[1] SHEN G, FANG F, KANG C. Tribological Performance of Bioimplants: A Comprehensive Review. Nanotechnol Precis Eng. 2018;1(2):107-122.

[2] SHEN G, ZHANG JF, FANG FZ. In Vitro Evaluation of Artificial Joints: A Comprehensive Review. Adv Manufact. 2019;7:1-14.

[3] MATTEI L, Di PUCCIO F, PICCIGALLO B, et al. Lubrication and wear modelling of artificial hip joints: A review. Tribol Int. 2011;44(5): 532-549.

[4] VOUTAT C, NOHAVA J, WANDEL J, et al. The Dynamic Friction Coefficient of the Wet Bone-Implant Interface: Influence of Load, Speed, Material and Surface Finish. Biotribology. 2019;17:64-74.

[5] WANG C, ZHANG GQ, LI Z, et al. Tribological behavior of Ti-6Al-4V against cortical bone in different biolubricants. J Mech Behav Biomed Mater. 2019;90:460-471.

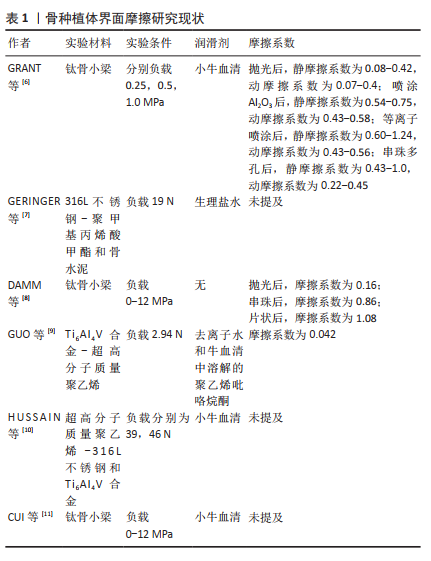

[6] GRANT JA, BISHOP NE, GOTZEN N, et al. Artificial composite bone as a model of human trabecular bone: the implant-bone interface. J Biomech. 2007;40(5):1158-1164.

[7] GERINGER J, ATMANI F, FOREST B. Friction–corrosion of AISI 316L/bone cement and AISI 316L/PMMA contacts: Ionic strength effect on tribological behaviour. Wear. 2009;267(5):763-769.

[8] DAMM NB, MORLOCK MM, BISHOP NE. Friction coefficient and effective interference at the implant-bone interface. J Biomech. 2015; 48(12):3517-3521.

[9] GUO Y, HAO ZX, WAN C. Tribological characteristics of polyvinylpyrrolidone (PVP) as a lubrication additive for artificial knee joint. Tribol Int. 2016;93:214-219.

[10] HUSSAIN O, SALEEM SS, AHMAD B. Friction and wear performance evaluation of UHMWPE using Taguchi based grey approach: A study on the influence of load and bio-serum lubrication. Mater Chem Phys. 2020;239:121918.

[11] CUI W, BIAN Y, ZENG H, et al. Structural and tribological characteristics of ultra-low-wear polyethylene as artificial joint materials. J Mech Behav Biomed Mater. 2020;104:103629.

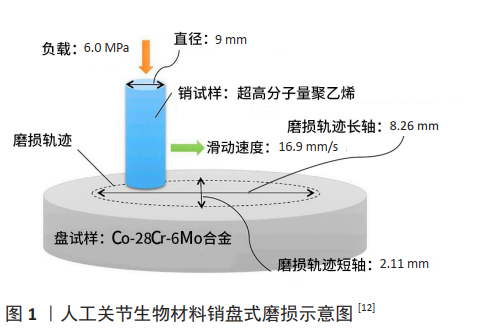

[12] NAKANISHI Y, NAKASHIMA Y, FUJIWARA Y, et al. Influence of surface profile of Co-28Cr-6Mo alloy on wear behaviour of ultra-high molecular weight polyethylene used in artificial joint. Tribol Int. 2018;118: 538-546.

[13] RAN QC, YANG WH, HU Y, et al. Osteogenesis of 3D printed porous Ti6Al4V implants with different pore sizes. J Mech Behav Biomed Mater.2018;84:1-11.

[14] BARTOLOMEU F, COSTA MM, GOMES JR, et al. Implant surface design for improved implant stability-A study on Ti6Al4V dense and cellular structures produced by Selective Laser Melting. Tribol Int. 2019; 129:272-282.

[15] POPOOLA API, PHUME L, AIGBODION VS. Laser ternary Hf-Nb-Zr composites coatings on Ti6Al4V alloy for biomedical application. Pro Inst Mech Eng Part C. 2018;233(3):1099-1107.

[16] ASRI RIM, Harun WSW, Samykano M, et al. Corrosion and surface modification on biocompatible metals: A review. Mater Sci Eng C. 2017;77:1261-1274.

[17] KURUP A, DHATRAK P, KHASNIS N. Surface modification techniques of titanium and titanium alloys for biomedical dental applications: A review. Mater Today Proc. 2020. doi.org/10.1016/j.matpr.2020.06.163

[18] HATAMLEH MM, WU XH, ALNAZZAWI A, et al. Surface characteristics and biocompatibility of cranioplasty titanium implants following different surface treatments. Dent Mater. 2018;34(4):676-683.

[19] ZHANG YJ, QIN YG, QING YA, et al. TiCuN solid solution coating: Excellent wear-resistant biocompatible material to protect artificial joint. Mater Lett. 2018;227:145-148.

[20] CHOUDHURY D, VRBKA M, MAMAT AB, et al. The impact of surface and geometry on coefficient of friction of artificial hip joints. J Mech Behav Biomed Mater. 2017;72:192-199.

[21] GHOSH S, ABANTERIBA S. Status of surface modification techniques for artificial hip implants. Sci Technol Adv Mater. 2016;17(1):715-735.

[22] YARIMITSU S, SASAKI S, MURAKAMI T, et al. Evaluation of lubrication properties of hydrogel artificial cartilage materials for joint prosthesis. Biosurf Biotribol. 2016;2(1):40-47.

[23] GHOSH S, CHOUDHURY D, PINGGUANMURPHY B. Lubricating ability of albumin and globulin on artificial joint implants: a tribological perspective. Int J Surf Sci Eng. 2016;10(2):193.

[24] ETSION I. State of the Art in Laser Surface Texturing. Adv Tribol. 2010; 761-762.

[25] TIAINEN L, ABREU P, BUCIUMEANU M, et al. Novel laser surface texturing for improved primary stability of titanium implants. J Mech Behav Biomed Mater. 2019;98:26-39.

[26] SAWANO H, WARISAWA S, ISHIHARA S. Study on long life of artificial joints by investigating optimal sliding surface geometry for improvement in wear resistance. Precis Eng. 2009;33(4):492-498.

[27] XU Y, LI ZP, ZHANG GQ, et al. Electrochemical corrosion and anisotropic tribological properties of bioinspired hierarchical morphologies on Ti-6Al-4V fabricated by laser texturing. Tribol Int. 2019;134:352-364.

[28] XU Y, LIU W, ZHANG GQ, et al. Friction stability and cellular behaviors on laser textured Ti-6Al-4V alloy implants with bioinspired micro-overlapping structures. J Mech Behav Biomed Mater. 2020;109: 103823.

[29] AHUIR-TORRES JI, ARENAS MA, PERRIE W, et al. Surface texturing of aluminium alloy AA2024-T3 by picosecond laser: Effect on wettability and corrosion properties. Surf Coat Technol. 2017;321:279-291.

[30] ARENAS MA, AHUIR-TORRES JI, GARCíA I, et al. Tribological behaviour of laser textured Ti6Al4V alloy coated with MoS2 and graphene. Tribol Int. 2018;128:240-247.

[31] COBLAS DG, FATU A, MAOUI A, et al. Manufacturing textured surfaces: State of art and recent developments. Proc Inst Mech Eng Part J. 2014; 229(1):3-29.

[32] ROY T, CHOUDHURY D, GHOSH S, et al. Improved friction and wear performance of micro dimpled ceramic-on-ceramic interface for hip joint arthroplasty. Ceram Int. 2015;41(1):681-690.

[33] CHYR A, QIU MF, SPELTZ J, et al. A patterned microtexture to reduce friction and increase longevity of prosthetic hip joints. Wear. 2014; 315(1-2):51-57.

[34] CHOUDHURY D, WALKER R, ROY T, et al. Performance of honed surface profiles to artificial hip joints: An experimental investigation. Int J Precis Eng Manufact. 2013;14(10):1847-1853.

[35] JAVIER GF, PLANELL JA, PADRóS A, et al. The effect of shot blasting and heat treatment on the fatigue behavior of titanium for dental implant applications. Dent Mater. 2007;23(4):486-491.

[36] HAVLIKOVA J, STRASKY J, VANDROVCOVA M, et al. Innovative surface modification of Ti-6Al-4V alloy with a positive effect on osteoblast proliferation and fatigue performance. Mater Sci Eng C. 2014;39:371-379.

[37] HE DQ, ZHENG SX, PU JB, et al. Improving tribological properties of titanium alloys by combining laser surface texturing and diamond-like carbon film. Tribol Int. 2015;82:20-27.

[38] ITO H, KANEDA K, YUHTA T, et al. Reduction of polyethylene wear by concave dimples on the frictional surface in artificial hip joints. J Arthroplasty. 2000;15(3):332-338.

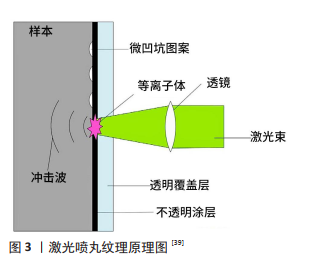

[39] LI KM, WANG YF, YU Z, et al. Process mechanism in laser peen texturing artificial joint material. Opt Lasers Eng. 2019;115:149-160.

[40] RAMSKOGLER C, WARCHOMICKA F, MOSTOFI S, et al. Innovative surface modification of Ti6Al4V alloy by electron beam technique for biomedical application. Mater Sci Eng C. 2017;78:105-113.

[41] CHOUDHURY D, URBAN F, VRBKA M, et al. A novel tribological study on DLC-coated micro-dimpled orthopedics implant interface. J Mech Behav Biomed Mater. 2015;45:121-131.

[42] CHING HA, CHOUDHURY D, NINE MJ, et al. Effects of surface coating on reducing friction and wear of orthopaedic implants. Sci Technol Adv Mater. 2016;15(1):506-512.

[43] JIN XD, YANG XK, WEI FR, et al. Research progress of surface modification materials and technology for medical titanium and titanium alloys. World Nonferrous Met. 2018;(7):265-266,268.

[44] NGUYEN-TRI P, NGUYEN TA, CARRIERE P, et al. Nanocomposite Coatings: Preparation, Characterization, Properties, and Applications. Int J Corros. 2018;2018:4749501.1-4749501.19.

[45] EGE D, DURU L, KAMALI AR, et al. Nitride, Zirconia, Alumina, and Carbide Coatings on Ti6Al4V Femoral Heads: Effect of Deposition Techniques on Mechanical and Tribological Properties. Adv Eng Mater. 2017;19(11):49-54.

[46] SONNTAG R, REINDERS J, KRETZER JP. What’s next? Alternative materials for articulation in total joint replacement. Acta Biomater. 2012;8(7):2434-2441.

[47] ŁAPAJ Ł, WENDLAND J, MARKUSZEWSKI J, et al. Retrieval analysis of titanium nitride (TiN) coated prosthetic femoral heads articulating with polyethylene. J Mech Behav Biomed Mater. 2015;55:127-139.

[48] ZUO J, XIE YN, ZHANG J, et al. TiN coated stainless steel bracket: Tribological, corrosion resistance, biocompatibility and mechanical performance. Surf Coat Technol. 2015;277:227-233.

[49] MARIN E, OFFOIACH R, LANZUTTI A, et al. Hybrid diffusive/PVD treatments to improve the tribological resistance of Ti-6Al-4V. Bio Med Mater Eng. 2013;23:601-612.

[50] ZHANG X, SUN S, SU D, et al. Structure and properties of TiCuN coatings by HCD assisted AIP. Surf Eng. 2016;32(3):223-228.

[51] MULLIGAN CP, GALL D. CrN–Ag self-lubricating hard coatings. Surf Coat Technol. 2005;200(5):1495-1500.

[52] KSTENBAUER H, FONTALVO GA, MITTERER C, et al. Tribological Properties of TiN/Ag Nanocomposite Coatings. Tribol Lett. 2008;30(1):53-60.

[53] LIU C, BI Q, MATTHEWS A. Tribological and electrochemical performance of PVD TiN coatings on the femoral head of Ti–6Al–4V artificial hip joints. Surf Coat Technol. 2003;163:597-604.

[54] BALLARRE J, MANJUBALA I, SCHREINER WH, et al. Improving the osteointegration and bone–implant interface by incorporation of bioactive particles in sol–gel coatings of stainless steel implants. Acta Biomater. 2010;6(4):1601-1609.

[55] TARNOWSKI M, KULIKOWSKI K, BOROWSKI T, et al. Influence of amorphous carbon layers on tribological properties of polyetheretherketone composite in contact with nitrided layer produced on Ti6Al4V titanium alloy. Diamond Relat Mater. 2017; 75:123-130.

[56] XIE D, LIU HJ, DENG XR, et al. Deposition of a-C:H films on UHMWPE substrate and its wear-resistance. Appl Surf Sci. 2009; 256(1):284-288.

[57] ŻóRAWSKI W, CHATYS R, RADEK N, et al. Plasma-sprayed composite coatings with reduced friction coefficient. Surf Coat Technol. 2008; 202(18):4578-4582.

[58] BALANI K, CHEN Y, HARIMKAR SP, et al. Tribological behavior of plasma-sprayed carbon nanotube-reinforced hydroxyapatite coating in physiological solution. Acta Biomater. 2007;3(6):944-951.

[59] DONG ZL, KHOR KA, QUEK CH, et al. TEM and STEM analysis on heat-treated and in vitro plasma-sprayed hydroxyapatite/Ti-6Al-4V composite coatings. Biomaterials. 2003;24(1):97-105.

[60] LIANG H, SHI B, FAIRCHILD A, et al. Applications of plasma coatings in artificial joints: an overview. Vacuum. 2004;73(3-4):317-326.

[61] JIN J, CHEN YB, GAO KW, et al. The effect of ion implantation on tribology and hot rolling contact fatigue of Cr4Mo4Ni4V bearing steel. Appl Surf Sci. 2014;305:93-100.

[62] ZHOU ZF, LI KY, SHUM P, et al. Surface gradient CoCrMo alloy generated by carbon ion implantation with enhanced tribocorrosion resistance. Surf Coat Technol. 2017;320:590-594.

[63] PARK WW, KIM EK, JEON JH, et al. Wear of UHMWPE against nitrogen-ion-implanted and NbN-coated Co–Cr–Mo alloy formed by plasma immersion ion implantation and deposition for artificial joints. Appl Surf Sci. 2012;258(20):8228-8233.

[64] NAVINSEK B, SEAL S. Transition metal nitride functional coatings. JOM. 2001;53(9):51-54.

[65] COADOU CL, KARST N, EMIEUX F, et al. Assessment of ultrathin yttria-stabilized zirconia foils for biomedical applications. J Mater Sci. 2017; 50(18):1-11.

[66] SONG J, LIU YH, LIAO ZH, et al. Wear studies on ZrO2-filled PEEK as coating bearing materials for artificial cervical discs of Ti6Al4V. Mater Sci Eng C Mater Biol Appl. 2016;69:985-994.

[67] MCCALDEN RW, CHARRON KD, DAVIDSON RD, et al. Damage of an Oxinium femoral head and polyethylene liner following ‘routine’ total hip replacement. J Bone Jt Surg Br Vol. 2011;93(3):409.

[68] SUNDARARAJAN G, KRISHNA LR. Mechanisms underlying the formation of thick alumina coatings through the MAO coating technology. Surf Coat Technol. 2003;167(2-3):269-277. |

文题释义:

文题释义:

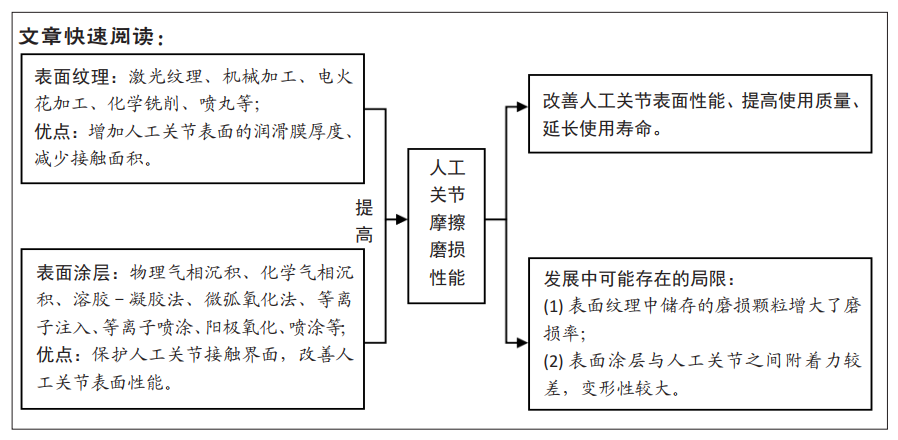

随着骨植入体研究领域的快速发展,研发一种高性能的人工关节材料具有重要的意义。目前常用于人工关节的材料主要有金属材料、陶瓷材料、高分子材料等。其中钛和钛合金材料不仅弹性模量与自体骨接近,而且具有优异的机械性能和生物相容性,在骨植入体领域得到了广泛应用,如人工支架、人工关节、义齿[13-14],但钛合金表面硬度较低、耐磨性较差,在体内会释放金属离子(如Al离子和V离子),易引起骨溶解和无菌性松动,这在一定程度上限制了钛合金材料在骨植入体领域的应用。有研究表明,通过表面处理技术在钛合金表面制备的硬质涂层,可以有效提高钛合金表面的摩擦学性能。POPOOLA等[15]通过激光熔覆技术在钛合金表面制备了生物陶瓷涂层,发现该生物陶瓷涂层显著减少了钛合金材料中V离子和Al离子的释放量,并显著改善了钛合金材料的硬度、耐蚀性和耐磨性。通过对人工关节材料进行表面处理可以有效改善人工关节材料的生物相容性、耐腐蚀性、耐磨性等性能[16]。对锆铌合金进行表面陶瓷化处理可以获取一种兼有金属与陶瓷材料优点的黑晶材料,该材料具有高硬度、超强耐磨性、无脆性的特点,在人工关节的使用中可以显著减少对骨水泥的磨损。有研究表明,采用表面处理技术对钴基合金进行处理不仅可以有效减少CoCrMo合金中离子的毒性,而且可以显著提高表面硬度和耐磨性。KURUP等[17]总结了近年来应用于钛植入体中的表面处理技术,指出酸腐蚀、磨削、氧化、氮化等表面处理技术具有一定的发展前景。HATAMLEH等[18]研究了机械抛光、70%酸蚀刻、喷砂等不同表面处理技术对钛合金样品的摩擦磨损性能的影响。

随着骨植入体研究领域的快速发展,研发一种高性能的人工关节材料具有重要的意义。目前常用于人工关节的材料主要有金属材料、陶瓷材料、高分子材料等。其中钛和钛合金材料不仅弹性模量与自体骨接近,而且具有优异的机械性能和生物相容性,在骨植入体领域得到了广泛应用,如人工支架、人工关节、义齿[13-14],但钛合金表面硬度较低、耐磨性较差,在体内会释放金属离子(如Al离子和V离子),易引起骨溶解和无菌性松动,这在一定程度上限制了钛合金材料在骨植入体领域的应用。有研究表明,通过表面处理技术在钛合金表面制备的硬质涂层,可以有效提高钛合金表面的摩擦学性能。POPOOLA等[15]通过激光熔覆技术在钛合金表面制备了生物陶瓷涂层,发现该生物陶瓷涂层显著减少了钛合金材料中V离子和Al离子的释放量,并显著改善了钛合金材料的硬度、耐蚀性和耐磨性。通过对人工关节材料进行表面处理可以有效改善人工关节材料的生物相容性、耐腐蚀性、耐磨性等性能[16]。对锆铌合金进行表面陶瓷化处理可以获取一种兼有金属与陶瓷材料优点的黑晶材料,该材料具有高硬度、超强耐磨性、无脆性的特点,在人工关节的使用中可以显著减少对骨水泥的磨损。有研究表明,采用表面处理技术对钴基合金进行处理不仅可以有效减少CoCrMo合金中离子的毒性,而且可以显著提高表面硬度和耐磨性。KURUP等[17]总结了近年来应用于钛植入体中的表面处理技术,指出酸腐蚀、磨削、氧化、氮化等表面处理技术具有一定的发展前景。HATAMLEH等[18]研究了机械抛光、70%酸蚀刻、喷砂等不同表面处理技术对钛合金样品的摩擦磨损性能的影响。