中国组织工程研究 ›› 2019, Vol. 23 ›› Issue (10): 1501-1506.doi: 10.3969/j.issn.2095-4344.1614

• 组织工程口腔材料 tissue-engineered oral materials • 上一篇 下一篇

杜仲胶复合义齿软衬材料制备及吸水性和溶解性检测

罗 恒1,2,高 海1,许雪飞3,冯云枝2

- 1南方医科大学口腔医院口腔修复科,广东省广州市 510280;2中南大学湘雅二医院口腔中心,湖南省长沙市 410012;3广州医科大学附属第二医院药学部,广东省广州市 510220

Preparation, water absorption and solubility of a new Eucommia ulmoides gum composite soft denture liner

Luo Heng1, 2, Gao Hai1, Xu Xuefei3, Feng Yunzhi2

- 1Department of Prosthodontics, Stomatological Hospital, Southern Medical University, Guangzhou 510280, Guangdong Province, China; 2Department of Stomotology, the Second Xiangya Hospital, Central South University, Changsha 410012, Hunan Province, China; 3Department of Pharmacy, the Second Affiliated Hospital of Guangzhou Medical University, Guangzhou 510220, Guangdong Province, China

摘要:

文章快速阅读:

.jpg)

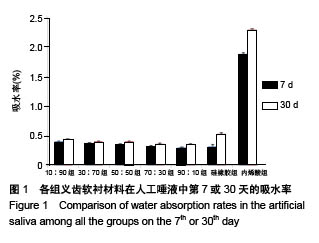

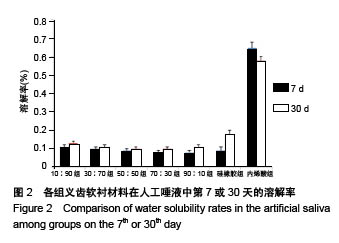

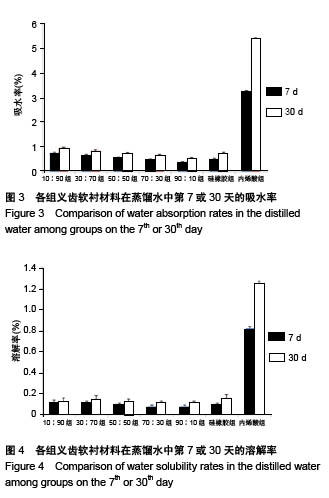

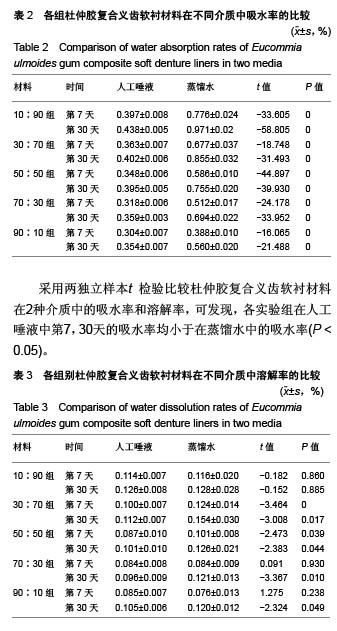

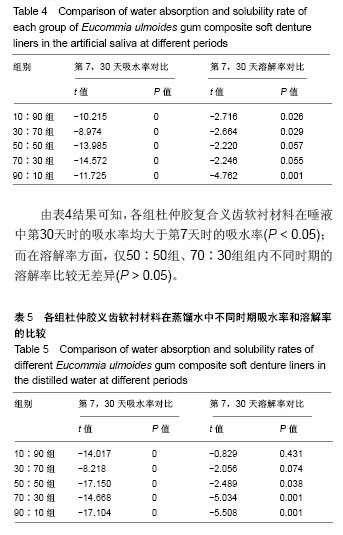

背景:目前在临床上使用最普遍的软衬为硅橡胶类和丙烯酸树脂类,但2种材料均存在一定的不足,因此开发性质稳定、性能优良、兼具抗菌性的软衬材料具有重要临床意义。 目的:制备新型杜仲胶复合义齿软衬材料,同时评价其吸水性和溶解性。 方法:参考现有弹性杜仲胶配方和医用橡胶配方,结合义齿软衬材料的特殊要求,调整杜仲胶与顺丁橡胶的比例(混炼比例分别为10∶90,30∶70,50∶50,70∶30,90∶10),制备新型杜仲胶复合义齿软衬材料,以丙烯酸自凝软衬材料和Silagum硅橡胶义齿软衬材料为对照,将各组样品分别置入人工唾液(或蒸馏水)中7,30 d,检测样品吸水性与溶解性。 结果与结论:①在人工唾液中:第7,30天,各实验组吸水率、溶解率均与硅橡胶组接近,远低于丙烯酸酯组;②在蒸馏水中:第7,30天,各实验组吸水率、溶解率均与硅橡胶组接近,远低于丙烯酸酯组;③在人工唾液或蒸馏水中:丙烯酸酯组浸泡第7,30天的吸水率、溶解率大于其余各组(P < 0.05);④浸泡第7,30天时,同种试件在人工唾液中的吸水率低于在蒸馏水中的吸水率(P < 0.05);浸泡第7天时,仅30∶70组、50∶50组试件在人工唾液中的溶解率低于在蒸馏水中的溶解率(P < 0.05);浸泡第30 天时,30∶70组、 50∶50组、70∶30组、90∶10组试件在人工唾液中的溶解率低于在蒸馏水中的溶解率(P < 0.05);⑤在人工唾液与蒸馏水中:同种试件浸泡第30 天的吸水率均大于第7天的吸水率(P < 0.05);⑥在人工唾液中, 50∶50组浸泡第7,30天的溶解率比较无差异(P > 0.05),70∶30组浸泡第7,30天的溶解率比较无差异(P > 0.05),其他组组内不同时间点的溶解率比较差异显著(P < 0.05);在蒸馏水中,10∶90组浸泡第7,30天的溶解率比较无差异(P > 0.05),30∶70组浸浸泡第7,30天的溶解率比较无差异(P > 0.05),其他组组内不同时间点的溶解率比较差异显著(P < 0.05);⑦结果表明,杜仲胶复合义齿软衬材料的吸水性与Silagum硅橡胶软衬材料接近,显著低于丙烯酸酯软衬材料,且溶解性维持在较低水平。

ORCID: 0000-0002-3399-7148(罗恒)

中图分类号:

.jpg)