中国组织工程研究 ›› 2019, Vol. 23 ›› Issue (32): 5151-5157.doi: 10.3969/j.issn.2095-4344.1399

• 数字化骨科 digital orthopedics • 上一篇 下一篇

金属3D打印个性化股骨假体和4种类型标准化假体的生物力学对比

刘宏伟1,蒋俊锋2,张云坤1,徐南伟1,王彩梅3,张 文4

- 1南京医科大学附属常州第二人民医院骨科,江苏省常州市 213003;2河海大学物联网工程学院,江苏省常州市 213022;3北京爱康宜诚股份有限公司,北京市 102200;4苏州大学骨科研究所,江苏省苏州市 215006

Biomechanical comparison of personalized titanium femoral prosthesis fabricated by three-dimensional printing to four types of cementless prosthesis

Liu Hongwei1, Jiang Junfeng2, Zhang Yunkun1, Xu Nanwei1, Wang Caimei3, Zhang Wen4

- 1Department of Orthopedics, Changzhou Second People’s Hospital, Nanjing Medical University, Changzhou 213003, Jiangsu Province, China; 2College of Internet of Things Engineering, Hehai University, Changzhou 213022, Jiangsu Province, China; 3Beijing AI-Kang Yicheng Limited Company, Beijing 102200, China; 4Orthopedic Institute, Soochow University, Suzhou 215006, Jiangsu Province, China

摘要:

文章快速阅读:

.jpg)

文题释义:

高能电子束熔融金属3D打印:是通过发射高能电子束选择性熔融钛合金粉末,层层堆积完成金属件打印的一种增材制造技术,具有快速、精准、智能、个性化制造的特点。能够打印一体化的金属表面三维微孔结构,其力学强度介于铸造和锻造之间,在个性化精准医疗及植入体界面骨长入有独特的应用价值。

个性化股骨假体:和传统的标准化股骨假体设计和减材制造理念不同,个性化股骨假体是根据具体的股骨髓腔形态量身定做,因此是最符合个体需求的假体,具有磨锉骨量最少、节省手术时间、减少出血量等优势。尤其是金属3D技术的发展为个性化股骨假体的研发提供了更多的技术支持。

摘要

背景:蓬勃发展的金属3D打印增材制造技术为骨科个性化假体的研制带来了全新的机遇,但其生物力学性能是否能满足临床需求尚待深入研究。

目的:探讨高能电子束熔融金属3D打印个性化股骨假体相对于SR组配柄、矩形柄、柱形柄、锥形柄的生物力学优缺点。

方法:分别将3D打印个性化股骨假体、SR组配柄、柱形柄、矩形柄、锥形柄的三维扫描stl格式数据导入UG 8.0建模,修补坏点及空洞。按临床手术要求进行虚拟截骨,置入数字化股骨假体。采用Ansys 10.0软件对5种股骨假体进行有限元网格及节点划分,对假体材料分别赋值。分别模拟双足静止站立、缓慢行走2种状态,对比5种股骨假体在界面应力、初始微动以及应力遮挡率3个方面的差异。

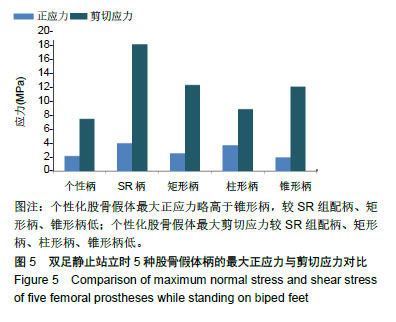

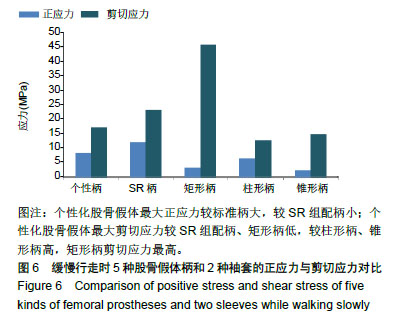

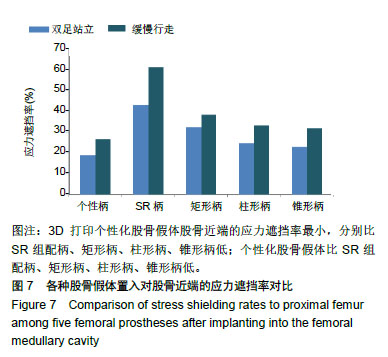

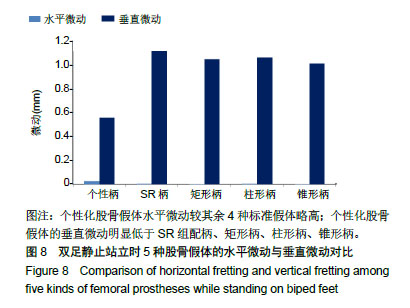

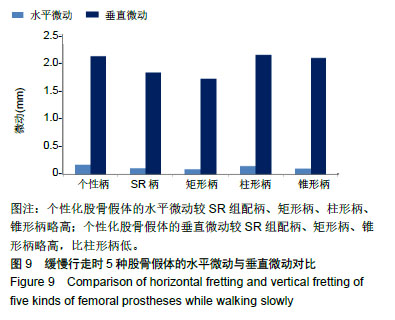

结果与结论:(1)最大应力对比:①双足静止站立:3D打印个性化股骨假体正应力略高于锥形柄(10.83%),较SR组配柄、矩形柄、锥形柄正应力分别低45.65%,15.20%,41.18%;个性化股骨假体剪切应力较SR组配柄、矩形柄、柱形柄、锥形柄分别低58.53%,38.91%,15.64%,37.55%;②缓慢行走:3D打印个性化股骨假体正应力较SR组配柄低,较3种标准柄高;剪切应力较SR组配柄、矩形柄低(25.78%、62.50%),较柱形柄、锥形柄高(35.74%,15.82%);(2)应力遮挡率:①双足静止站立:3D打印个性化股骨假体对股骨近端有着最小的应力遮挡率,比SR组配柄、矩形柄、柱形柄、锥形柄分别低约56.21%,41.88%,23.92%和17.98%;②缓慢行走:个性化股骨假体应力遮挡率比SR组配柄、矩形柄、柱形柄、锥形柄分别低56.84%,31.10%,20.45%,16.69%;(3)假体微动:①双足静止站立:3D打印个性化股骨假体水平微动较其他股骨柄大,最大值26.4 μm,在骨长入的微动范围内,垂直微动均较其余4种柄低;②缓慢行走:3D打印个性化假体的水平微动较其他柄大,最大值172 μm;垂直微动较柱形柄略低(1.45%),较SR组配柄、矩形柄、锥形柄略高(16.10%,23.67%,1.54%);(4)提示高能电子束熔融金属3D打印个性化股骨假体对股骨近端的应力遮挡率低于其他4种类型标准股骨柄,界面应力分布优于SR组配柄,缓慢行走时初始微动略高于其他标准柄,但在骨长入范围内。

ORCID: 0000-0002-0298-3149(刘宏伟)

中图分类号:

.jpg)