| [1] CHARNLEY J.Anchorage of the femoral head prosthesis to the shaft of the femur. J Bone Joint Surg Br.1960;42-B:28-30.[2] Mahon OR,O'Hanlon S,Cunningham CC,et al.Orthopaedic implant materials drive M1 macrophage polarization in a spleen tyrosine kinase- and mitogen-activated protein kinase-dependent manner. Acta Biomater.2018;65:426-435.[3] Gao X,Ge J,Li W,et al. LncRNA KCNQ1OT1 ameliorates particle-induced osteolysis through inducing macrophage polarization by inhibiting miR-21a-5p.Biol Chem. 2018; 399(4): 375-386.[4] Antonios JK,Yao Z,Li C,et al. Macrophage polarization in response to wear particles in vitro. Cell Mol Immunol. 2013;10(6): 471-482. [5] Kim W,Yoon PW,Kwak HS,et al.Primary hybrid THA using a polymethyl methacrylate-precoated stem: A single-center experience with a 10-year minimum follow-up. J Biomed Mater Res B Appl Biomater. 2017;105(5):1300-1306.[6] Ayre WN,Denyer SP,Evans SL.Ageing and moisture uptake in polymethyl methacrylate (PMMA) bone cements.J Mech Behav Biomed Mater.2014;32:76-88. [7] Dall'Oca C,Maluta T,Cavani F,et al. The biocompatibility of porous vs non-porous bone cements: a new methodological approach. Eur J Histochem.2014;58(2):2255. [8] Yang J,Zhang K,Zhang S,et al.Preparation of calcium phosphate cement and polymethyl methacrylate for biological composite bone cements.Med Sci Monit.2015;21:1162-1172.[9] Lye KW,Tideman H,Wolke JC,et al.Biocompatibility and bone formation with porous modified PMMA in normal and irradiated mandibular tissue.Clin Oral Implants Res.2013;24 Suppl A 100: 100-109.[10] Sa Y,Yu N,Wolke JGC,et al.Bone Response to Porous Poly(methyl methacrylate) Cement Loaded with Hydroxyapatite Particles in a Rabbit Mandibular Model.Tissue Eng Part C Methods.2017;23(5):262-273.[11] Sa Y, Yang F,de Wijn JR, et al. Physicochemical properties and mineralization assessment of porous polymethylmethacrylate cement loaded with hydroxyapatite in simulated body fluid. Mater Sci Eng C Mater Biol Appl. 2016;61:190-198. [12] Wang L,Yoon DM,Spicer PP,et al.Characterization of porous polymethylmethacrylate space maintainers for craniofacial reconstruction.J Biomed Mater Res B Appl Biomater. 2013;101(5): 813-825.[13] Lewis G. Properties of acrylic bone cement: state of the art review. J Biomed Mater Res. 1997;38(2):155-182.[14] 张森林.磷酸钙骨水泥的研究进展[J].医学研究生学报, 2003,16(1): 62-63. [15] 陈浩东,姚金凤,梁志刚.磷酸钙的固有骨诱导性及其应用[J].中国组织工程研究,2016,20(25):3785-3792. [16] Li Y,Jiang T,Zheng L,et al.Osteogenic differentiation of mesenchymal stem cells (MSCs) induced by three calcium phosphate ceramic (CaP) powders: A comparative study.Mater Sci Eng C Mater Biol Appl. 2017;80:296-300. [17] 尚希福,汤亭亭,戴尅戎.TCP-PMMA骨水泥-骨界面强度变化的研究[J].医用生物力学,2006,21(2):111-114. [18] Liu Z, Tang Y, Kang T, et al. Synergistic effect of HA and BMP-2 mimicking peptide on the bioactivity of HA/PMMA bone cement.Colloids Surf B Biointerfaces.2015;131:39-46. [19] Lewis G.Properties of nanofiller-loaded poly (methyl methacrylate) bone cement composites for orthopedic applications: a review.J Biomed Mater Res B Appl Biomater. 2017;105(5):1260-1284. [20] Wolf-Brandstetter C,Roessler S,Storch S,et al.Physicochemical and cell biological characterization of PMMA bone cements modified with additives to increase bioactivity. J Biomed Mater Res B Appl Biomater. 2013;101(4):599-609[21] Klaus-DieterKuhn.PMMA骨水泥[M].张克,吕维加译.北京:北京大学医学出版社,2015.[22] 行业标准YY0459-2003/ISO5833:2002丙烯酸类树脂骨水泥:国家食品药品监督管理局,2013.[23] ISO 10993-11:1994 , Biological evaluation of medical devices-Part 11:Tests for systemic toxicity.2003.[24] Langer R,Vacanti JP.Tissue engineering. Science. 1993;260 (5110):920-926. [25] Fottner A,Nies B,Kitanovic D,et al.Performance of bioactive PMMA-based bone cement under load-bearing conditions: an in vivo evaluation and FE simulation. J Mater Sci Mater Med. 2016; 27(9):138.[26] Verburg H, van de Ridder LC, Verhoeven VW, et al. Validation of a measuring technique with computed tomography for cement penetration into trabecular bone underneath the tibial tray in total knee arthroplasty on a cadaver model. BMC Med Imaging 2014; 14:29. [27] Van Susante JLC,Verdonschot N,Bom LPA,et al.Lessons learnt from early failure of a patient trial with a polymer-on-polymer resurfacing hip arthroplasty.Acta Orthop. 2018;89(1):59-65.[28] Chen C,Li D,Wang Z,et al.Safety and Efficacy Studies of Vertebroplasty, Kyphoplasty, and Mesh-Container-Plasty for the Treatment of Vertebral Compression Fractures: Preliminary Report. PLoS One.2016;11(3):e0151492. [29] Wang H,Sribastav SS,Ye F,et al.Comparison of Percutaneous Vertebroplasty and Balloon Kyphoplasty for the Treatment of Single Level Vertebral Compression Fractures: A Meta-analysis of the Literature. Pain Physician. 2015;18(3):209-222.[30] Chandra W,Prasad BC,Jagadeesh MA,et al.Segmental polymethylmethacrylate-augmented fenestrated pedicle screw fixation for lumbar spondylolisthesis in patients with osteoporosis - A case series and review of literature.Neurol India. 2017;65(1): 89-95. [31] Kim JG,Jin YJ,Chung SK,et al.Unilateral augmented pedicle screw fixation for foraminal stenosis. J Korean Neurosurg Soc. 2009;46(1):5-10. [32] Yimin Y,Zhiwei R,Wei M,et al.Current status of percutaneous vertebroplasty and percutaneous kyphoplasty--a review.Med Sci Monit.2013;19:826-836. [33] Wegener B,Zolyniak N,Gülecyüz MF,et al. Heat distribution of polymerisation temperature of bone cement on the spinal canal during vertebroplasty.Int Orthop.2012;36(5):1025-1030.[34] McMahon S,Hawdon G,Baré J,et al.In vivo response of bone defects filled with PMMA in an ovine model.Hip Int. 2011;21(5): 616-622. [35] Xu HH,Burguera EF,Carey LE.Strong, macroporous, and in situ-setting calcium phosphate cement-layered structures. Biomaterials.2007;28(26):3786-3796. [36] Tsuruga E,Takita H,Itoh H,et al.Pore size of porous hydroxyapatite as the cell-substratum controls BMP-induced osteogenesis.J Biochem.1997;121(2):317-324. [37] Moreau MF,Chappard D,Lesourd M,et al.Free radicals and side products released during methylmethacrylate polymerization are cytotoxic for osteoblastic cells.J Biomed Mater Res. 1998;40(1): 124-131.[38] Bettencourt A,Calado A,Amaral J, et al.In vitro release studies of methylmethacrylate liberation from acrylic cement powder. Int J Pharm.2000;197(1-2):161-168. [39] Hoess A,López A,Engqvist H, et al.Comparison of a quasi-dynamic and a static extraction method for the cytotoxic evaluation of acrylic bone cements. Mater Sci Eng C Mater Biol Appl.2016;62:274-282.[40] 郭新辉,吕扬阳,范积平,等.磷酸钙与聚甲基丙烯酸甲酯制备复合型骨水泥的生物安全性研究[J].中国骨与关节损伤杂志, 2016,31(5): 506-510. |

.jpg)

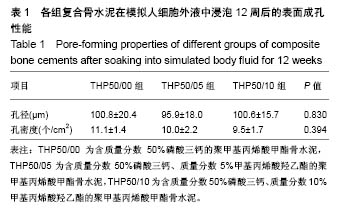

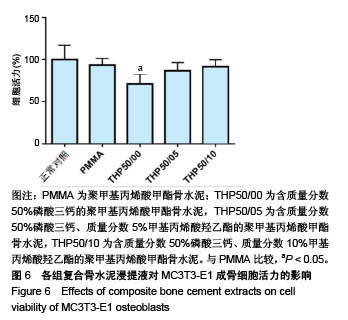

.jpg)