| [1]Li L,Zhang D.Dynamic analysis of rotating axially FG tapered beams based on a new rigid-flexible coupled dynamic model using the B-spline method.Compos Struct.2015;124:357-367.[2]Papia E,Jimbo R,Chrcanovic BR,et al.Surface structure and mechanical properties of impaction-modified Y-TZP.Dent Mater.2014;30(8):808-816. [3]Chao SC,Wang MJ,Pai NS,et al.Preparation and characterization of gelatin–hydroxyapatite composite microspheres for hard tissue repair.Mater Sci Eng C Mater Biol Appl.2015;57:113-122.[4]新野正之,平井敏雄,渡边龙三.倾斜机能材料-宇宙机用超耐热材料应用[J].日本复合材料学会志,1987,13(6):257-264.[5]Xuereb M,Camilleri J,Attard NJ.Systematic review of current dental implant coating materials and novel coating techniques.Int J Prosthodont.2015;28(1):51-59.[6]Hanane MA,Khalid EB,Rhali B.Geometrically Non-Linear Free Vibration of Fully Clamped FGM Skew Plates Using Homogenization Technique.Adv Mater Res.2015;1105: 370-380. [7]Bai X,More K,Rouleau CM,et al.functionally graded hydroxyapatite coatings doped with antibacterial components.Acta Biomaterial.2010;6(6):2264-2273.[8]Bykov YV,Egorov SV,Eremeev AG,et al.Temperature profile optimization for microwave sintering of bulk Ni–Al2O3 functionally graded materials.J Mater Proc Technol.2014; 214(2):210-216.[9]Duarte Campos DF,Vogt M,Lindner M,et al.Two-photon laser scanning microscopy as a useful tool for imaging and evaluating macrophage-, IL-4 activated macrophage‐and osteoclast‐based In Vitro degradation of beta-tricalcium phosphate bone substitute material.Microsc Res Tech. 2014;77(2):143-152. [10]Helal WMK,Shi DY.FE Analysis of Functionally Graded Material Plate during Debonding Case with Different Boundary Conditions.Key Eng Mater.2015;627:57-60. [11]Ramu I,Mohanty SC.Buckling Analysis of Rectangular Functionally Graded Material Plates under Uniaxial and Biaxial Compression Load.Procedia Eng.2014;86:748-757. [12]高晓菊,王伯芊,贾平斌,等.功能梯度材料的制备技术及其研发现状[J].材料导报,2014,28(1):31-36.[13]Jin ZH,Paulino GH.Transient thermal stress analysis of an edge crack in a functionally graded material.Int J Fract. 2001;107(1):73-98.[14]Wakashima K,Hirano T,Niino M.Functionally Gradient Materials(Fgm)Architecture: A New Type of Ceramic-Metal Assemblage Designed for Hot Structural Components.Proc. of the ESA Symp. on Space Applications of Advanced Structural Materials (ESA SP-303),ESTEC-ESA,1990.[15]张勇.功能梯度材料制备方法的研究现状[J].热加工工艺, 2012, 41(18):14-16.[16]Pompe W,Worch H,Epple M,et al.Functionally graded materials for biomedical applications.Mater Sci Eng A. 2003;362(1):40-60. [17]Ai Z,Xiang Z,Li Y,et al.Conversion of monkey fibroblasts to transplantable telencephalic neuroepithelial stem cells. Biomaterials.2016;77:53-65. [18]Bahraminasab M,Sahari BB,Edwards KL,et al.Material tailoring of the femoral component in a total knee replacement to reduce the problem of aseptic loosening. Mater Design.2013;52(7):441-451. [19]Sola A,Bellucci D,Cannillo V.Functionally graded materials for orthopedic applications–an update on design and manufacturing.Biotechnol Adv.2016;34(5):504-531.[20]Xu L,Zhang F,Yue X,et al.Advance on Al2O3 Particulates Reinforced Aluminum Metal Matrix Composites (Al-MMCs) Manufactured by the Power Metallurgy (PM) Methods- Improved PM Techniques.MATEC Web of Conferences. 2016;67:06098. [21]Arifin A,Sulong AB,Muhamad N,et al.Material processing of hydroxyapatite and titanium alloy (HA/Ti) composite as implant materials using powder metallurgy: a review.Mater Design.2014;55:165-175. [22]Fuji T,Tohgo K,Araki H,et al.Fabrication and strength evaluation of biocompatible ceramic-metal composite material.J Solid Mech MaterEng.2010;4(11):1699-1699. [23]Koch D,Mauer G,Vaßen R.Manufacturing of Composite Coatings by Atmospheric Plasma Spraying Using Different Feed-Stock Materials as YSZ and MoSi2.J Therm Spray Technol.2017:1-9.[24]Levingstone TJ,Barron N,Ardhaoui M,et al.Application of response surface methodology in the design of functionally graded plasma sprayed hydroxyapatite coatings.Surf Coat Technol.2017;313: 307-318.[25]Pakseresht AH,Javadi AH,Ghasali E,et al.Evaluation of hot corrosion behavior of plasma sprayed thermal barrier coatings with graded intermediate layer and double ceramic top layer.Surf Coat Technol.2016;288:36-45.[26]Baino F,Vitale-Brovarone C.Wollastonite containing bio-ceramic coatings on alumina substrates: Design considerations and mechanical model.Ceram Int. 2015;41(9): 11464-11470.[27]鲍雨梅,徐哲玉,马龙,金志伟.氧化锆增强HA涂层的制备及其磨损性能[J].中国陶瓷,2016,58(4):58-63.[28]Radhika N,Raghu R.Development of functionally graded aluminium composites using centrifugal casting and influence of reinforcements on mechanical and wear properties.Trans Nonferrous Met Soc China. 2016;26(4):905-916. [29]El-Hadad S,Sato H,Watanabe Y.Wear of Al/Al 3 Zr functionally graded materials fabricated by centrifugal solid-particle method. J Mater Proc Technol.2010;210(15):2245-2251.[30]Abdel Hamid Z,El-Etre AY,Fareed M.Performance of Ni-Cu/ZrO2 nano-composite coatings fabricated by electrodeposition technique.Anti-Corrosion Methods Mater. 2017;64(3):315-325.[31]Huang J,Ni Y,Wang Z.Preparation of hydroxyapatite functionally gradient coating on titanium substrate using a combination of electrophoretic deposition and reaction bonding process.Surf Coat Technol.2010;204(21):3387-3392.[32]Salahi E,Esfahani H,Mobasherpour I,et al.Sintering behavior and mechanical properties of alumina/zirconia multilayers composite via nano-powder processing.Ceram Int.2014;40(2): 2717-2722.[33]Salonitis K,D’Alvise L,Schoinochoritis B,et al.Additive manufacturing and post-processing simulation: laser cladding followed by high speed machining.Int J Adv Manuf Technol. 2016;9(85):2401-2411. [34]Li SN,Xiong HP,Li N,et al.Mechanical properties and formation mechanism of Ti/SiC system gradient materials fabricated by in-situ reaction laser cladding.Ceram Int. 2017; 43(1):961-967.[35]Verma G.Functionally Graded Materials.Res J Eng Technol. 2016;7(4):182.[36]Rego BV,Sacks MS.A functionally graded material model for the transmural stress distribution of the aortic valve leaflet.J Biomech.2017;54:88-95.[37]Genga RM,Akdogan G,Polese C,et al.Abrasion wear, thermal shock and impact resistance of WC-cemented carbides produced by PECS and LPS.Int J Refract Metals Hard Mater. 2015;49:133-142. [38]Askari E,Mehrali M,Metselaar IH,et al.Fabrication and mechanical properties of AL2O3/SiC/ZrO2 functionally graded material by electrophoretic deposition.J Mech Behav Biomed Mater. 2012;12:144-150.[39]张波,郭艾.磨损颗粒引发假体周围骨溶解的机制及药物治疗进展[J].中国骨质疏松杂志,2007,13(8):596-599.[40]Radhika N. Mechanical Properties and Abrasive Wear Behaviour of Functionally Graded Al-Si12Cu/Al2O3 Metal Matrix Composite.Trans Indian Ins Metals. 2017;70(1):145-157. [41]Ji X, Xu Z,He L,et al.Effects of Different Inter layers on the Adhesion and Wear Resistance of Diamond-like-carbon Coatings.Vacuum.2013;50(6):1-6.[42]Yang H,Li J,Fang H,et al.Synthesis,characterization and biological activity in vitro of FeCrAl (f)/HA asymmetrical biological functionally gradient materials.J Cent South Univ.2014;21(2):447-453.[43]杜菲菲.反应溅射TiN梯度薄膜及其力学性能研究[D].东北大学,2014.[44]Lin D,Li Q,Li W,et al.Bone remodeling induced by dental implants of functionally graded material.Biomed Mater Res B Appl Biomater.2010;92(2):430-438.[45]Dang Y,Zhang L,Song W,et al.In vivo osseointegration of Ti implants with a strontium-containing nanotubular coating.Int J Nanomedicine.2016;11:1003-1011. [46]Siddiqi A,Kieser JA,De Silva RK,et al.Soft and Hard Tissue Response to Zirconia versus Titanium One‐Piece Implants Placed in Alveolar and Palatal Sites: A Randomized Control Trial.Clin Implant Dent Relat Res.2015;17(3):483-496.[47]Wittneben JG,Buser D,Salvi GE,et al.Complication and Failure Rates with Implant‐Supported Fixed Dental Prostheses and Single Crowns: A 10‐Year Retrospective Study.Clin Implant Dent Relat Res. 2014;16(3):356-364.[48]van Velzen FJ,Ofec R,Schulten EA,et al.10‐year survival rate and the incidence of peri‐implant disease of 374 titanium dental implants with a SLA surface: a prospective cohort study in 177 fully and partially edentulous patients.Clin Oral Implants Res.2015;26(10):1121-1128. [49]Xuereb M,Camilleri J,Attard NJ.Systematic review of current dental implant coating materials and novel coating techniques. Int J Prosthodont.2015;28(1):51-59.[50]Chrcanovic BR,Kisch J,Albrektsson T,et al.Factors influencing early dental implant failures. J Dent Res. 2016;95(9):995-1002.[51]Sadollah A,Bahreininejad A.Optimum gradient material for a functionally graded dental implant using metaheuristic algorithms.J Mech Behav Biomed Mater. 2011;4(7):1384-1395.[52]Hedia HS,Aldousari SM,Abdellatif AK,et al.A new design of cemented stem using functionally graded materials(FGM).Biomed Mater Eng.2014;24(3):1575-1588. [53]Raza MR,Sulong AB,Muhamad N,et al.Effects of binder system and processing parameters on formability of porous Ti/HA composite through powder injection molding.Adv Mater Res.2015;87:386-392.[54]丁元圣.含氟羟基磷灰石涂层(FHA)钛合金正畸微种植体对骨结合界面周围炎症的影响[D].佳木斯大学,2015.[55]周立伟,陈向深,乔永刚,等.纳米羟基磷灰石/聚醚醚酮复合种植体受力的三维有限元分析[J].口腔医学研究, 2016,32(4):391-394.[56]Xu W,Brandt M,Sun S,et al.Additive manufacturing of strong and ductile Ti–6Al–4V by selective laser melting via in situ martensite decomposition.Acta Materialia.2015;85:74-84.[57]Sharma B,Varghese S.Progress in orthopedic biomaterials and drug delivery.Drug Deliv Transl Res.2016;6(2):75-76.[58]Nam J,Do WS,Stinner DJ,et al.The Highest-Impact Combat Orthopedic and Extremity Injury Articles in the Past 70 Years: A Citation Analysis.J Spec Oper Med.2017;17(1):55-66.[59]Lin X,Yang S,Lai K,et al.Orthopedic implant biomaterials with both osteogenic and anti-infection capacities and associated in vivo evaluation methods.Nanomedicine. 2017;13(1):123-142.[60]Raphel J,Holodniy M,Goodman SB,et al.Multifunctional coatings to simultaneously promote osseointegration and prevent infection of orthopaedic implants.Biomaterials. 2016;84:301-314.[61]Tuchinskiy L.Processes for Making Functionally Graded Materials and Products Produced by These Processes: U.S. Patent Application 14/279,707[P]. 2014-5-16.[62]Bolelli G,Bellucci D,Cannillo V,et al.Comparison between suspension plasma sprayed and high velocity suspension flame sprayed bioactive coatings. Surfand Coat Technol. 2015;280:232-249.[63]程瑶,王铭,王星星,等.仿骨成分多元掺杂羟基磷灰石体外成骨性能研究[J].无机材料学报,2016,31(12):1341-1346.[64]张钰.聚醚醚酮仿生人工骨3D打印热力学仿真及实验研究[D].吉林大学,2014. |

.jpg)

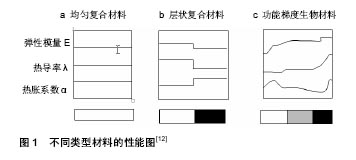

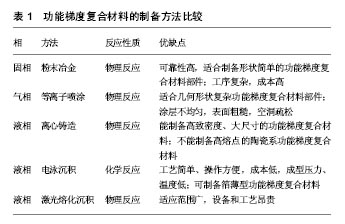

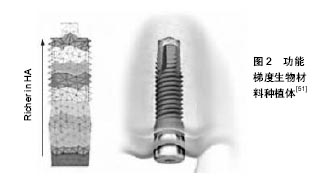

.jpg)