| [1] 戴尅戎. 金属对金属人工髋关节假体的昔与今[A]. 中华医学会、中华医学会骨科学分会、中国工程院医药卫生学部.中华医学会第十二届骨科学术会议暨第五届COA国际学术大会教程汇编[C].中华医学会、中华医学会骨科学分会、中国工程院医药卫生学部,2010:2.[2] Martin Ihle, Sabine Mai,Werner E.Siebert,等. 陶瓷球头和金属球头配伍聚乙烯臼杯的20年长期对比磨损研究[J].中华关节外科,2010 ,4 (3) :63-65[3] 程倩,王慧妍,田波,等.非球面人工髋关节接触力学[J].医用生物力学, 2012,27(5):534-541. [4] Komistek R, Dennis D, Ochoa J, et al. In vivo comparison of hip separation after metal-on-metal or metal-on-polyethylene total hip arthroplasty. J Bone Jt Surg Am. 2002;84-A (10):1836-1841.[5] Lombardi A, Mallory T, Dennis D, et al. An in vivo determination of total hip arthroplasty pistoning during activity. J Arthroplasty. 2000;15(6):702-709.[6] 程倩,王元培,田波,等.金属对金属髋关节动态边缘接触力学行为[J].医用生物力学,2012,27(2):186-191.[7] 程倩,田波,王元培.等.金属对金属人工髋关节边缘接触效应[J] .医用生物力学,2011,26(6):508-513.[8] Brodner W, Grubl A, Jankovsky R, et al.Cup inclination and serum concentration of cobalt and chromium after metal-on-metal total hip arthroplasty. J Arthroplasty. 2004;19:66-70.[9] O'Dwyer Lancaster-Jones O. The combined effect of head and cup centres mismatch and different cup inclination angles on the occurrence and severity of edge loading and wear in hip replacement. Orthopaedic Research Society. Orlando,USA, 2016.[10] Mak MM, Besong AA, Jin ZM, et al. Effect of microseparation on contact mechanics in ceramic-on-ceramic hip joint replacements. Proc Inst Mech Eng H. 2002;216(6):403-408.[11] Liu F, Williams S, Fisher J. Effect of microseparation on contact mechanics in metal-on-metal hip replacements—A finite element analysis.J Biomed Mater Res Part B. 2015;103(6):1312.[12] Mak M, Jin Z, Fisher J, et al. Influence of acetabular cup rim design on the contact stress during edge loading in ceramic-on-ceramic hip prostheses. J Arthroplasty. 2011;26(1):131-136.[13] Dennis DA, Komistek RD, Northcut EJ, et al. In vivo determination of hip joint separation and the forces generated due to impact loading conditions.J Biomech. 2001;34 (5):623-629.[14] Lombardi AV Jr, Mallory TH, Dennis DA, et al. An in vivo determination of total hip arthroplasty pistoning during activity. J Arthroplasty. 2000; 15 (6):702-709.[15] Nevelos J, Ingham C, Doyle R, et al. Micro-separation of the centers of alumina–alumina artificial hip joints during simulator testing produces clinically relevant wear rates and patterns. J Arthroplasty. 2000;15(6): 793-795.[16] Fisher J. Bioengineering reasons for the failure of metal-on-metal hip prostheses: An engineer’s perspective. J Bone Joint Surg Br. 2011;93: 1001-1004.[17] 周海,季文婷,增祥森,等.髋关节假体脱位与日常行为关系[J]上海交通大学学报,2012, 46(11) :1857-1861.[18] Hua X, Hi J,Wang L,et al.Contact mechanics of modular metal-on-polyethylene total hip replacement under adverse edge loading conditions.J Biomech. 2014;47(13) :3303.[19] Al-Hajjar M, Fisher J, Williams S, et al. Effect of femoral head size on the wear of metal on metal bearings in total hip replacements under adverse edge-loading conditions. J Biomed Mater Res B Appl Biomater. 2013;101(2):213-222.[20] Williams S, Butterfield M, Stewart T, et al. Wear and deformation of ceramic-on-polyethylene total hip replacements with joint laxity and swing phase microseparation. Proc Inst Mech Eng [H]. 2003;217:147-153.[21] Al-Hajjar M, Fisher J, Tipper J, et al. Wear of 36-mm BIOLOX® delta ceramic-on-ceramic bearing in total hip replacements under edge loading conditions. Proc Inst Mech Eng H. 2013;227(5):535-542. [22] Al-Hajjar M, Leslie IJ, Tipper J, et al. Effect of cup inclination angle during microseparation and rim loading on the wear of BIOLOX(R) delta ceramic-on-ceramic total hip replacement. J Biomed Mater Res B Appl Biomater. 2010; 95(2): 263-268.[23] Leslie I, Williams S, Isaac G, et al. High cup angle and microseparation increase the wear of hip surface replacements. Clin Orthop Relat Res. 2009; 467: 2259-2265.[24] Hart AJ, Muirhead-Allwood S, Porter M, et al. Which factors determine the wear rate of large-diameter metal-on-metal hip replacements? J Bone Joint Surg Am. 2013; 95A: 678-685.[25] Stewart T, Tipper J, Insley G, et al. Severe wear and fracture of zirconia heads against alumina inserts in hip simulator studies with micro-separation. J Arthroplasty.2003;18(6): 726-734.[26] Stewart T, Williams S, Tipper J, et al. Advances in simulator testing of orthopaedic joint prostheses. Tribol Res Des Eng Syst. 2003;291-296.[27] Sariali E, Stewart T, Jin Z, et al.Three-dimensional modeling of in vitro hip kinematics under micro-separation regime for ceramic on ceramic total hip prosthesis:An analysis of vibration and noise. J Biomech. 2010;43(2):326-333.[28] Leng J, Al-Hajjar M, Wilcox R, et al. Dynamic virtual simulation of the occurrence and severity of edge loading in hip replacements associated with variation in the rotational and translational surgical position. Proc Inst Mech Eng H. 2017;231(4):299-306.[29] 谢龙汉,蔡明京,苏延全,等.SolidWorks2013三维设计全解视频讲解[M].北京:电子工业出版社,2013:1-167.[30] Al Hajjar M. Wear of hard-on-hard hip prostheses:influence of head size ,surgical position,material and function.Leeds UK,2012.[31] ISO14242-1Implants for surgery-wear of total hip-joint prostheses-Part1:Loading and displacement parameters for wear-testing machines and corresponding environmental conditions for test. ISO 14242-1:2012.[32] 裴未迟,李耀刚,李运红.基于虚拟样机技术-ADAMS的冲击力模型[J].河北理工大学学报,2008,30(4):59-63.[33] 李增刚.ADAMS入门详解与实例[M].北京:国防工业出版社,2014: 126-130.[34] Boer A, Ellenbroek MHM, Hemmes HK, et al.Contact mechanics in MSC Adams - A technical evaluation of the contact models in multibody dynamics software MSC Adams. Twente, 2011. [35] Johnson K. Contact Mechanics. Cambridge University Press, Cambridge, 1985.[36] Sanders AP, Brannon RM. Assessment of the applicability of the Hertzian Contact theory to edge-loaded prosthetic hip bearings. J Biomech. 2011;44(16):2802-2808.[37] Antoine JF, Visa C, Abba G. Approximate analytical model for hertzian elliptical contact problem. Ttibol Int. 2006;128(3):660-664. |

.jpg)

.jpg)

.jpg)

.jpg)

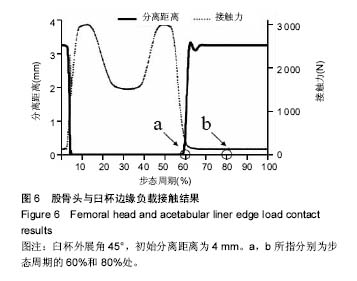

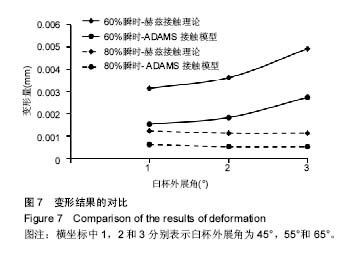

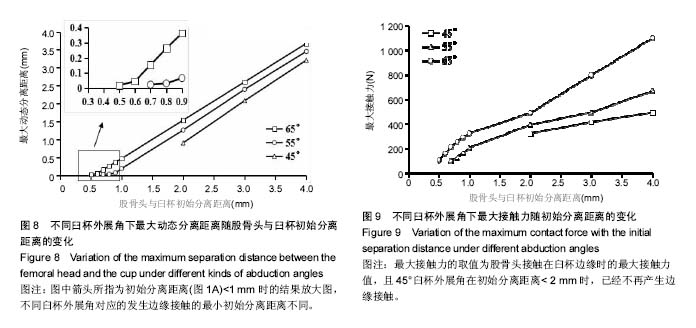

.jpg)