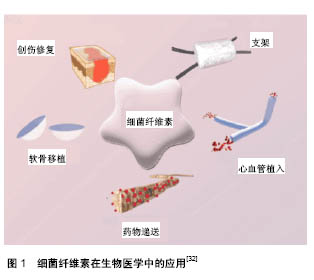

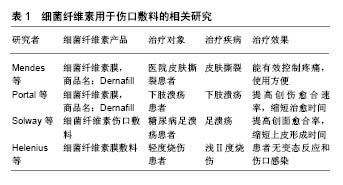

| [1] Zahedmanesh H, Mackle JN, Sellborn A, et al. Bacterial cellulose as a potential vascular graft: Mechanical characterization and constitutive model development. Biomed Mater Res B Appl Biomater. 2011;97(1): 105-113. [2] Malm CJ, Risberg B, Bodin A, et al. Small calibre biosynthetic bacterial cellulose blood vessels: 13-months patency in a sheep model. Scand Cardiovasc J. 2012;46(1):57-62. [3] Fontana JD, Franco VC, de Souza SJ, et al. Nature of plant stimulators in the production of Acetobacter xylinum ("tea fungus") biofilm used in skin therapy. J Appl Biochem Biotechnol. 1991;28-29:341-351. [4] Yano H, Sugiyama J, Nakagaito A, et al. Optically Transparent Composites Reinforced with Networks of Bacterial Nanofibers. Adv Mater. 2005;17:153-155. [5] Brackmann C, Zaborowska M, Sundberg J, et al. In situ imaging of collagen synthesis by osteoprogenitor cells in microporous bacterial cellulose scaffolds. Tissue Eng Part C Methods. 2012;18(3):227-234. [6] Shi Q, Li Y, Sun J, et al. The osteogenesis of bacterial cellulose scaffold loaded with bone morphogenetic protein-2. Biomaterials. 2012;33:6644-6649. [7] Bodin A, Concaro S, Brittberg M, et al. Bacterial cellulose as a potential meniscus implant. J Tissue Eng Regen Med. 2007;1(5): 406-408. [8] Svensson A, Nicklasson E, Harrah T, et al. Bacterial cellulose as a potential scaffold for tissue engineering of cartilage. Biomaterials. 2005;26(4):419-431. [9] Zhu CL, Li F, You QS, et al. Preparation of Nanometer Biomaterial Bacterial Cellulose and Observation of its Ultra-structure. J Biomedical Eng. 2008;27:287-290. [10] Li F, Zhu CL, You QS, et al. In vivo Evaluation of theBiocompatibility of Tissue-engineered Tubular Nanometer Bacterial Cellulose. Chin J Biomed Eng. 2009;28:760-765. [11] Kim SS, Lee SY, Park KJ, et al. Gluconacetobacter sp. gel_SEA623-2, bacterial cellulose producing bacterium isolated from citrus fruit juice. Saudi J Biol Sci. 2017;24(2):314-319. [12] Xie JJ. Preparation and evaluation of antibacterial bacterial cellulose membranes impregnated silver nanoparticles. Shanghai: Donghua University, 2012:199-203. [13] Mohite BV, Patil SV. Physical, structural, mechanical and thermal characterization of bacterial cellulose by G. hansenii NCIM 2529. Carbohydr Polym. 2014;106:132-141. [14] Yao J, Chen S, Chen Y, et al. Macrofibers with High Mechanical Performance Based on Aligned Bacterial Cellulose Nanofibers. ACS Appl Mater Interfaces. 2017;9(24):20330-20339. [15] Lin WC, Lien CC, Yeh HJ, et al. Bacterial cellulose and bacterial cellulose-chitosan membranes for wound dressing applications. Carbohydr Polym. 2013;94(1):603-611. [16] Si H, Luo H, Xiong G, et al. One-step in situ biosynthesis of graphene oxide-bacterial cellulose nanocomposite hydrogels. Macromol Rapid Commun. 2014;35(19):1706-1711[17] Liu W, Gu WY, Zhou XJ, et al. In vitro biocompatibility of bacterial cellulose and Schwann cells. Acad J Sec Mil Med Uni. 2015;36(3): 324-329. [18] Wang ZL, Jia YY, Shi Y, et al. Research on Characterization and Biocompatibility of Nano-bacterial Cellulose Membrane. Chem J Chin Univ. 2009;30(8)1553-1558. [19] Zheng Q, Xi TF, Chen YM, et al. Biocompatibility research of the bacterial cellulose. Chin J Pharm Anal. 2010;7:1389-1392. [20] Lima FM, Pinto FC, Andrade-da-Costa BL, et al. Biocompatible bacterial cellulose membrane in dural defect repair of rat. J Mater Sci Mater Med. 2017;28:37. [21] Qiu J, Liu DL, Zhang Y, et al. Effects of bacterial cellulose on reducing hypertrophic scar in rabbit ears. J Clin Rehabil Tissue Eng Res, 2011;15(25):4597-4601. [22] Sanchavanakit N, Sangrungraungroj W, Kaomongkolgit R, et al. Growth of human keratinocytes and fibroblasts on bacterial cellulose film. Biotechnol Prog. 2006;22(4):1194-1199.[23] Bodin A, Ahrenstedt L, Fink H, et al. Modification of nanocellulose with a xyloglucan-RGD conjugate enhances adhesion and proliferation of endothelial cells:implications for tissue engineering. Biomacromolecules. 2007;8(12):3697-3704. [24] Pandey M, Mohamad N, Low WL, et al. Microwaved bacterial cellulose-based hydrogel microparticles for the healing of partial thickness burn wounds. Drug Deliv Transl Res. 2017;7(1):89-99. [25] Yu J, Huang TR, Lim ZH, et al. Production of Hollow Bacterial Cellulose Microspheres Using Microfluidics to Form an Injectable Porous Scaffold for Wound Healing. Adv Healthc Mater. 2016;5(23): 2983-2992. [26] Solway DR, Consalter M, Levinson DJ. Microbial cellulose wound dressing in the treatment of skin tears in the frail elderly. Wounds. 2010;22(1):17-19. [27] Portal O, Clark WA, Levinson DJ. Microbial cellulose wound dressing in the treatment of nonhealing lower extremity ulcers. Wounds. 2009; 21(1):1-3. [28] Czaja W, Krystynowicz A, Bielecki S, et al. Microbialcellulose-the natural power to heal wounds. Biomaterials. 2006;27:145-151. [29] Fu LN, Zhang Y, Li C, et al. Skin tissuerepair materials from bacterial cellulose by a multilayer fermentation method. J Mater Chem. 2012;22: 12349-12357. [30] Fu L, Zhang J, Yang G. Present status and applications of bacterial cellulose-based materials for skin tissue repair. Carbohydr Polym. 2013;92(2):1432-1442. [31] Gao C, Wan Y, Yang C, et al. Preparation andcharacterization of bacterial cellulose sponge with hierarchical pore structureas tissue engineering scaffold. J Porous Mater. 2011;18:139-145.[32] De Oliveira Barud HG, da Silva RR, da Silva Barud H, et al. A multipurpose natural and renewable polymer in medical applications: Bacterial cellulose.Carbohydr Polym.2016;153:406-420. |

.jpg)

.jpg)