[1] 徐辰,毛远青,朱振安.老年股骨颈骨折治疗进展[J].国际骨科学杂志,2015, 36(2):109-113.

[2] AUGAT P, SCHORLEMMER S. The role of cortical bone and its microstructure in bone strength. Age Ageing. 2006;35(S2):27-31.

[3] 吴淑琴.股骨皮质骨生物力学特性研究[J].中北大学学报,2012,33(2): 216-220.

[4] 许伟,李凡,刘琦.车辆行人碰撞事故中小腿骨折伤害的研究[J].汽车工程, 2011,33(4):321-324.

[5] 周洋洋,倪英杰,李荥娟,等.老年股骨颈骨折治疗研究进展[J].中国修复重建外科杂志,2019,33(8):1033-1040.

[6] 范若寻,刘杰,刘军,等.动态仿真分析车辆低频振动对人体腰椎的损伤机制[J].中国组织工程研究,2018,22(35):5648-5654.

[7] GEISSLER JR, BAJAJ D, FRITTON JC. Cortical bone tissue mechanical quality and biological mechanisms possibly underlying atypical fractures. J Biomech. 2015;48(6):883-894.

[8] RITCHIE RO. How does human bone resist fracture? Skel Bio Med. 2010;1192:72-80.

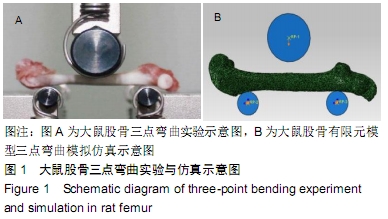

[9] ZHANG GJ, XU SY, YANG J, et al. Combining specimen-specific finite-element models and optimization in cortical-bone material characterization improves prediction accuracy in three-point bending tests. J Biomech. 2018;76:103-111.

[10] THENG PN, KOLOOR, SSR, DJUANSJAH JRP. Assessment of compressive failure process of cortical bone materials using damage-based model. J Mech Behav Biomed. 2017;66:1-11.

[11] HAMBLI R, ALLAOUI S. A robust 3D finite element simulation of human proximal femur progressive fracture under stance load with experimental validation. Ann Biomed Eng. 2013;41(12):2515-2527.

[12] FAN RX, LIU J, JIA ZB, et al. Determination of a tissue-level failure evaluation standard for rat femoral cortical bone utilizing a hybrid computational–experimental method. Proc Inst Mech Eng H. 2018; 232(1):80-89.

[13] TAYLOR M, VERDONSCHOT N, HUISKES R, et al. A combined finite element method and continuum damage mechanics approach to simulate the in vitro fatigue behavior of human cortical bone. J Mater Sci Mater Med. 1999;10:841-846.

[14] 郑利钦,林梓凌,何祥鑫,等.动态载荷下股骨转子间区域皮质骨厚度对骨折类型影响的有限元分析[J].医学研究生学报,2018,31(10):1043-1046.

[15] CHAROENPHAN S, POLCHAI A. Finite element modeling for strain rate dependency of fracture resistance in compact bone. J Biomech Eng. 2007;129:20-25.

[16] MISCHINSKI M, URAL A. Interaction of microstructure and microcrack growth in cortical bone: a finite element study. Comput Methods Biomech Biomed Engin. 2013;16(1):81-94.

[17] BAYRAKTAR HH, MORGAN EF, NIEBUR GL, et al. Comparison of the elastic and yield properties of human femoral trabecular and cortical bone tissue. J Biomech. 2004;37(1):27-35.

[18] HAMBLI R, THURNER PJ. Finite element prediction with experimental validation of damage distribution in single trabeculae during three-point bending tests. J Mech Behav Biomed. 2013;27: 94-106.

[19] IDKAIDEK A, JASIUK I. Cortical bone fracture analysis using XFEM–case study. Int J Numer Meth Biomed Eng. 2016;e02809.

[20] ABDEL-WAHAB AA, SILBERSCHMIDT VV. Experimental and numerical analysis of izod impact test of cortical bone tissue. Eur Phys J. 2012;206(1):41-50.

[21] MACNEIL JA, BOYD SK. Bone strength at the distal radius can be estimated from high-resolution peripheral quantitative computed tomography and the finite element method.Bone.2008;42: 1203-1213.

[22] YANG H, BUTZ KD, DUFFY D, et al. Characterization of cancellous and cortical bone strain in the in vivo mouse tibial loading model using micro CT-based finite element analysis. Bone. 2014;66:131-139.

[23] HOSSEINI HS, DÜNKI A, FABECH J, et al. Fast estimation of Colles’ fracture load of the distal section of the radius by homogenized finite element analysis based on HR-pQCT. Bone. 2017;97:65-75.

[24] BARKAOUI A, BATTAMER A, HAMBLI R. Failure of mineralized collagen microfibrils using finite element simulation coupled to mechanical quasi-brittle damage. Eng Proc. 2011;10:3185-3190.

[25] HAMBLI R, BETTAMER A, ALLAOUI S. Finite element prediction of proximal femur fracture pattern based on orthotropic behavior law coupled to quasi-brittle damage. Med Eng Phys. 2012;34:202-210.

[26] ZHANG R, GONG H, ZHU D, et al. Multilevel femoral morphology and mechanical properties of rats of different ages. Bone. 2015;76:76-87.

[27] KOIVUMCAKI JEM, THEVENOT J, PULKKINEN P, et al. Cortical bone finite element models in the estimation of experimentally measured failure loads in the proximal femur. Bone. 2012;51(4):737-740.

[28] 方娟.不同力学环境导致宏观骨结构变化的数值模拟及多尺度实验研究[D].长春:吉林大学,2016.

[29] HAMBLI R. A quasi-brittle continuum damage finite element model of the human proximal femur based on element deletion. Med Biol Eng Comput. 2013;51:216-231.

[30] HAMBLI R. Micro-CT finite element model and experimental validation of trabecular bone damage and fracture. Bone. 2013;56:363-374.

[31] FAN RX, GONG H, ZHANG R, et al. Quantification of age-related tissue-level failure strains of rat femoral cortical bones using an approach combining macro-compressive test and micro-finite element analysis. J Biomech Eng. 2016;138:041006.

[32] 范若寻,刘杰,甘树坤,等.基于表观压缩实验与有限元分析相结合的骨微观力学性能参数预测方法的研究[J].生物医学工程研究,2018,37(2): 195-199.

[33] CHAPPARD D, BASLE MF, LEGRAND E, et al. New laboratory tools in the assessment of bone quality.Osteoporosis Int.2011; 22(8): 2225-2240.

[34] TASSANI S, PANI M, NOAILLY J, et al. Trabecular fracture zone might not be the higher strain region of the trabecular framework. Front Mater. 2018;5:6.

|