[1] CLOWARD RB. The anterior approach for removal of ruptured cervical disks. 1958. J Neurosurg Spine. 2007;6(5):496-511.

[2] SMITH GW, ROBINSON RA. The treatment of certain cervical-spine disorders by anterior removal of the intervertebral disc and interbody fusion. J Bone Joint Surg Am. 1958;40-A(3):607-624.

[3] HEIDECKE V, RAINOV NG, MARX T, et al. Outcome in Cloward anterior fusion for degenerative cervical spinal disease. Acta Neurochir (Wien). 2000;142(3):283-291.

[4] BANWART JC, ASHER MA, HASSANEIN RS. Iliac crest bone graft harvest donor site morbidity. A statistical evaluation. Spine (Phila Pa 1976). 1995;20(9):1055-1060.

[5] Bagby GW. Arthrodesis by the distraction-compression method using a stainless steel implant. Orthopedics. 1988;11(6):931-934.

[6] FARROKHI MR, NIKOO Z, GHOLAMI M, et al. Comparison Between Acrylic Cage and Polyetheretherketone (PEEK) Cage in Single-level Anterior Cervical Discectomy and Fusion: A Randomized Clinical Trial. Clin Spine Surg. 2017;30(1):38-46.

[7] PHAN K, PELLETIER MH, RAO PJ, et al. Integral Fixation Titanium/Polyetheretherketone Cages for Cervical Arthrodesis: Evolution of Cage Design and Early Radiological Outcomes and Fusion Rates. Orthop Surg. 2019;11(1):52-59.

[8] KIM TH, KIM DH, KIM KH, et al. Can the Zero-Profile Implant Be Used for Anterior Cervical Discectomy and Fusion in Traumatic Subaxial Disc Injury? A Preliminary, Retrospective Study. J Korean Neurosurg Soc. 2018;61(5):574-581.

[9] 贾连顺, 魏海峰. 颈椎前路内固定器械的适应证及其进展[J]. 中国脊柱脊髓杂志,2000,10(5):62-64.

[10] MALHAM GM, PARKER RM, BLECHER CM, et al. Assessment and classification of subsidence after lateral interbody fusion using serial computed tomography. J Neurosurg Spine. 2015;23(5):589-597.

[11] PARK JY, CHOI KY, MOON BJ, et al. Subsidence after single-level anterior cervical fusion with a stand-alone cage. J Clin Neurosci. 2016;33:83-88.

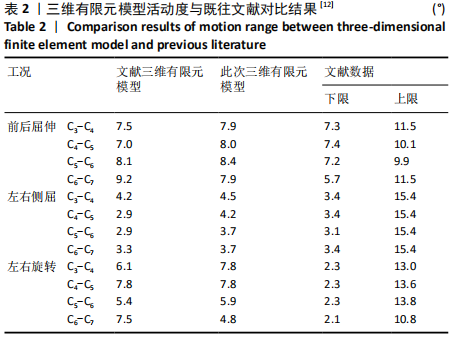

[12] LEE SH, IM YJ, KIM KT, et al. Comparison of cervical spine biomechanics after fixed- and mobile-core artificial disc replacement: a finite element analysis. Spine (Phila Pa 1976). 2011;36(9):700-708.

[13] CHEUNG J, CHEUNG P, LAW K, et al. Postoperative Rigid Cervical Collar Leads to Less Axial Neck Pain in the Early Stage After Open-Door Laminoplasty-A Single-Blinded Randomized Controlled Trial. Neurosurgery. 2019;85(3):325-334.

[14] YANG C, BI Z, YUAN S, et al. [A comparative study of anterior decompression approach by using cervical retractor systems and traditional surgical approach to treat cervical spondylosis]. Zhongguo Xiu Fu Chong Jian Wai Ke Za Zhi. 2008;22(4):394-398.

[15] CHONG E, PELLETIER MH, MOBBS RJ, et al. The design evolution of interbody cages in anterior cervical discectomy and fusion: a systematic review. BMC Musculoskelet Disord. 2015;16:99.

[16] JAIN S, ELTORAI AE, RUTTIMAN R, et al. Advances in Spinal Interbody Cages. Orthop Surg. 2016;8(3):278-284.

[17] IGARASHI H, HOSHINO M, OMORI K, et al. Factors Influencing Interbody Cage Subsidence Following Anterior Cervical Discectomy and Fusion. Clin Spine Surg. 2019;32(7):297-302.

[18] LI Z, XU X, WANG W, et al. Modulation of the mesenchymal stem cell migration capacity via preconditioning with topographic microstructure. Clin Hemorheol Microcirc. 2017;67(3-4):267-278.

[19] DAENTZER D, WILLBOLD E, KALLA K, et al. Bioabsorbable interbody magnesium-polymer cage: degradation kinetics, biomechanical stiffness, and histological findings from an ovine cervical spine fusion model. Spine (Phila Pa 1976). 2014;39(20):E1220-1227.

[20] REN C, SONG Y, XUE Y, et al. Evaluation of Bioabsorbable Multiamino Acid Copolymer/Nanohydroxyapatite/Calcium Sulfate Cage in a Goat Spine Model. World Neurosurg. 2017;103:341-347.

[21] LIPPMAN CR, HAJJAR M, ABSHIRE B, et al. Cervical spine fusion with bioabsorbable cages. Neurosurg Focus. 2004;16(3):E4.

[22] ZHOU C, SONG Y, LIU H, et al. [Current development of research of biodegradable interbody fusion Cage]. Zhongguo Xiu Fu Chong Jian Wai Ke Za Zhi. 2010;24(12):1500-1505.

[23] FROST A, BAGOURI E, BROWN M, et al. Osteolysis following resorbable poly-L-lactide-co-D, L-lactide PLIF cage use: a review of cases. Eur Spine J. 2012;21(3):449-454.

[24] ZHANG L, WANG J, TAO Y, et al. Outcome Evaluation of Zero-Profile Implant Compared with an Anterior Plate and Cage Used in Anterior Cervical Discectomy and Fusion: A Two-Year Follow-Up Study. Turk Neurosurg. 2016;26(3):416-422.

[25] CHEN Y, LIU Y, CHEN H, et al. Comparison of Curvature Between the Zero-P Spacer and Traditional Cage and Plate After 3-Level Anterior Cervical Discectomy and Fusion: Mid-term Results. Clin Spine Surg. 2017;30(8):E1111-E1116.

[26] LI T, YANG JS, WANG XF, et al. Can Zero-Profile Cage Maintain the Cervical Curvature Similar to Plate-Cage Construct for Single-Level Anterior Cervical Diskectomy and Fusion. World Neurosurg. 2020;135: e300-e306.

[27] WANG Z, ZHU R, YANG H, et al. Zero-profile implant (Zero-p) versus plate cage benezech implant (PCB) in the treatment of single-level cervical spondylotic myelopathy. BMC Musculoskelet Disord. 2015;16: 290.

[28] HAKAŁO J, WROŃSKI J, CIUPIK L. Subsidence and its effect on the anterior plate stabilization in the course of cervical spondylodesis. Part I: definition and review of literature. Neurol Neurochir Pol. 2003;37(4): 903-915.

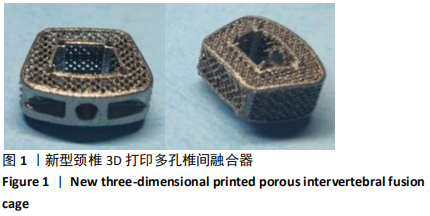

[29] MAYER T, BRÄNDLE G, SCHÖNENBERGER A, et al. Simulation and validation of residual deformations in additive manufacturing of metal parts. Heliyon. 2020;6(5):e03987.

[30] HANC M, FOKTER SK, VOGRIN M, et al. Porous tantalum in spinal surgery: an overview. Eur J Orthop Surg Traumatol. 2016;26(1):1-7. |