[1] BADER A, MACCHIARINI P. Moving towards in situ tracheal regeneration: the bionic tissue engineered transplantation approach. J Cell Mol Med. 2010;14(7):1877-1889.

[2] JOHNSON C, SHESHADRI P, KETCHUM JM, et al. In vitro characterization of design and compressive properties of 3D-biofabricated/decell ularized hybridgrafts for tracheal tissue engineering. J Mech Behav Biomed Mater. 2016;59:572-585.

[3] MURPHY SV, ATALA A. 3D bioprinting of tissues and organs. Nat Biotechnol. 2014;32(8):773.

[4] RUBIKAS R, MATUKAITYTĖ I, JELISIEJEVAS JJ, et al. Surgical treatment of non-malignant laryngotracheal stenosis. Eur Arch Otorhinolaryngol. 2014;271(9):2481-2487.

[5] STEGER V, HAMPEL M, TRICK I, et al. Clinical tracheal replacement: transplantation, bioprostheses and artificial grafts. Expert Rev Med Devices. 2008;5(5):605-612.

[6] MACCHIARINI P, JUNGEBLUTH P, GO T, et al. Clinical transplantation of a tissue-engineered airway. Lancet. 2008;372(9655):2023-2030.

[7] BAIGUERA S, DEL GAUDIO C, JAUS MO, et al. Long-term changes to in vitro preserved bioengineered human trachea and their implications fordecellularized tissues. Biomaterials. 2012;33(14):3662-3672.

[8] JOHNSON C, SHESHADRI P, KETCHUM JM, et al. In vitro characterization of design and compressive properties of 3D-biofabricated/decell ularized hybridgrafts for tracheal tissue engineering.J Mech Behav Biomed Mater. 2016;59:572-585.

[9] LI J, CHEN M, FAN X, et al. Recent advances in bioprinting techniques: approaches, applications and future prospects. J Translat Med. 2016;14(1):271-275.

[10] WURTZ A, HYSI I, KIPNIS E, et al. Recent Advances in Circumferential Tracheal Replacement and Transplantation. Am J Transplant. 2016; 16(4):1334-1335.

[11] ZHOU C, SHI Q, GUO W, et al. Electrospun bio-nanocomposite scaffolds for bone tissue engineering by cellulose nanocrystals reinforcing maleic anhydride grafted PLA. ACS Appl Mater Interfaces. 2013;5(9):3847-3854.

[12] HUAN SQ, CHENG WL, BAI L, et al. Fabrication and characterization of electrospun polystyrene/cellulose nanocrystals nanofibrous films.Polym Eng Sci. 2016;32(3):141-146.

[13] 黄江鸿,熊建义,王大平,等.低温快速成型3D打印磁性纳米复合人工骨的性能测定[J].海南医学,2017,28(4):525-530.

[14] 伦保国,周跃,周军海.Kaneda和AF器械的生物力学强度测试[J].第三军医大学学报,2001,23(1):35.

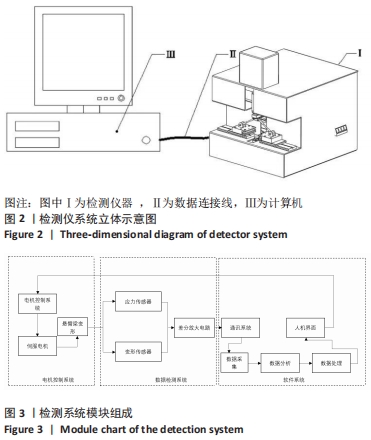

[15] 赵辉,俞朴.微小尺寸弹性零件刚度自动检测方法的研究[J].仪器仪表学报,2001(S1):49-50.

[16] 钱敏,孙宝元,张军.整体式三维压电测力平台的研制[J].大连理工大学学报,2000,40(5):570-572.

[17] 闫迎利.压电效应及其应用[J].安阳师范学院学报,2001(2):44-45.

[18] JIANG Y, ZHOU J, ZHANG Q, et al. Preparation of cellulose nanocrystals from Humulus japonicus stem and the influence of high temperature pretreatment. Carbohydr Polym. 2017;164:284-293.

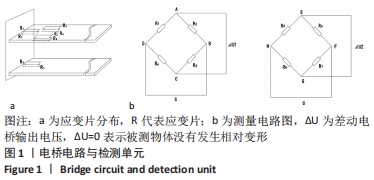

[19] 钱国梁.电阻应变片电桥的一种平衡电路[J].航空测试技术, 1983(3):42-44.

[20] 李杨,解彬彬,王轲,等.电阻应变式机械拉伸实验箱的设计及应用[J].牡丹江师范学院学报(自然科学版),2015(4):28-30.

[21] 姜楠.米饭质构特性测量方法与技术的研究[D].扬州:扬州大学, 2010.

[22] 曹力.微小型材料力学性能测试装置的研究[D].长春:吉林大学, 2008.

[23] 徐文奎,黄海波,李相鹏.微悬臂梁传感器用于测量酵母菌弹性模量[J].微纳电子技术,2016,53(1):25-30.

[24] 杨国太,刘旭,卢荣胜.小尺度试件材料力学性能测试拉伸机系统设计[J].实验力学,2020,35(5):200-209.

[25] 张佳明,王文瑞,聂帅.高温电阻应变片特性参数标定实验研究[J].中国测试,2014,40(5):25-28.

[26] 揣君,王录民,许启铿,等.小麦PFC模型细观参数标定方法的验证与分析[J].中国粉体技术,2017,23(4):43-48.

[27] 张才茂,伍津津,鲁元刚,等.高敏度小张力膜状生物材料力学检测装置改进[J].第三军医大学学报,2010,32(9):904-907.

[28] 薛璐,田磊,耿彦波.销轴传感器测量原理与标定方法研究[J].工程机械,2021,52(3):50-54+8-9.

[29] 王晓鑫,郭永波,高战朋.大尺寸位移测量分析系统标定方法研究[J].工程与试验,2019,59(1):33-35.

|