| [1]Pauly S,Back DA,Kaeppler K,et al.Influence of statins locally applied from orthopedic implants on osseous integration.BMC Musculoskelet Disord. 2012;26(13): 208. [2]Rentsch C,Schneiders W,Manthey S,et al. Comprehensive histological evaluation of bone implants. Biomatter.2014;4pii:e27993[3]Amer MA,Rodríguez PA,Renou SJ,et al.Use of Human Fascia Lata in Rat Calvarial Bone Defects.Acta Odontol Latinoam.2015;28(3):231-235.[4]Balla VK,Martinez S,Rogoza BT,et al.Quasi-static Torsional Deformation Behavior of Porous Ti6Al4V alloy.Mater Sci Eng C Mater Biol Appl. 2011;31(5): 945-949.[5]Lewallen EA,Riester SM,Bonin CA,et al.Biological strategies for improved osseointegration and osteoinduction of porous metal orthopedic implants. Tissue Eng Part B Rev.2015;21(2):218-230.[6]Frydman A,Simonian K.Review of models for titanium as a foreign body.J Calif Dent Assoc. 2014;42(12):829-833.[7]Jemat A,Ghazali MJ,Razali M,et al.Surface Modifications and Their Effects on Titanium Dental Implants.Biomed Res Int.2015;2015:791725. [8]García-Rey E,García-Cimbrelo E.Clinical and radiographic results and wear performance in different generations of a cementless porous-coated acetabular cup.Int Orthop.2008;32(2):181-187.[9]Hirota M,Shima T,Sato I,et al.Development of a biointegrated mandibular reconstruction device consisting of bone compatible titanium fiber mesh scaffold.Biomaterials.2016;75:223-236. [10]Ratnayake JT,Mucalo M,Dias GJ.Substituted hydroxyapatites for bone regeneration: A review of current trends.J Biomed Mater Res B Appl Biomater. 2016.doi: 10.1002/jbm.b.33651. [Epub ahead of print][11]Yamako G,Chosa E,Totoribe K,et al.Trade-offbetween stress shielding and initial stability on an anatomical cementless stem shortening: in-vitro biomechanical study.ed Eng Phys.2015;37(8):820-825.[12]Zhang BG,Myers DE,Wallace GG,et al.Bioactive Coatings for Orthopaedic Implants—Recent Trendsin Development of Implant Coatings.Int J Mol Sci.2014; 15(7):11878-11921.[13]Eltorai AE,Nguyen E,Daniels AH.Three-Dimensional Printing in Orthopedic Surgery. Orthopedics. 2015; 38(11):684-687.[14]Cronskar M,Backstrom M,Rannar LE.Production of customized hip stem prostheses –a comparison between conventional machiningand electron beam melting (EBM). Rapid Prototyping J. 2013;19(5):365-372.[15]Xu J,Weng XJ,Wang X,et al.Potential use of porous titanium-niobium alloy in orthopedic implants: preparation and experimental study of its biocompatibility in vitro.PLoS One.2013;8(11):e79289.[16]Balla VK,Banerjee S,Bose S,et al.Direct laser processing of a tantalum coating on titanium for bone replacement structures.Acta Biomater. 2010;6(6):2329-2334. [17]Matena J,Petersen S,Gieseke M,et al.SLM produced porous titanium implant improvements for enhanced vascularization and osteoblast seeding.Int J Mol Sci. 2015;16(4):7478-7492.[18]Asa'ad F,Pagni G,Pilipchuk SP,et al.3D-Printed Scaffolds and Biomaterials: Review of Alveolar Bone Augmentation and Periodontal Regeneration Applications.Int J Dent. 2016;2016:1239842. [19]Polo-Corrales L,Latorre-Esteves M,Ramirez-Vick JE.Scaffold design for bone regeneration.J Nanosci Nanotechnol.2014;14(1):15-56.[20]Cheng A,Humayun A,Cohen DJ,et al. Additively Manufactured 3D Porous Ti-6Al-4V Constructs Mimic Trabecular BoneStructure and Regulate Osteoblast Proliferation, Differentiation and LocalFactor Production in a Porosity and Surface Roughness Dependent Manner.Biofabrication.2014;6(4):045007.[21]Lv J,Jia Z,Li J,et al.Electron Beam Melting Fabrication of Porous Ti6Al4VScaffolds: Cytocompatibility and Osteogenesis.Adv Eng Mater.2015;17(9):1391-1398.[22]Markhoff J,Wieding J,Weissmann V,et al.Influence of Different Three-Dimensional Open Porous TitaniumScaffold Designs on Human Osteoblasts Behavior in Static andDynamic Cell Investigations. Materials.2015;8(8):5490-5507.[23]Taniguchi N,Fujibayashi S,Takemoto M,et al.Effect of pore size on bone ingrowth into porous titanium implantsfabricated by additive manufacturing: An in vivo experiment.Mater Sci EngC.2016;59:690-701.[24]Biemond JE,Aquarius R,Verdonschot N,et al.Frictional and bone ingrowth properties of engineered surfacetopographies produced by electron beam technology.Arch Orthop Trauma Surg. 2011;131(5): 711-718.[25]Prananingrum W,Naito Y,Galli S,et al.Bone ingrowth of various porous titanium scaffolds produced by a moldless and space holder technique: an in vivo study in rabbits.Biomed Mater.2016;11(1):015012.[26]Loh QL,Choong C.Three-Dimensional Scaffoldsfor Tissue Engineering Applications:Role of Porosity and Pore Size. Tissue Eng Part B Rev.2013;19(6):485-502.[27]Jeon H,Lee H,Kim G.A surface-modified poly(?-caprolactone) scaffold comprising variable nanosized surface-roughnessusing a plasma treatment.Tissue Eng Part C Methods. 2014;20(12):951-963.[28]Li JP,Habibovic P,van den Doel M,et al.van Blitterswijk, Klaas de Groot. Bone ingrowth in poroustitanium implants producedby 3D fiber deposition. Biomaterials. 2007;28(18):2810-2820.[29]Nover AB,Lee SL,Georgescu MS,et al.Porous titanium bases for osteochondral tissue engineering.Acta Biomater.2015;27:286-293. [30]Van der Stok J,Van der Jagt OP,Amin Yavari S,et al.Selective laser melting-produced porous titanium scaffolds regenerate bone in critical size cortical bone defects.J Orthop Res.2013;31(5):792-799.[31]Yavari SA,Wauthle R,van der Stok J,et al.Fatigue behavior of porous biomaterials manufactured using selectivelaser melting.Mater Sci Eng C Mater Biol Appl. 2013;33(8):4849-4858.[32]Otsuki B,Takemoto M,Fujibayashi S,et al.Pore throat size and connectivity determine bone and tissue ingrowthinto porous implants: Three-dimensional micro-CT based structuralanalyses of porous bioactive titanium implants. Biomaterials. 2006;27(35):5892-5900.[33]Gómez S,Vlad MD,López J,et al.Design and properties of 3D scaffolds for bone tissue engineering.Acta Biomater. 2016.pii: S1742-7061(16)30309-9.[34]Marin E,Fusi S,Pressacco M,et al.Characterization of cellular solids in Ti6Al4V for orthopaedicimplant applications: Trabeculartitanium.J Mech Behav Biomed Mater. 2010;3(5):373-381. [35]Parthasarathy J,Starly B,Raman S,et al.Mechanical evaluation of porous titanium (Ti6Al4V)structures with electron beam melting (EBM).J Mech Behav Biomed Mater.2010;3(3):249-259.[36]Van Bael S,Chai YC,Truscello S,et al.The effect of pore geometry on the in vitro biological behavior of humanperiosteum-derived cells seeded on selective laser-melted Ti6Al4V bone scaffolds.Acta Biomater. 2012;8(7):2824-2834.[37]Di Luca A,Lorenzo-Moldero I,Mota C,et al. Osteochondral Regeneration: Tuning Cell Differentiation into a 3D Scaffold Presenting a Pore Shape Gradient for Osteochondral Regeneration.Adv Healthc Mater.2016;5(14):1832. [38]Liang Y,Li H,Xu J,et al.Morphology, Composition, and Bioactivity of Strontium-Doped Brushite Coatings Deposited on Titanium Implants via Electrochemical Deposition. Int J Mol Sci.2014;15(6):9952-9962.[39]Medvedev AE,Ng HP,Lapovok R,et al.Effect of bulk microstructure of commercially pure titanium on surface characteristics and fatigue properties after surface modification by sand blasting and acid-etching. J Mech Behav Biomed Mater. 2015;57:55-68. [40]Heinl P,Müller L,Körner C,et al.Cellular Ti–6Al–4V structures with interconnected macro porosity for bone implants fabricated by selective electron beam melting. Acta Biomaterialia.2008;4(5):1536-1544.[41]Le VQ,Pourroy G,Cochis A,et al.Alternative technique for calcium phosphate coating on titanium alloy implants. Biomatter.2014;4:e28534.[42]Amin Yavari S,van der Stok J,Chai YC,et al.Bone regeneration performance of surface-treated porous titanium.Biomaterials.2014;35(24):6172-6181. |

.jpg)

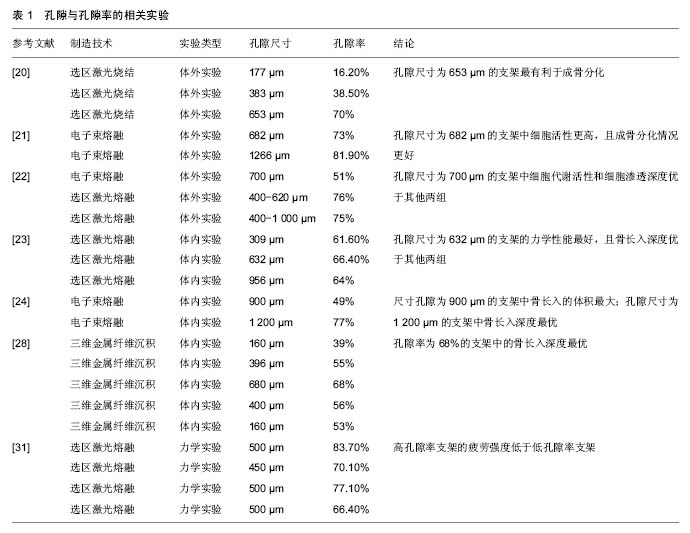

.jpg)