中国组织工程研究 ›› 2014, Vol. 18 ›› Issue (47): 7597-7602.doi: 10.3969/j.issn.2095-4344.2014.47.010

• 组织工程口腔材料 tissue-engineered oral materials • 上一篇 下一篇

颊侧多曲簧弯制前后加热处理对疲劳断裂周期的影响

白雪霏1,王培军1,徐实谦2,侯 录1,刘 玉1

- 1哈尔滨医科大学附属第二医院口腔正畸科,黑龙江省哈尔滨市 150086

2哈尔滨工业大学材料科学与工程学院,黑龙江省哈尔滨市 150001

Heat treatment effect on the fatigue fracture cycle of buccal multiloop

Bai Xue-fei1, Wang Pei-jun1, Xu Shi-qian2, Hou Lu1, Liu Yu1

- 1Department of Orthodontics, the Second Affiliated Hospital of Harbin Medical University, Harbin 150086, Heilongjiang Province, China

2School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, Heilongjiang Province, China

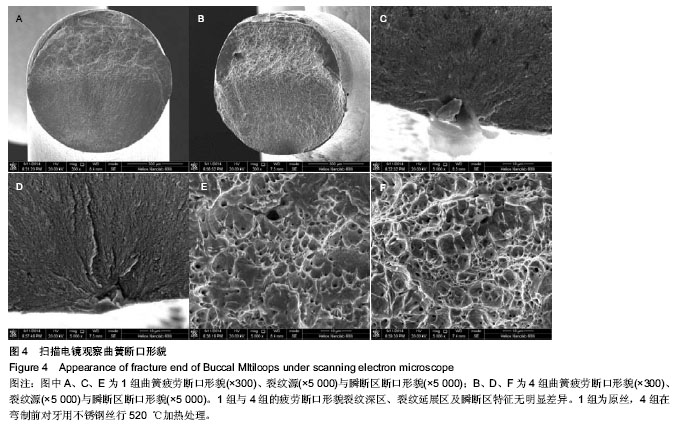

摘要:

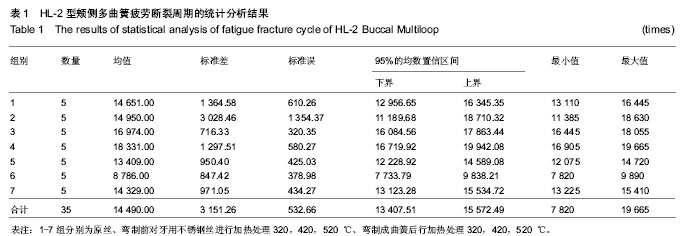

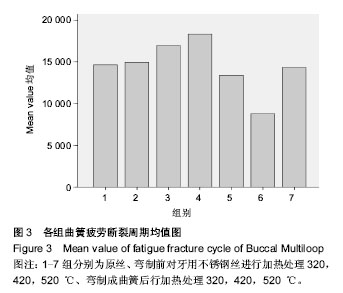

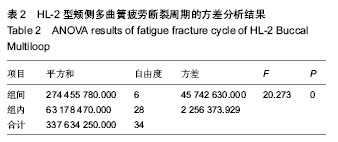

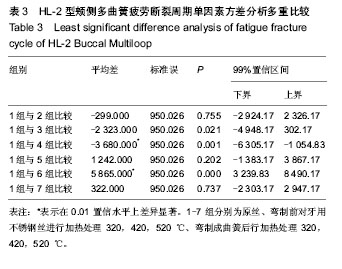

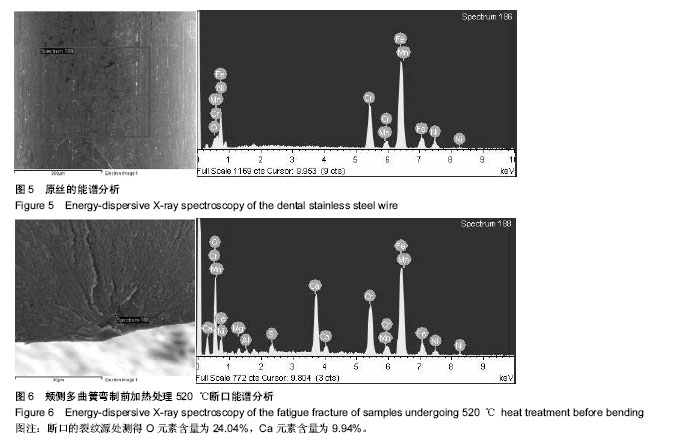

背景:颊侧多曲簧活动矫治器可以阻断性矫治多种青少年错牙合畸形,但在临床中颊侧多曲簧疲劳断裂的问题是不可避免的,如何延长其疲劳断裂周期以确保矫治顺利进行仍然处于研究阶段。 目的:研究颊侧多曲簧弯制前、后进行不同温度加热处理,对其疲劳断裂周期(时间)的影响,从而选出一种能够增强颊侧多曲簧抗疲劳性能的最佳方法。 方法:弯制左侧HL-2型颊侧多曲簧35个,根据曲簧弯制前、后热处理分为7组,5个试样为一组,分别为:原丝组、弯制前对牙用不锈钢丝进行加热处理组(320,420,520 ℃)3组、弯制成曲簧后行加热处理组(320,420,520 ℃)3组,低温热处理后,再用三维开闭口运动模拟测试仪测试其疲劳断裂周期(时间),通过扫描电镜观察断裂曲簧的断口形貌特征。 结果与结论:曲簧疲劳断裂周期均值从大到小排列顺序为:弯制前520 ℃组>弯制前420 ℃组>弯制前320 ℃组>原丝组>弯制后520 ℃组>弯制后320 ℃组>弯制前420 ℃组,说明在曲簧弯制前对牙用不锈钢丝进行加热处理可延长曲簧的疲劳断裂周期,其中520 ℃低温退火工艺可有效提高曲簧抗疲劳断裂的机械性能;在曲簧弯制完成后进行加热处理不能延长曲簧的疲劳断裂周期。扫描电镜下观察弯制前520 ℃组断口裂纹伸展区域有扩大趋势,延缓瞬断过程的形成,组织结构更加均匀。

中图分类号:

.jpg)

.jpg)

.jpg)