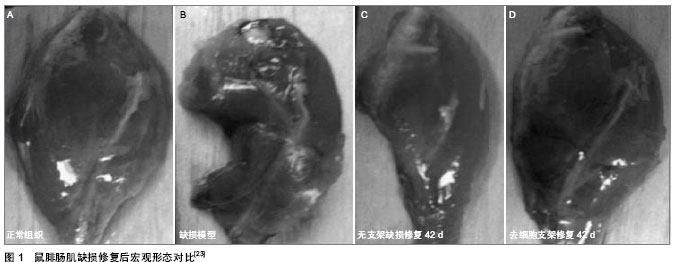

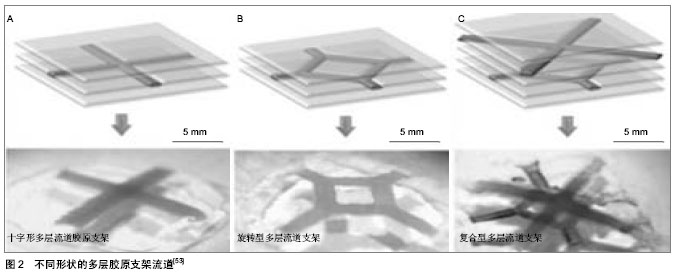

| [1] 90%患者在等待中绝望,器官捐献亟待更多人参与.中国器官捐献网,2012.http://www.organdonation.org.cn/wap.aspx?nid=6059&cp=2&cid=423[2] Salmi M,Paloheimo KS,Tuomi J,et al.Accuracy of medical models made by additive manufacturing (rapid manufacturing).J Craniomaxillofac Surg.2013;41(7):603-609.[3] Wolf MT,Daly KA,Reing JE,Badylak SF. Biologic scaffold composed of skeletal muscle extracellular matrix. Biomaterials. 2012;33:2916-2925.[4] Cleary MA,Geiger E, Grady C,et al. Vascular tissue engineering: the next generation. Trends Mol Med.2012;18: 394-404.[5] Park SH,Kim MS,Lee D,et al.Hybrid microfabrication of nanofiber-based sheets and rods for tissue engineering applications.J Lab Autom.2013;18(6):494-503.[6] Daggumati P,Kurtulus O,Chapman CA,et al.Microfabrication of Nanoporous Gold Patterns for Cell-material Interaction Studies.J Vis Exp.2013;(77):e50678.[7] Chan V, Zorlutuna P, Jeong JH,et al.Three-dimensional photopatterning of hydrogels using stereolithography for long-term cell encapsulation. Lab hip.2010;10:2062-2070.[8] Melchels FP,Feijen J,Grijpma DW.A review on stereolithography and its applications in biomedical engineering.Biomaterials.2010;31:6121-6130.[9] Arcaute K,Mann B,Wicker R.Stereolithography of spatially controlled multi-material bioactive poly(ethylene glycol) scaffolds.Acta Biomater.2010;6:1047-1054.[10] 朱林重,连芩,靳忠民,等.PEGDA水凝胶的光固化成形工艺研究及其性能评价[J].西安交通大学学,2012,46(12):121-126.[11] Castilho M,Dias M,Gbureck U,et al.Fabrication of computationally designed scaffolds by low temperature 3D printing.Biofabrication.2013;5(3):035012.[12] Chan V,Jeong JH,Bajaj P,et al.Multi-material bio-fabrication of hydrogel cantilevers and actuators with stereolithography.Lab Chip 2012;12:88-98.[13] 《中国组织工程研究与临床康复》杂志社学术部.中国血管组织工程研究[J].中国组织工程研究与临床康复,2011,15(28):5307- 5308.[14] Bolgen N,Yang Y,Korkusuz P,et al.3D ingrowth of bovine articular chondrocytes in biodegradable cryogel scaffolds for cartilage tissue engineering. J Tissue Eng Regen Med.2011;5: 770-779.[15] Khait L,Birla RK.Bypassing the patient: comparison of biocompatible models for the future of vascular tissue engineering. Cell Transplant.2012;21:269-283.[16] Yamamoto Y,Ito A,Fujita H,et al.Functional evaluation of artificial skeletal muscle tissue constructs fabricated by a magnetic force-based tissue engineering technique.Tissue Eng Part A.2011;17:107-114.[17] Chien HW,Tsai WB,Jiang S.Direct cell encapsulation in biodegradable and functionalizable carboxybetaine hydrogels. Biomaterials.2012;33:5706-5712.[18] Kloxin AM,Tibbitt MW,Kasko AM,et al.Tunable hydrogels for external manipulation of cellular microenvironments through controlled photodegradation.Adv Mater.2010;22:61-66.[19] Lin H,Zhang D,Alexander PG,et al.Application of visible light-based projection stereolithography for live cell-scaffold fabrication with designed architecture. Biomaterials.2013; 34(2): 331-339.[20] Campbell EM,Cahill PA, Lally C. Investigation of a small-diameter decellularised artery as a potential scaffold for vascular tissue engineering; biomechanical evaluation and preliminary cell seeding.J Mech Behav Biomed Mater.2012; 14: 130-142.[21] Corona BT,Ward CL,Baker HB,et al.Implantation of in vitro tissue engineered muscle repair (TEMR) constructs and bladder acellular matrices (BAM) partially restore in vivo skeletal muscle function in a rat model of volumetric muscle loss (VML) injury. Tissue Eng Part A.2014:20(3-4):705-715.[22] Mangold S,Schrammel S,Huber G, et al. Evaluation of decellularized human umbilical vein (HUV) for vascular tissue engineering - comparison with endothelium-denuded HUV. J Tissue Eng Regen Med.2012.doi:10.1002/term.1603.[23] Merritt EK,Cannon MV,Hammers DW, et al. Repair of traumatic skeletal muscle injury with bone-marrow-derived mesenchymal stem cells seeded on extracellular matrix. Tissue Eng Part A.2010;16:2871-2881. [24] Bosetti M,Boccafoschi F,Leigheb M,et al.Chondrogenic induction of human mesenchymal stem cells using combined growth factors for cartilage tissue engineering. J Tissue Eng Regen Med.2012;6:205-213.[25] Bourget JM,Gauvin R,Larouche D,et al.Human fibroblast-derived ECM as a scaffold for vascular tissue engineering.Biomaterials.2012;33:9205-9213.[26] 刘志强.基于壳聚糖水凝胶的可注射性心肌组织工程研究[D].中国人民解放军军事医学科学院,2012.[27] 康凯,曲辉,汤继权,等.共价结合生长因子的胶原补片改善大鼠室壁瘤修补术后移植细胞生存率的实验研究[J].中国胸心血管外科临床杂志,2013,20(4):451-456.[28] Chung S,Ingle NP,Montero GA,et al.Bioresorbable elastomeric vascular tissue engineering scaffolds via melt spinning and electrospinning.Acta Biomater. 2010;6(6): 1958-1967.[29] Han J,Lazarovici P,Pomerantz C,et al.Co-electrospun blends of PLGA, gelatin, and elastin as potential nonthrombogenic scaffolds for vascular tissue engineering. Biomacromolecules. 2011;12:399-408.[30] McKeon-Fischer KD,Flagg DH,Freeman JW.Coaxial electrospun poly(ε-caprolactone), multiwalled carbon nanotubes, and polyacrylic acid/polyvinyl alcohol scaffold for skeletal muscle tissue engineering.J Biomed Mater Res Part A.2011;99:493-499.[31] Zhou J,Cao C,Ma X,et al.Electrospinning of silk fibroin and collagen for vascular tissue engineering.Int J Biol Macromol. 2010;47:514-519.[32] 朱琳,贺健康,刘亚雄,等.琼脂糖/胶原复合水凝胶的制备及性能研究[J].西安交通大学学报,2013,47(10):121-126.[33] 刘巨超.片状工程化肝组织体外构建及大鼠原位移植的实验研究[D].中国人民解放军医学院,2012.[34] Nikkhah M,Eshak N,Zorlutuna P,et al.Directed endothelial cell morphogenesis in micropatterned gelatin methacrylate hydrogels.Biomaterials.2012;33:9009-99018.[35] Wang PY,Wu TH,Tsai WB,et al.Grooved PLGA films incorporated with RGD/YIGSR peptides for potential application on skeletal muscle tissue engineering. Colloids Surfaces BBiointerfaces.2013;110:88-95.[36] Huang Z,Li X,Martins-Green M,et al.Microfabrication of cylindrical microfluidic channel networks for microvascular research.Biomed Microdevices.2012;14:873-883.[37] DeVolder RJ,Zill AT,Jeong JH,et al.Microfabrication of proangiogenic cell-laden alginate-g-pyrrole hydrogels. Biomaterials.2012;33:7718-7726.[38] Takeuchi A,Nakafutami S,Tani H,et al. Device for co-culture of sympathetic neurons and cardiomyocytes using microfabrication. Lab Chip.2011;11:2268-2275.[39] Chopra K,Mummery PM,Derby B,et al.Gel-cast glass-ceramic tissue scaffolds of controlled architecture produced via stereolithography of moulds.Biofabrication. 2012;4:045002.[40] Lee H,Fang NX. Micro 3D printing using a digital projector and its application in the study of soft materials mechanics. J Vis Exp.2012:e4457.[41] Melchels FP,Bertoldi K,Gabbrielli R,et al.Mathematically defined tissue engineering scaffold architectures prepared by stereolithography.Biomaterials. 2010;31:6909-6916.[42] Romano PE.3D Printing Live Stem Cells; Hobbit in 3D; Super "Retina Displya"; Your Microbiome; Hospitals Takeover; Income Taxes; Bicyclists; Deer Dangers. Binocular vision & strabology quarterly, Simms-Romano's.2013;28:52-64.[43] Chaim IA,Sabino MA,Mendt M,et al.Evaluation of the potential of novel PCL-PPDX biodegradable scaffolds as support materials for cartilage tissue engineering. J Tissue Eng Regen Med.2012;6:272-279.[44] Chang NJ,Jhung YR,Yao CK,et al. Hydrophilic gelatin and hyaluronic acid-treated PLGA scaffolds for cartilage tissue engineering.J Appl Biomater Funct Mater.2013;11:e45-52.[45] Bian W,Li D,Lian Q,et al.Design and fabrication of a novel porous implant with pre-set channels based on ceramic stereolithography for vascular implantation. Biofabrication. 2011;3:034103.[46] 胡金夫,徐铭恩,徐莹,等.基于细胞三维受控组装技术的细胞芯片构建[J].中国生物医学工程学报,2012,31(3):374-81.[47] 颜永年,李生杰,熊卓,等.基于快速原型的组织工程支架成形技术[J].机械工程学报,2010,46(5):93-98.[48] Gill AA, Claeyssens F.3D structuring of biocompatible and biodegradable polymers via stereolithography.Methods Mol Biol.2011;695:309-321.[49] Seck TM,Melchels FP,Feijen J,et al.Designed biodegradable hydrogel structures prepared by stereolithography using poly(ethylene glycol)/poly(D,L-lactide)-based resins. J Control Release.2010;148(1):34-41.[50] 黄健,姜山.3D 打印技术将掀起"第三次工业革命"?[J].新材料产业,2013,15(1):62-67.[51] 王雪莹.3D 打印技术及其产业发展的前景预见[J].创新技术, 2012,11(12):3-5.[52] Mironov V,Kasyanov V,Markwald RR.Organ printing: from bioprinter to organ biofabrication line. Curr Opin Biotechnol. 2011;22:667-673.[53] Lee W,Lee V,Polio S,et al.On-demand three-dimensional freeform fabrication of multi-layered hydrogel scaffold with fluidic channels.Biotechnol Bioeng. 2010;105(6):1178-1186.[54] Miller JS,Stevens KR,Yang MT,et al.Rapid casting of patterned vascular networks for perfusable engineered three-dimensional tissues.Nature Mat.2012;11:768-774.[55] Arakaki K,Kitamura N,Fujiki H,et al.Artificial cartilage made from a novel double-network hydrogel: In vivo effects on the normal cartilage and ex vivo evaluation of the friction property.J Biomed Mater Res Part A.2010;93:1160-1118.[56] Kirschner CM,Anseth KS.Hydrogels in Healthcare: From Static to Dynamic Material Microenvironments.Acta Mater. 2013;61:931-944.[57] Ronken S,Wirz D,Daniels AU,et al.Double-network acrylamide hydrogel compositions adapted to achieve cartilage-like dynamic stiffness.Biomech Model Mechanobiol. 2013;12(2):243-248.[58] Sharma B,Fermanian S,Gibson M,et al.Human cartilage repair with a photoreactive adhesive-hydrogel composite.Sci Transl Med.2013;5(167):167ra6.[59] Sun JY,Zhao X,Illeperuma WR,et al.Highly stretchable and tough hydrogels. Nature. 2012;489:133-136.[60] Chen YM,Dong K,Li ZQ,et al.Double network hydrogel with high mechanical strength:Performance, progress and future perspective.Sci China Tech Sci.2012;55(8):2241-2254. |