| [1]Goudie EB, Robinson C, Walmsley P, et al. Changing trends in total knee replacement. Eur J Orthop Surg Traumatol. 2017;27(4):539-544.[2]Nam D, Mcarthur BA, Cross MB, et al. Patient-specific instrumentation in total knee arthroplasty: a review. J Knee Surg. 2012;25(3):213-220.[3]Noble PC, Conditt MA, Cook KF, et al. The John Insall Award: Patient expectations affect satisfaction with total knee arthroplasty. Clin Orthop Relat Res. 2006;452(452):35-43.[4]Massin P. How does total knee replacement technique influence polyethylene wear. Orthop Traumatol Surg Res. 2017; 103(1):S21.[5]Werner FW, Ayers DC, Maletsky LP, et al. The effect of valgus/varus malalignment on load distribution in total knee replacements. J Biomech. 2005;38(2):349-355.[6]Martinelli N, Baretta S, Pagano J, et al. Contact stresses, pressure and area in a fixed-bearing total ankle replacement: a finite element analysis. BMC Musculoskeletal Disorders. 2017;18(3):2473011417S0002.[7]Cerquiglini A, Henckel J, Hothi HS, et al. Computed tomography techniques help understand wear patterns in retrieved total knee arthroplasty. J Arthroplasty. 2018;33(9):3030-3037.[8]Villa TMF, Gastaldi D, Colombo M, et al. Contact stresses and fatigue life in a knee prosthesis: comparison between in vitro measurements and computational simulations. J Biomech. 2004;37(1):45-53.[9]Goswami T. Knee implants-Review of models and biomechanics. Mater Des. 2009;30(2):398-413.[10]Bartel DL, Rawlinson JJ, Burstein AH, et al. Stresses in polyethylene components of contemporary total knee replacements. Clin Orthop Relat Res. 1995;317(317):76-82.[11]Collier JP, Mayor MB, Mcnamara JL, et al. Analysis of the Failure of 122 Polyethylene Inserts From Uncemented Tibial Knee Components. Clin Orthop Relat Res. 1991;273(273):232-242.[12]Stukenborgcolsman C, Ostermeier S, Hurschler C, et al. Tibiofemoral contact stress after total knee arthroplasty: comparison of fixed and mobile-bearing inlay designs. Acta Orthopaedica Scandinavica. 2002; 73(6):638-646.[13]Sathasivam S, Walker PS. Computer model to predict subsurface damage in tibial inserts of total knees. J Orthop Res. 2010;16(5):564.[14]莫富灏,杜敏,刘傥,等. 肿瘤型膝关节置换后股骨-假体-胫骨复合体生物力学响应[J]. 医用生物力学,2016,31(3):235-239.[15]Woiczinski M, Steinbrück A, Weber P, et al. Development and validation of a weight-bearing finite element model for total knee replacement. Comput Methods Biomech Biomed Engin. 2016;19(10): 1033-1045. [16]Nakamura S , Tian Y , Tanaka Y , et al. The effects of kinematically aligned total knee arthroplasty on stress at the medial tibia. Bone Joint Res. 2017;6(1):43-51.[17]Young SW, Koh CK, Ravi S, et al. Total knee arthroplasty in the 21st century: why do they fail? a fifteen-year analysis of 11, 135 knees. Orthop J Sports Med. 2017;5(5 suppl5):2325967117S0020.[18]Barbour PS, Barton DC, Fisher J. The influence of stress conditions on the wear of UHMWPE for total joint replacements. J Mater Sci Mater Med. 1997;8(10):603.[19]郭媛,张绪树,安美文,等. 日常运动时内翻人工膝关节接触压力的有限元分析[J]. 太原理工大学学报,2014,45(3):358-362.[20]Shi JF. Finite element analysis of total knee replacement considering gait cycle load and malalignment. Quaternary Sci. 2007;27(5): 870-879.[21]Li X, Wang C, Guo Y, et al. An approach to developing customized total knee replacement implants. J Health Eng. 2017; 2017(8):1-8.[22]Munzinger UK , Wyss U , Boldt JG , et al. Basic Science, Design, and Materials[M]// Primary Knee Arthroplasty. Springer Berlin Heidelberg, 2004.[23]Teo A, Mishra A, Park I, et al. Polymeric Biomaterials for Medical Implants & Devices. Acs Biomat Sci Eng. 2016; 2(4): 454-472.[24]张绪树,郭媛,安美文,等. 不同运动状态下国产人工膝关节接触压力分布有限元分析[J]. 计算机辅助工程,2013,22(2):61-65.[25]Halloran JP, Petrella AJ, Rullkoetter PJ. Explicit finite element modeling of total knee replacement mechanics. J Biomech. 2005; 38(2):323-331.[26]李新宇,王长江,陈维毅. 一种新型膝关节假体在步态过程中接触应力的有限元仿真[J]. 医用生物力学,2017,32(6):494-499.[27]崔晓倩,王辅忠,张慧春. 膝关节股骨远端软骨硬化前后力学性能分析[J]. 医用生物力学,2015,30(1):25-29.[28]Crowninshield R, Pope MH, Johnson RJ. An analytical model of the knee. J Biomech. 1976;9(6):397-405.[29]王俊然,杜玮瑾,王长江,等. 有限元分析不同屈曲状态下胫-股关节的生物力学变化[J]. 中国组织工程研究,2018,22(31):4975-4981.[30]Taylor M, Barrett DS. Explicit finite element simulation of eccentric loading in total knee replacement. Clin Orthop Relat Res. 2003;414 (414):162-171.[31]ISO, ISO 14243-3: 2014, Implants for Surgery-Wear of Total Knee-Joint Prostheses, Loading and Displacement Parameters for Wear-Testing Machines with Displacement Control and Corresponding Environmental Conditions for Test, International Organization Environmental Standardization, London, UK, 2014.[32]Lafortune MA, Cavanagh PR, Iii HJS, et al. Three-dimensional kinematics of the human knee during walking. J Biomech. 1992;25(4): 347-357.[33]Gruionu LG, Gruionu G, Pastrama S, et al. Contact studies between total knee replacement components developed using explicit finite elements analysis.[C]// International Conference on Medical Image Computing & Computer-assisted Intervention. 2009.[34]赵奇,蒋垚. 人工膝关节假体设计新进展[J]. 中国组织工程研究,2010, 14(52):9838-9840.[35]邓海宁,曹轲飞,蒋仕雄. 全膝关节置换术假体的三维有限元生物力学分析[J]. 基因组学与应用生物学,2017,36(12):4992-4999.[36]Nguyen LCL, Lehil MS, Bozic KJ. Trends in total knee arthroplasty implant utilization. J Arthroplasty. 2015;30(5):739-742.[37]Nakamura S, Tian Y, Tanaka Y, et al. The effects of kinematically aligned total knee arthroplasty on stress at the medial tibia:A case study for varus knee. Bone Joint Res. 2017;6(1):43-51.[38]Vince KG. Why knees fail. J Arthroplasty. 2003;18(1):39-44.[39]Brockett C, Carbone S, Fisher J, et al. Influence of conformity on the wear of total knee replacement: An experimental study. Proc Inst Mech Eng H. 2018;232(2):127-134. [40]D'Lima DD, Chen PC, Jr CC. Polyethylene contact stresses, articular congruity, and knee alignment. Clin Orthop Relat Res. 2001;392(392): 232-238.[41]Rivière C, Iranpour F, Auvinet E, et al. Alignment options for total knee arthroplasty: A systematic review. Orthop Traumatol Surg Res. 2017; 103(7):1047.[42]Affatato S, Valigi MC, Logozzo S. Wear distribution detection of knee joint prostheses by means of 3d optical scanners. Materials. 2017;10(4):36.[43]Tarni?? D, Calafeteanu DM, Geonea ID, et al. Effects of malalignment angle on the contact stress of knee prosthesis components, using finite element method. Rom J Morphol Embryol. 2017;58(3):831-836. [44]Brockett CL, Abdelgaied A, Haythornthwaite T, et al. The influence of simulator input conditions on the wear of total knee replacements: An experimental and computational study. Proc Inst Mech Eng H. 2016; 230(5):429-439. |

.jpg) 文题释义:

文题释义:

.jpg) 文题释义:

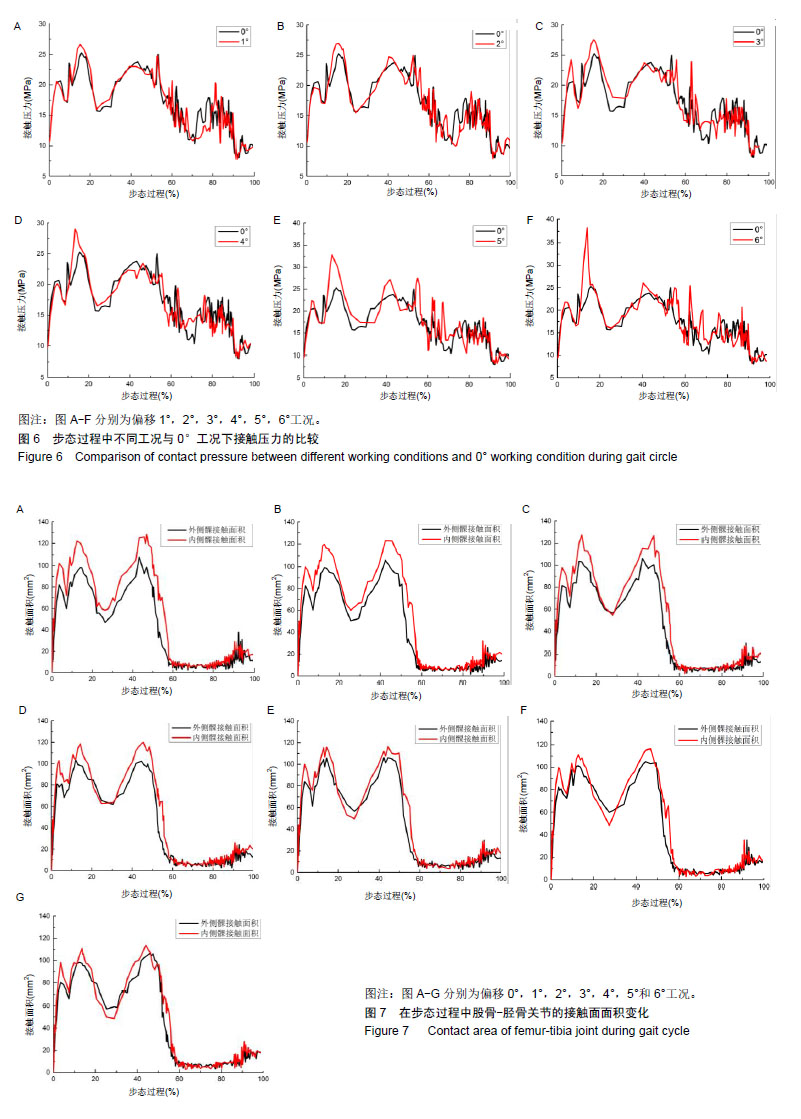

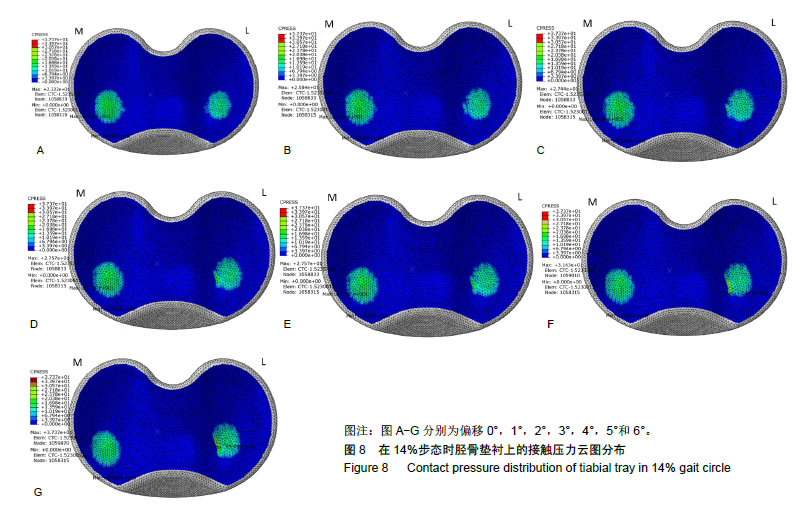

文题释义: