| [1] Li C,Liu D,Zhang Z,et al.Triple point-mutants of hypoxia-inducible factor-1α accelerate in vivo angiogenesis in bone defect regions.Cell Biochem Biophys. 2013;67(2):557-566.

[2] Seebach C,Henrich D,Wilhelm K,et al.Endothelial progenitor cells improve directly and indirectly early vascularization of mesenchymal stem cell-driven bone regeneration in a critical bone defect in rats.Cell Transplant.2012;21(8):1667-1677.

[3] Healy KE,Guldberg RE.Bone tissue engineering.J Musculoskelet Neuronal Interact.2007;7(4):328.

[4] Bose S,Roy M,Bandyopadhyay A.Recent advances in bone tissue engineering scaffolds. Trends Biotechnol.2012;30(10): 546-554.

[5] Watson BM,Kasper FK,Engel PS,et al.Synthesis and Characterization of Injectable, Biodegradable, Phosphate- Containing,Chemically Cross-Linkable, Thermoresponsive Macromers for Bone Tissue Engineering.Biomacromolecules. 2014;15(5):1788-1796.

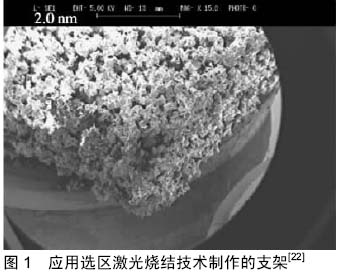

[6] Pereira TF,Silva MA,Oliveira MF,et al.Effect of process parameters on the properties of selective laser sintered Poly (3-hydroxybutyrate) scaffolds for bone tissue engineering: This paper analyzes how laser scan spacing and powder layer thickness affect the morphology and mechanical properties of SLS-made scaffolds by using a volume energy density function. Virtual Phys Prototyp.2012;7(4):275-285.

[7] Bose S,Vahabzadeh S,Bandyopadhyay A. Bone tissue engineering using 3D printing. Mater Today.2013;16(12): 496-504.

[8] Miranda SC,Silva GA,Hell RC,et al.Three-dimensional culture of rat BMMSCs in a porous chitosan-gelatin scaffold: A promising association for bone tissue engineering in oral reconstruction. Arch Oral Biol.2011;56(1):1-15.

[9] Pandithevan P,Kumar GS.Finite element analysis of a personalizedfemoral scaffold with designed microarchitecture. Proc Inst Mech Eng H.2010;224(7):877-889.

[10] Nikzad M,Masood SH,Sbarski I.Thermo-mechanical properties of a highly filled polymeric composites for fused deposition modeling.Mater Design.2011;32(6):3448-3456.

[11] Dalton PD,Vaquette C,Farrugia BL,et al. Electrospinning and additive manufacturing: converging technologies.Biomater Sci.2013;1(2):171-185.

[12] Domingos M,Chiellini F,Gloria A,et al.Effect of process parameters on the morphological and mechanical properties of 3D Bioextruded poly (?-caprolactone) scaffolds. Rapid Prototyping J.2012;18(1):56-67.

[13] Guneta V,Wang JK,Maleksaeedi S,et al.Three Dimensional Printing of Titanium for Bone Tissue Engineering Applications: A Preliminary Study.J Biomimet Biomater Biomed Eng.2014; 21: 101-115.

[14] Schantz JT,Brandwood A,Hutmacher DW,et al.Osteogenic differen-tiation of mesenchymal progenitor cells in computer designed fibrin-polymer-ceramic scaffolds manufactured by fused deposition model-ing. J Mater Sci Mater Med.2005; 16(9): 807-819.

[15] Xu N,Ye X,Wei D,et al.3D artificial bones for bone repair prepared by computed tomography-guided fused deposition modeling for bone repair.ACS Appl Mater Interfaces.2014; 6(17): 14952-14963.

[16] ElomaaL,Teixeira S,Hakala R,et al.Preparation of poly (ε-caprolactone)-based tissue engineering scaffolds by stereolithography.Acta Biomaterialia.2011;7(11): 3850-3856.

[17] Zorlutuna P,Annabi N,Camci‐Unal G,et al.Microfabricated biomaterials for engineering 3D tissues.Adv Mater.2012; 24(14): 1782-1804.

[18] Kim JY,Cho DW.Blended PCL/PLGA scaffold fabrication using multi-head deposition system.Microelectron Eng.2009;86(4): 1447-1450.

[19] Shin JH,Lee JW,Jung JH, et al. Evaluation of cell proliferation and differentiation on a poly (propylene fumarate) 3D scaffold treated with functional peptides.J Mater Sci.2011;46(15): 5282-5287.

[20] Jansen J,Melchels FP,Grijpma DW,et al. Fumaric acid monoethyl ester-functionalized poly (D, L-lactide)/ N-vinyl-2- pyrrolidone resins for the preparation of tissue engineering scaffolds by stereolithography. Biomacromolecules. 2009; 10(2):214-220.

[21] Eshraghi S,Das S.Micromechanical finite-element modeling and experimental characterization of the compressive properties of polycaprolactone–hydroxyapatite composite scaffolds prepared by selective laser sintering for bone tissue engineering.Acta Biomaterialia.2012;8(8):3138-3143.

[22] Tay BY,Zhang SX,Myint MH,et al.Processing of polycaprolactone porous structure for scaffold development.J Mater Process Technol.2007;182(1-3):117-121.

[23] Feng P,Wei P,Shuai C,et al.Characterization of Mechanical and Biological Properties of 3-D Scaffolds Reinforced with Zinc Oxide for Bone Tissue Engineering. PloS One.2014;9(1): e87755.

[24] Chen CH,Shyu VB,Chen JP,et al.Selective laser sintered poly-ε-caprolactone scaffold hybridized with collagen hydrogel for cartilage tissue engineering. Biofabrication.2014; 6(1):015004.

[25] Tarafder S,Balla VK,Davies NM,et al.Microwave‐sintered 3D printed tricalcium phosphate scaffolds for bone tissue engineering.J Tissue Eng Regen Med.2013;7(8):631-641.

[26] Trachtenberg JE,Mountziaris PM,Miller JS,et al.Open‐source three‐dimensional printing of biodegradable polymer scaffolds for tissue engineering. J Biomed Mater Res A.2014; 102(12): 4326-4335.

[27] Utela B,Anderson RL,Kuhn H.Advanced ceramic materials and processes for three-dimensional printing (3DP).Solid Freeform Fabr Symp Proc.2006;17: 290-303.

[28] Tarafder S,Davies NM,Bandyopadhyay A,et al. 3D printed tricalcium phosphate bone tissue engineering scaffolds: effect of SrO and MgO doping on in vivo osteogenesis in a rat distal femoral defect model.Biomater Sci.2013;1(12):1250-1259.

[29] Farzadi A, Solati-Hashjin M, Asadi-Eydivand M, et al.Effect of layer thickness and printing orientation on mechanical properties and dimensional accuracy of 3D printed porous samples for bone tissue engineering.PLoS One.2014;9(9): e108252.

[30] Tarafder S,Bose S.Polycaprolactone-Coated 3D Printed Tricalcium Phosphate Scaffolds for Bone Tissue Engineering: In Vitro Alendronate Release Behavior and Local Delivery Effect on In Vivo Osteogenesis.ACS Appl Mater Interfaces. 2014;6(13): 9955-9965.

[31] Gatto M,Memoli G,Shaw A,et al.Three-Dimensional Printing (3DP) of neonatal head phantom for ultrasound: Thermocouple embedding and simulation of bone.Med Eng Phys.2012; 34(7):929-937.

[32] Liu FH. Fabrication of Bioceramic Bone Scaffolds for Tissue Engineering. J Mater Eng Perform.2014;23(10):3762-3769.

[33] Bose S,Vahabzadeh S,Bandyopadhyay A.Bone tissue engineering using 3D printing. Mater Today.2013;16(12): 496-504.

[34] Bose S,Roy M,Bandyopadhyay A.Recent advances in bone tissue engineering scaffolds.Trends Biotechnol.2012;30(10): 546-554.

[35] Popov VK,Komlev VS,Chichkov BN.Calcium phosphate blossom for bone tissue engineering.Mater Today.2014;17(2): 96-97.

[36] Nakayama Y,Takewa Y,Sumikura H,et al.In‐body tissue‐engineered aortic valve (Biovalve type VII) architecture based on 3D printer molding.J Biomed Mater Res B Appl Biomater. 2015;103(1):1-11.

[37] Waran V,Narayanan V,Karuppiah R,et al.Utility of multimaterial 3D printers in creating models with pathological entities to enhance the training experience of neurosurgeons: Technical note.J Neurosurg.2014;120(2):489-492. |