中国组织工程研究 ›› 2020, Vol. 24 ›› Issue (34): 5520-5525.doi: 10.3969/j.issn.2095-4344.2321

• 组织工程软骨材料Tissue-engineered cartilage • 上一篇 下一篇

颗粒软骨加α-氰基丙烯酸正丁酯胶结合3D打印技术辅助制作个性化耳支架

张 帆1,李高峰2,胡益高2,蔡立宏3

- 1湘潭爱思特医疗美容门诊部,湖南省湘潭市 411100;2湖南省人民医院(湖南师范大学附属第一医院)整形激光美容科,湖南省长沙市 410005;3长沙市第三医院放射影像科,湖南省长沙市 410007

Granule cartilage plus n-butyl α-cyanoacrylate glue combined with 3D printing technology for preparation of individualized ear scaffolds

Zhang Fan1, Li Gaofeng2, Hu Yigao2, Cai Lihong3

1Xiangtan Aist Medical Beauty Clinic, Xiangtan 411100, Hunan Province, China; 2Department of Plastic Laser Cosmetology, Hunan Provincial People’s Hospital (the First Affiliated Hospital of Hunan Normal University), Changsha 410005, Hunan Province, China; 3Department of Radiology, The Third Hospital of Changsha, Changsha 410007, Hunan Province, China

摘要:

文题释义:

α-氰基丙烯酸正丁酯:为组织胶水,临床上常用来作为组织粘连剂,这种黏合剂无毒、组织相容性好、粘连强度好,凝固后会形成一层带有网孔的生物膜,该网孔能通过组织液为软骨细胞提供营养物质,并不影响软骨细胞的存活。

颗粒软骨:常见于鼻整形中,取鼻中隔、鼻翼、耳郭或肋软骨,将其切成大小为0.5-1.5 mm颗粒状,用筋膜、脱细胞真皮或其他生物材料包裹后移植于填充区或不包裹直接进行移植填充。软骨材料是最接近真耳的支架材料。

背景:传统耳再造手术中耳支架的制作容易导致再造耳失真,3D打印技术使个性化、高仿真的小耳再造成为可能。

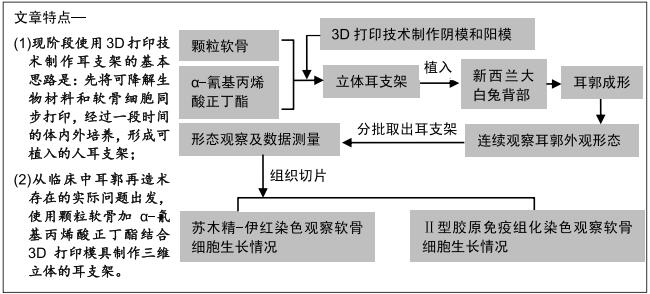

目的:探讨颗粒软骨加α-氰基丙烯酸正丁酯结合3D打印技术制作个性化耳支架的可行性。

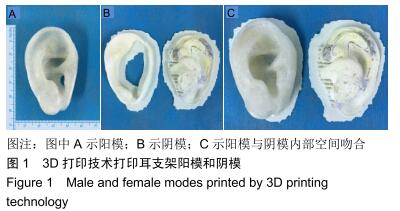

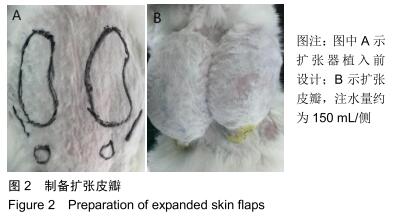

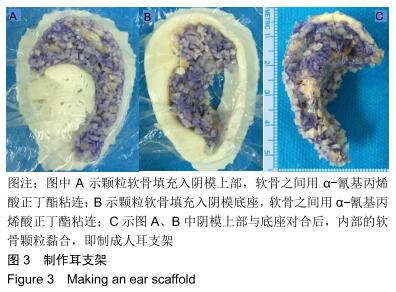

方法:根据耳畸形患者健侧耳制作患侧耳的3D耳支架阳模和阴模,将颗粒软骨用α-氰基丙烯酸正丁酯粘连放入阴模中,同时对比阳模微调,制成耳软骨支架后,将其植入新西兰大白兔背部,动态观察再造耳郭的形态,术后4,8,12周分批取出耳支架,组织学观察颗粒软骨间连接情况、软骨的存活状况等,免疫组化观察Ⅱ型胶原表达。动物实验获得湖南师范大学实验动物福利伦理审查委员会批准(批准号:201517)。

结果与结论:①大体观察:与术前比较,术后4,8,12周的再造耳郭长度、宽度、高度无明显变化,质量明显增加(P < 0.05);②组织学观察:颗粒软骨周围可见炎性细胞浸润,随着标本植入时间延长,炎性细胞逐渐减少,附着支架的筋膜中有较多血管生成;随着植入时间的延长,软骨膜内新生软骨细胞逐渐增多,体积逐渐增大,成熟软骨细胞逐渐增多;软骨碎片之间的α-氰基丙烯酸正丁酯未见明显分解,绝大部分软骨片之间仍被α-氰基丙烯酸正丁酯间隔,少部分软骨片之间有纤维连接形成,随着植入时间延长,软骨片之间的连接有增多的趋势;③免疫组化学观察:随着标本植入时间延长,Ⅱ型胶原表达逐渐增强;④结果表明:颗粒软骨加α-氰基丙烯酸正丁酯结合3D打印模具可以制作个性化耳支架。

ORCID: 0000-0002-7481-0722(张帆)

中国组织工程研究杂志出版内容重点:生物材料;骨生物材料; 口腔生物材料; 纳米材料; 缓释材料; 材料相容性;组织工程

中图分类号: