中国组织工程研究 ›› 2021, Vol. 25 ›› Issue (12): 1831-1835.doi: 10.3969/j.issn.2095-4344.3775

• 人工假体 artificial prosthesis • 上一篇 下一篇

单间室膝关节假体衬垫在步态载荷下的磨损性能仿真分析

王献抗,张月静,杨 友,刘 军

- 天津市骨植入物界面功能化与个性化研究企业重点实验室,嘉思特华剑医疗器材(天津)有限公司,天津市 300190

Simulation analysis of wear performance for tibial insert of unicompartmental knee arthroplasty prosthesis under gait load

Wang Xiankang, Zhang Yuejing, Yang You, Liu Jun

- Tianjin Key Laboratory of Functional and Personalized Research on Bone Implant Interfaces, Just Huajian Medical Equipment (Tianjin) Co., Ltd., Tianjin 300190, China

摘要:

文题释义:

文题释义:

单间室膝关节假体:用于对膝关节单侧病变间室进行表面置换,不但手术切口小、术中截骨量少,而且不影响或较少影响其他正常关节间室,不破坏伸膝装置,可保留十字韧带及骨软骨,因此单髁膝关节置换后恢复快、并发症少,保存了膝关节的正常运动和本体感觉。

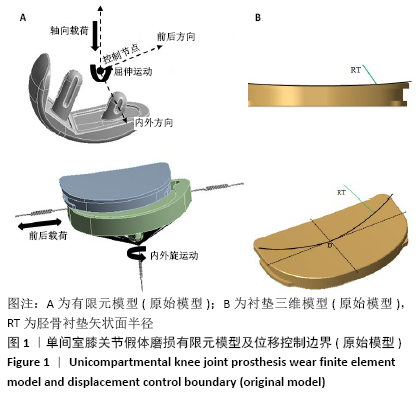

衬垫:目前单间室膝关节假体根据运动方式不同分为活动平台型和固定平台型。该文所述假体为固定平台型单间室假体,包括股骨髁、衬垫与胫骨平台,其中股骨髁通过骨水泥固定于股骨远端,材质为钴铬钼,胫骨平台通过骨水泥固定于胫骨近端,材质为钴铬钼,衬垫通过机械连接固定于胫骨平台,材质为高交联聚乙烯,与股骨髁关节面配合为关节摩擦副。由于股骨髁与衬垫的接触面积较小,造成接触应力较大,临床中易出现磨损问题,造成衬垫失效。

背景:目前,有限元分析多用于全膝关节假体衬垫的磨损仿真研究。

目的:利用有限元分析单间室膝关节假体衬垫形状优化对磨损性能的影响。

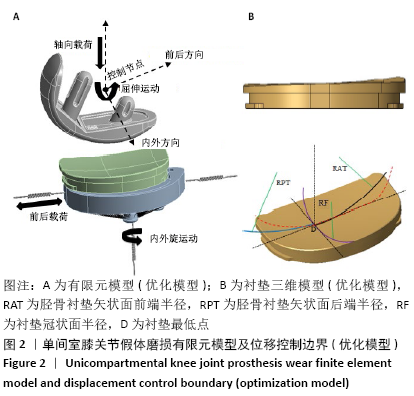

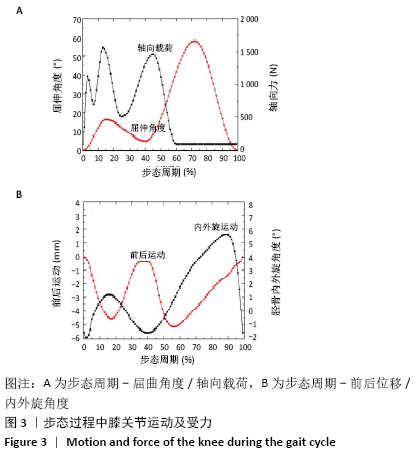

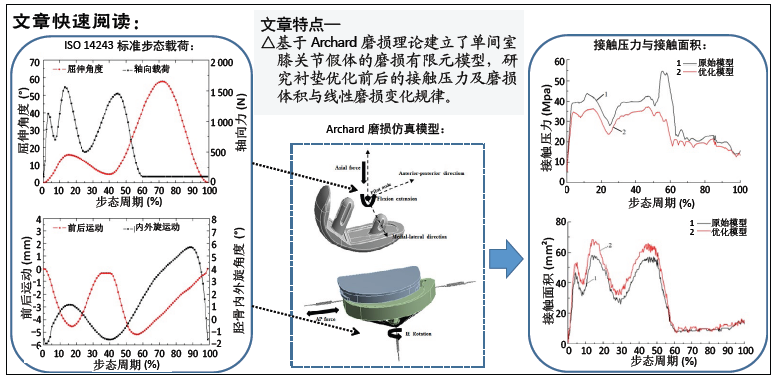

方法:基于Archard磨损理论建立了单间室膝关节假体的磨损有限元模型,研究了衬垫优化前后的接触压力及磨损性能变化规律。

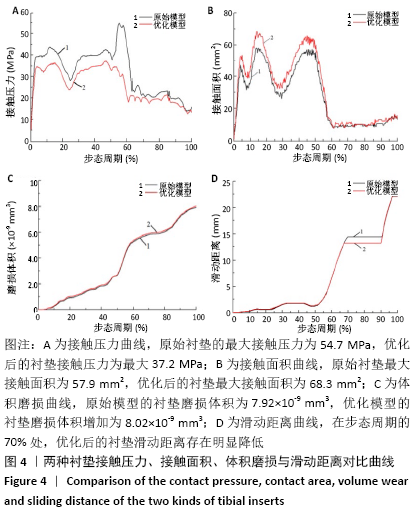

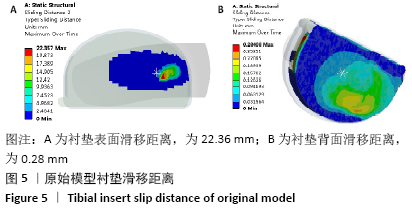

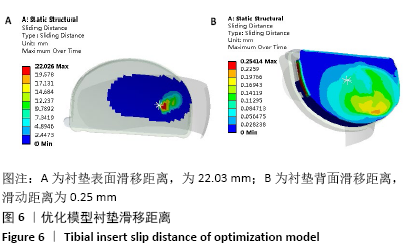

结果与结论:①在ISO标准步态载荷工况条件下,优化前后的衬垫接触压力分别为54.7 MPa和37.2 MPa,优化后的衬垫接触压力降低了32%;优化前后的衬垫线性磨损分别为4.38×10-5 mm和3.15×10-5 mm,优化后的衬垫线性磨损深度降低了28%;②结果表明优化后的衬垫可明显提高线性磨损性能,研究结果对单间室膝关节衬垫设计、磨损性能评估以及临床应用具有实际意义。

https://orcid.org/0000-0002-5038-0940 (王献抗)

中国组织工程研究杂志出版内容重点:人工关节;骨植入物;脊柱;骨折;内固定;数字化骨科;组织工程

中图分类号: