2.1 粘接溶液/打印粉末层的液固作用过程分析 粘接溶液在点阵喷洒时能否形成稳定可控的液滴是3D打印顺利成型的前提。液滴成形状态主要取决于粘接溶液的黏度、密度及表面张力等物化参数,其可由参数Z进行判断[16]:

其中:

式中,ρ为密度(kg/m3);μ为黏度(Pa?s);γ为表面张力(N/m);ν为液滴运动速度(6 m/s);d为喷孔直径(4.1× 10-5 m)。

尽管无定形磷酸钙的水化反应是其成功实现打印成型的根本性前提,但是粘接溶液的液滴在粉末层多孔体系中毛细渗透及其对无定形磷酸钙颗粒表面的铺展润湿等液固交互作用行为也是影响骨成品结构和性能的决定性因素。液滴与无定形磷酸钙粉末层的交互作用涉及到十分复杂的物理化学过程,受到打印参数(喷洒速度、粉末层厚度、饱和度等)、粘接溶液的物化参数(黏度、表面张力、黏性力等)、无定形磷酸钙粉末的性质(颗粒形状、粒径大小与分布、粉末层孔隙结构等)、无定形磷酸钙水化反应状态等多种因素的交互影响,从根本上决定了打印骨成品各种性能[18-20]。

粘接溶液的液滴以点阵方式均匀喷洒到铺好的无定形磷酸钙粉末层表面,首先液滴会对粉末层产生一定的冲击,然后液滴迅速在粉末层的孔隙结构中逐步铺展和毛细渗透,此时无定形磷酸钙颗粒表面逐渐被水分子润湿,并且立即持续不断地发生水化反应,导致所生成的羟基磷灰石晶体相互交错搭接,直至形成三维网状结构。

由于粘接溶液的主体成分为纯水,所以其可充分快速润湿无定形磷酸钙粉末颗粒表面。因此,液滴/粉末层交互作用的主要矛盾即为:在液滴喷洒冲击粉末层表面时,不发生溅射的前提下液滴的动能是否成功克服其自身流动产生的黏性阻力及其与颗粒表面的摩擦力,从而在粉末层中顺利地铺展与毛渗透。参考液滴撞击平板的数学模型,以参数K判断是否发生溅射(在一定范围内,K值越大,越易出现溅射)[21],并以We衡量液滴的动能(在一定范围内,We越大,液滴越易克服阻力而顺利流动)[19-20]:

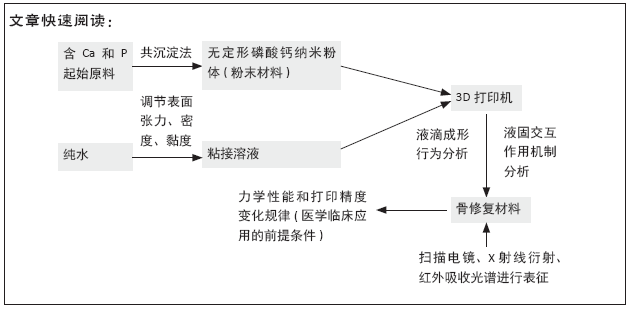

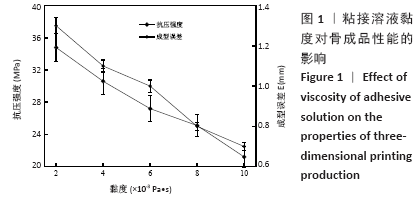

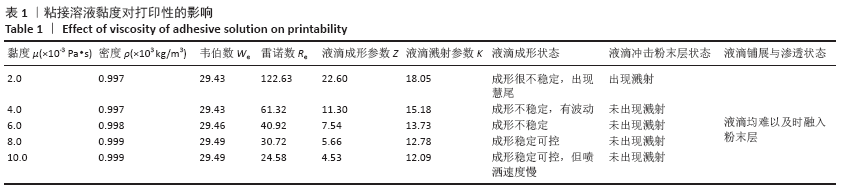

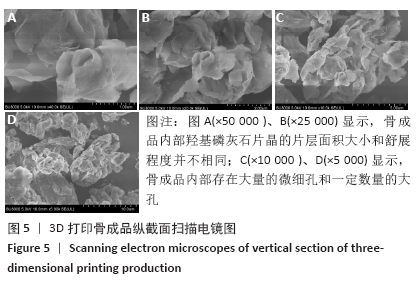

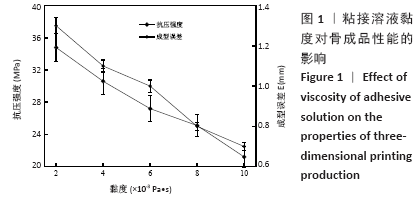

2.2 粘接溶液黏度的影响规律 由于EG的增稠效果十分优异,所以首先单独加入很少量的EG,即可调节粘接溶液达到所需黏度(调节过程中密度几乎不变化,而表面张力稍有变化),然后加入适量的流平剂控制表面张力为0.05 N/m(加入很少量的流平剂即可极其有效地调节黏度,此时密度和黏度几乎不变化);此时打印过程状态如表1所示,骨成品的性能变化如图1所示。

由表1可知,当Z<7.54时,粘接溶液经打印喷头均可形成稳定可控的液滴;当Z≥7.54时,液滴成形开始不稳定,且随着Z值继续变大而甚至出现慧尾,这主要是因为当黏度过小时,粘接溶液在喷嘴处凸起变形的动力太大,迅速从型腔传播至喷嘴处并聚集膨胀,从而导致单位时间内液滴体积偏大[16]。当黏度过大时,粘接溶液在喷腔拉伸及其在喷嘴处被拉断的阻力都较大,导致液滴成形速度降低,从而拖慢了喷洒速度和打印成型速度。同时,由表1还可知,一方面当K≤15.18时,液滴冲击粉末层时不会发生溅射,此时有利于成型精度的提高。另一方面,表1中所有粘接溶液都难以及时融入粉末层,这可能主要是因为粘接溶液的动能均较小(We≤29.49),难以克服阻力而顺利地在粉末层上铺展与渗透。

由图1可知,随着粘接溶液黏度的增加,打印骨成品的抗压强度和成型误差都逐渐变小,这主要是因为粘接溶液的黏度越大(此时其动能都较小,可由We≤29.49判断),则液滴在粉末层中渗透和铺展速度越慢;一方面,液滴越难以均匀充分地渗入所需成型区域的孔隙结构中,使得部分无定形磷酸钙颗粒没有接触到足够数量的水分子而无法充分发生水化反应,从而导致抗压强度逐渐降低;另一方面,由于无定形磷酸钙水化反应能力突出,其反应速度快于液滴铺展速度,因此液滴在向成型区域的四周扩展之前即已全部参与水化反应,所以成型误差随着黏度增加而减小(即成型精度逐渐变好)。综合权衡液滴成形情况、液固交互作用状态、骨成品的力学性能与成型精度,粘接溶液的最佳黏度为 8.0×10-3 Pa?s。

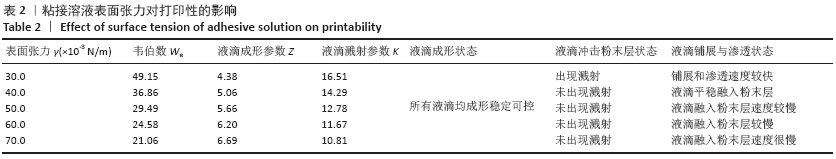

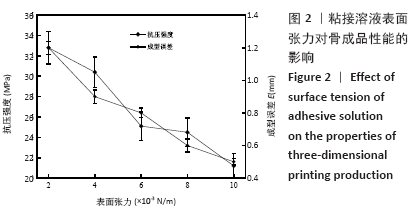

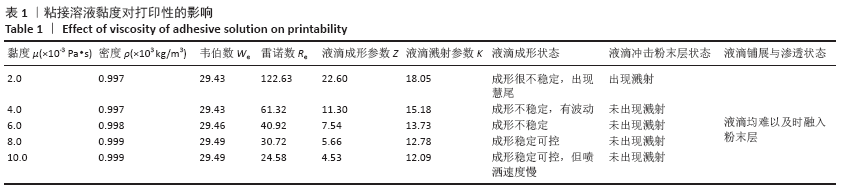

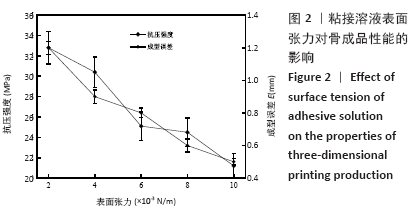

2.3 粘接溶液表面张力的影响规律 首先加入适量EG控制粘接溶液的黏度为8.0×10-3 Pa?s,对应密度为0.999×103 kg/m3且几乎不变化,此时Re=30.72且保持不变,然后加入适量的流平剂调节表面张力;此时打印过程状态如表2所示,骨成品的性能变化如图2所示。

结合表1,2可知,因为Z < 7.54时,所以均可形成稳定可控的液滴;同时当K≤15.18时液滴喷洒冲击粉末层时不会发生溅射。另外,当We≥36.86时此时液滴动能较大,能够在粉末层中及时顺利地铺展与渗透。

由图2可知,随着粘接溶液表面张力的增加,打印骨成品的抗压强度和成型误差均逐步减小。结合表1和表2,当表面张力为30.0×10-3 N/m时,不仅液滴冲击会产生溅射(K>15.18),导致骨成品出现翅曲、尺寸变形甚至破损等成型缺陷,而且由于动能过大(We=49.15),液滴在与无定形磷酸钙发生水化反应之前即部分地向成型区域的四周扩展,导致成型精度差。当表面张力大于40.0×10-3 N/m时,动能均较小(We≤29.49),铺展和渗透的能量都较低,因此不会扩展出成型区域,所以成型误差随着We的减小而降低;但是,液滴的动能越小其越难以顺利渗透分布于成型区域孔隙结构,导致更多的无定形磷酸钙颗粒无法充分接触到水,使得骨成品的抗压强度越低。因为在力学性能优异的前提下为了能与骨缺损部位很好地吻合,要求打印精度越高越好,此时骨成品才具备实际应用价值,所以综合权衡液固交互作用情况、抗压强度及成型误差,粘接溶液的最佳表面张力为40.0×10-3 N/m,此时骨成品的抗压强度为30.4 MPa,成型误差仅为0.9 mm,基本满足部分场合下骨缺损修复需求。

2.4 结构表征

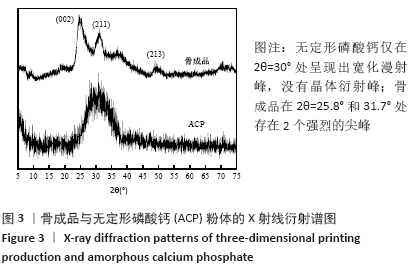

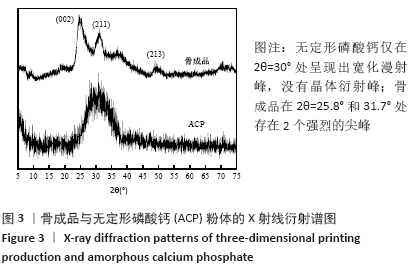

2.4.1 X射线衍射表征分析 由上述分析可知,粘接溶液最佳参数:黏度为8.0×10-3 Pa?s,表面张力为40.0×10-3 N/m,对应密度为0.999×103 kg/m3。最优参数下打印制取的骨成品与无定形磷酸钙粉体的X射线衍表征如图3所示。

由图3可知,无定形磷酸钙仅在2θ=30°处呈现出宽化漫射峰,没有晶体衍射峰,表明无定形磷酸钙不含其他晶体物质,即为纯的无定形状态[22]。骨成品在2θ=25.8°和31.7°处存在2个强烈的尖峰,它们是羟基磷灰石典型的特征衍射峰,分别对应着(002)和(211)晶面,表明无定形磷酸钙已经明显通过水化反应相变成羟基磷灰石晶体[23];但是(112)、(300)等其他羟基磷灰石晶面衍射峰几乎消失,仅(213)晶面衍射峰略微明显,这主要是由于骨成品中还存在相当数量的无定形磷酸钙所造成的:在基于离散堆积成型的粉末粘接类3D打印成型过程中,一方面,作为粘接溶液的纯水用量显著少于无定形磷酸钙快速水化所需的水量;另一方面,水分子在粉末层孔隙结构中流动时与无定形磷酸钙颗粒接触而发生水化反应,所生成的羟基磷灰石晶体形成一层膜,从而明显降低了水分子向粉末层内部渗透;这2方面因素导致距离孔隙结构较远区域中的无定形磷酸钙在较长一段时间内尚未水化相变(如果骨成品的静置时间足够长,所有无定形磷酸钙颗粒最终会全部转化羟基磷灰石晶体)。当将包含一定数量无定形磷酸钙的骨成品植入生物体后,其生物相容性、降解速率等性能都会显著增加[8]。

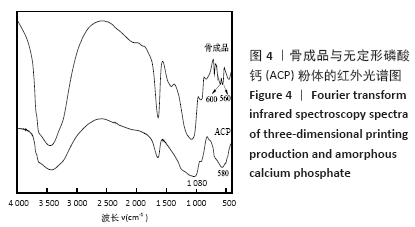

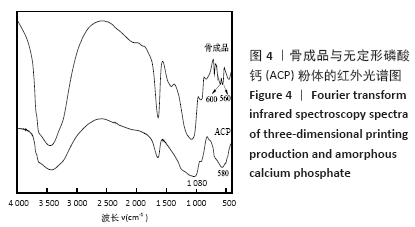

2.4.2 傅里叶红外光谱表征分析 最优参数下打印制取的骨成品与无定形磷酸钙粉体的傅里叶红外光谱表征如图4所示。

图4中,1 080 cm-1处为PO43-非对称伸缩振动吸收峰(ν3),表明无定形磷酸钙和骨成品都是磷酸钙。无定形磷酸钙红外光谱图中580 cm-1处为PO43-弯曲振动吸收峰(ν4),其没有发生分裂,表明无定形磷酸钙确为无定形相。而骨成品则在此处相当程度地劈裂成560 cm-1和600 cm-1 2个峰,表明无定形磷酸钙确实已基本相变成羟基磷灰石晶体[23-24];但由于其未彻底劈裂,说明尚有一部分无定形磷酸钙仍处于无定形状态,这与X射线衍射分析结果互相印证。

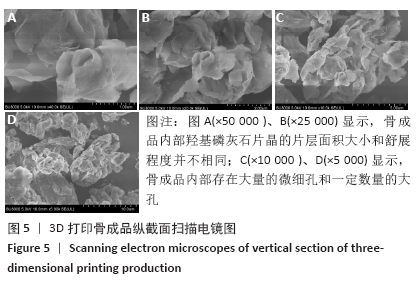

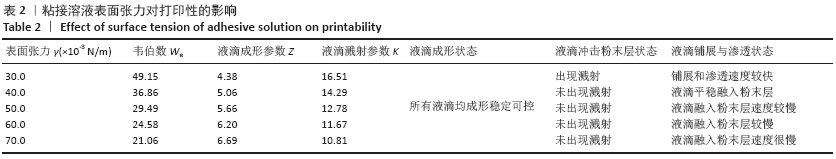

2.4.3 微观形貌特征分析 最优参数下打印制取的骨成品的纵向断截面微观表征如图5所示。

由图5可知,骨成品中无定形磷酸钙水化产物羟基磷灰石晶体微观形貌主要呈现不规则的片状,片晶互相粘接成网状整体,从而赋予骨成品较好的力学性能[13]。图5A,B显示,骨成品内部羟基磷灰石片晶的片层面积大小和舒展程度并不相同,这主要是由于不同区域的无定形磷酸钙颗粒与粘接溶液中水分子的接触程度不同所导致的;越靠近孔隙结构的无定形磷酸钙颗粒接触到的水分子越多,其水化反应越充分,所生成的羟基磷灰石片状结构越完善,即片层面积和舒展程度越大。图5C,D显示,正是因为羟基磷灰石片晶的程度程度不一,所以它们在粉末层原有的孔隙结构中彼此交错生长搭接,导致骨成品内部存在大量的微细孔和一定数量的大孔,给细胞增长提供充足的生长空间,表明其骨传导性能比较优异[1,5,14-15]。