[1] VIRANI SS, ALONSO A, BENJAMIN EJ, et al. Heart disease and stroke statistics-2020 update: a report from the American Heart Association. Circulation. 2020;141(9): E139-E596.

[2] JEREMIAS A, KAUL S, ROSENGART TK, et al. The impact of revascularization on mortality in patients with nonacute coronary artery disease. Am J Med. 2009; 122(2):152-161.

[3] KIESER TM, LEWIN AM, GRAHAM MM, et al. Outcomes associated with bilateral internal thoracic artery grafting: the importance of age. Ann Thorac Sugr. 2011; 92(4):1269-1275.

[4] ZHU AP, MING Z, JIAN S. Blood compatibility of chitosan/heparin complex surface modified ePTFE vascular graft. Appl Surf Sci. 2005;241(3-4):485-492.

[5] LI J, LIN F, LI LD, et al. Surface engineering of poly(ethylene terephthalate) for durable hemocompatibility via a surface interpenetrating network technique. Macromol Chem Phys. 2012; 213(20):2120-2129.

[6] SHIN YM, LEE YB, KIM SJ, et al. Mussel-inspired immobilization of vascular endothelial growth factor (VEGF) for enhanced endothelialization of vascular grafts. Biomacromolecules. 2012;13(7):2020-2028.

[7] FINK H, HONG J, DROTZ K, et al. An in vitro study of blood compatibility of vascular grafts made of bacterial cellulose in comparison with conventionally-used graft materials. J Biomed Mater Res Part A. 2011;97A(1):52-58.

[8] LI X, TANG JY, BAO LH, et al. Performance improvements of the BNC tubes from unique double-silicone-tube bioreactors by introducing chitosan and heparin for application as small-diameter artificial blood vessels. Carbohydr Polym. 2017; 178:394-405.

[9] FINK H, FAXALV L, MOLNAR GF, et al. Real-time measurements of coagulation on bacterial cellulose and conventional vascular graft materials. Acta Biomater. 2010;6(3):1125-1130.

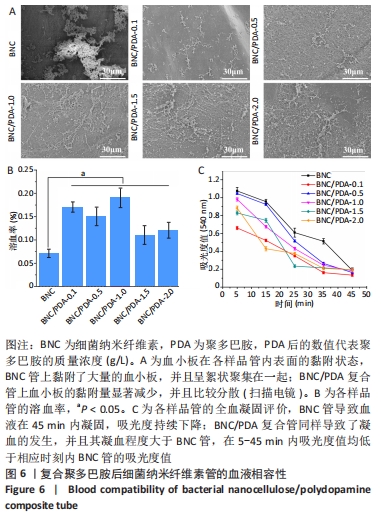

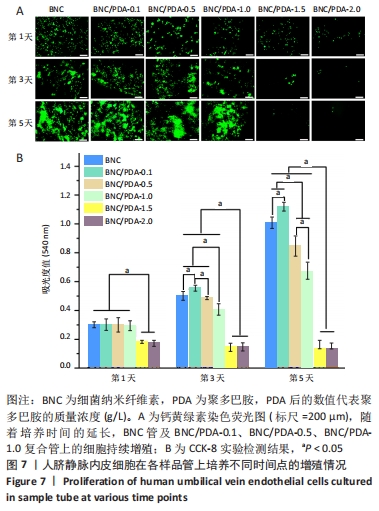

[10] LAI C, ZHANG SJ, SHENG LY, et al. Comparative evaluation of the biocompatible and physical-chemical properties of poly(lactide-co-glycolide) and polydopamine as coating materials for bacterial cellulose. J Mat Chem B. 2019;7(4):630-639.

[11] PERTILE R, MOREIRA S, ANDRADE F, et al. Bacterial cellulose modified using recombinant proteins to improve neuronal and mesenchymal cell adhesion. Biotechnol Progr. 2012;28(2):526-532.

[12] FINK H, AHRENSTEDT L, BODIN A, et al. Bacterial cellulose modified with xyloglucan bearing the adhesion peptide RGD promotes endothelial cell adhesion and metabolism - a promising modification for vascular grafts. J Tissue Eng Regen Med. 2011;5(6):454-463.

[13] LEE H, DELLATORE SM, MILLER WM, et al. Mussel-inspired surface chemistry for multifunctional coatings. Science (New York, NY). 2007;318(5849):426-430.

[14] LUO RF, TANG LL, WANG J, et al. Improved immobilization of biomolecules to quinone-rich polydopamine for efficient surface functionalization. Colloid Suraface B. 2013;106:66-73.

[15] KU SH, PARK CB. Human endothelial cell growth on mussel-inspired nanofiber scaffold for vascular tissue engineering. Biomaterials. 2010;31(36):9431-9437.

[16] DAVOUDI P, ASSADPOUR S, DERAKHSHAN MA, et al. Biomimetic modification of polyurethane-based nanofibrous vascular grafts: A promising approach towards stable endothelial lining. Mat Sci Eng C-Mater. 2017;80:213-221.

[17] YANG ZL, TU QF, ZHU Y, et al. Mussel-inspired coating of polydopamine directs endothelial and smooth muscle cell fate for re-endothelialization of vascular devices. Adv Healthc Mater. 2012;1(5):548-559.

[18] OBIWELUOZOR FO, TIWARI AP, LEE JH, et al. Thromboresistant semi-IPN hydrogel coating: towards improvement of the hemocompatibility/biocompatibility of metallic stent implants. Mater Sci Eng C-Mater Biol Appl. 2019;99:1274-1288.

[19] HUANG Y, ZHAO X, ZHANG Z, et al. Degradable gelatin-based IPN cryogel hemostat for rapidly stopping deep noncompressible hemorrhage and simultaneously improving wound healing. Chem Mater. 2020;32(15):6595-6610.

[20] 唐文婷.基于聚多巴胺纳米材料的制备及在肿瘤微波热疗中的应用[D].北京:北京交通大学,2016.

[21] JIANG QS, DERAMI HG, GHIM D, et al. Polydopamine-filled bacterial nanocellulose as a biodegradable interfacial photothermal evaporator for highly efficient solar steam generation. J Mater Chem A. 2017;5(35):18397-18402.

[22] YANG LY, CHEN CT, HU Y, et al. Three-dimensional bacterial cellulose/polydopamine/TiO2 nanocomposite membrane with enhanced adsorption and photocatalytic degradation for dyes under ultraviolet-visible irradiation. J Colloid Interface Sci. 2020;562:21-28.

[23] XIE YJ, YUE LN, ZHENG YD, et al. The antibacterial stability of poly(dopamine) in-situ reduction and chelation nano-Ag based on bacterial cellulose network template . Appl Surf Sci. 2019;491;383-394.

[24] BAO LH, TANG JY, HONG FF, et al. Physicochemical properties and in vitro biocompatibility of three bacterial nanocellulose conduits for blood vessel applications. Carbohydr Polym. 2020;239:13.

[25] 申芳瑜.用于血管介入器械表面改性的铜介导原位催化产生一氧化氮涂层的构建[D].成都:西南交通大学,2016.

[26] 段传双,包露涵,陈琳,等.细菌纳米纤维素/聚乙烯醇小径人工血管的制备及其表征[J].纤维素科学与技术,2020,28(2):1-10.

[27] 姚艳.应用于组织工程血管支架的纯镁的表面改性及性能研究[D].重庆:重庆大学,2018.

[28] 唐敬玉,包露涵,李雪,等.细菌纳米纤维素与聚乙烯醇复合水凝胶管的生物相容性表征[J].中国组织工程研究,2017,21(34): 5474-5480.

[29] 曹海建,钱坤.人造血管的现状及其研究进展[J].四川纺织科技,2004(2):31-33.

[30] KONIG G, MCALLISTER TN, DUSSERRE N, et al. Mechanical properties of completely autologous human tissue engineered blood vessels compared to human saphenous vein and mammary artery. Biomaterials. 2009;30(8):1542-1550.

[31] DOBROVOLSKAIA MA, CLOGSTON JD, NEUN BW, et al. Method for analysis of nanoparticle hemolytic properties in vitro. Nano Lett. 2011;8(8):2180-2187.

[32] YANG XL, LIU X, WU QQ, et al. Dopamine-assisted immobilization of peptide arginine-glycine-aspartic acid to enhance the cellular performances of MC3T3-E1 cells of carbon-carbon composites. J Biomater Appl. 2019;34(2):284-296.

[33] WEI Q, LI BJ, YI N, et al. Improving the blood compatibility of material surfaces via biomolecule-immobilized mussel-inspired coatings. J Biomed Mater Res Part A. 2011;96A(1):38-45.

[34] LEITAO AF, GUPTA S, SILVA JP, et al. Hemocompatibility study of a bacterial cellulose/polyvinyl alcohol nanocomposite. Colloids Surf B. 2013;111:493-502.

[35] YANG Y, QI PK, DING YH, et al. A biocompatible and functional adhesive amine-rich coating based on dopamine polymerization. J Mat Chem B. 2015;3(1): 72-81.

|