| [1] 刘昌胜.硬组织修复材料与技术[M].北京:科学出版社,2014.[2] 王成健.多孔SrO/HA生物复合陶瓷骨修复材料的制备及体外生物相容性研究[D].昆明:昆明理工大学硕士学位论文,2016.[3] Van der Stok J, Van Lieshout EM, El-Massoudi Y, et al. Bone substitutes in the Netherlands - a systematic literature review. Acta Biomater. 2011;7(2):739-750. [4] Kolk A, Handschel J, Drescher W, et al. Current trends and future perspectives of bone substitute materials - from space holders to innovative biomaterials. J Craniomaxillofac Surg. 2012;40(8):706-718. [5] Bouler JM, Pilet P, Gauthier O, et al. Biphasic calcium phosphate ceramics for bone reconstruction: A review of biological response. Acta Biomater. 2017;53:1-12. [6] Li J, Baker BA, Mou X, et al. Biopolymer/Calcium phosphate scaffolds for bone tissue engineering. Adv Healthc Mater. 2014;3(4):469-484.[7] Ben-Nissan B. Advances in Calcium Phosphate Biomaterials. Springer. 2014.[8] Ginebra MP, Espanol M, Montufar EB, et al. New processing approaches in calcium phosphate cements and their applications in regenerative medicine. Acta Biomater. 2010;6(8):2863-2873. [9] Krüger R, Groll J. Fiber reinforced calcium phosphate cements -- on the way to degradable load bearing bone substitutes? Biomaterials. 2012;33(25):5887-5900.[10] Nezafati N, Moztarzadeh F, Hesaraki S, et al. Biological response of a recently developed nanocomposite based on calcium phosphate cement and sol-gel derived bioactive glass fibers as substitution of bone tissues. Ceram Int 2013;39(2):289-297.[11] Zhang J, Liu W, Schnitzler V, et al. Calcium phosphate cements for bone substitution: chemistry, handling and mechanical properties. Acta Biomater. 2014;10(3):1035-1049. [12] Comuzzi L, Ooms E, Jansen JA. Injectable calcium phosphate cement as a filler for bone defects around oral implants: an experimental study in goats. Clin Oral Implants Res. 2002;13(3):304-311.[13] Vater C, Lode A, Bernhardt A, et al. Influence of different modifications of a calcium phosphate bone cement on adhesion, proliferation, and osteogenic differentiation of human bone marrow stromal cells. J Biomed Mater Res A. 2010;92(4):1452-1460. [14] Farrar DF. Bone adhesives for trauma surgery: A review of challenges and developments. Int J Adhes Adhes. 2012;33(3):89-97.[15] Ostrowski N, Roy A, Kumta PN. Magnesium Phosphate Cement Systems for Hard Tissue Applications: A Review. ACS Biomater Sci Eng. 2016;2(7):1067-1083.[16] Tamimi F, Le Nihouannen D, Bassett DC, et al. Biocompatibility of magnesium phosphate minerals and their stability under physiological conditions. Acta Biomater. 2011;7(6):2678-2685. [17] Pina S, Ferreira JMF. Brushite-forming Mg-, Zn- and Sr-substituted bone cements for clinical applications. Materials. 2010;3(1):519-535.[18] Ostrowski N, Lee B, Hong D, et al. Synthesis, osteoblast, and osteoclast viability of amorphous and crystalline tri-magnesium phosphate. ACS Biomater Sci Eng. 2015;1(1):52-63.[19] Driessens FCM, Boltong MG, Zapatero MI, et al. In vivo behaviour of three calcium phosphate cements and a magnesium phosphate cement. J Mater Sci Mater Med. 1995;6(5):272-278.[20] Liu C. Inorganic bone adhesion agent and its use in human hard tissue repair: US, 7094286. 2006-08-22.[21] Waselau M, Samii VF, Weisbrode SE, et al. Effects of a magnesium adhesive cement on bone stability and healing following a metatarsal osteotomy in horses. Am J Vet Res. 2007;68(4):370-378.[22] Gulotta LV, Kovacevic D, Ying L, et al. Augmentation of tendon-to-bone healing with a magnesium-based bone adhesive. Am J Sports Med. 2008;36(7):1290-1297. [23] Li Y, Chen B. Factors that affect the properties of magnesium phosphate cement. Constr Build Mater. 2013;47:977-983.[24] Mestres G, Abdolhosseini M, Bowles W, et al. Antimicrobial properties and dentin bonding strength of magnesium phosphate cements. Acta Biomater. 2013;9(9):8384-8393. [25] Yu Y, Wang J, Liu C, et al. Evaluation of inherent toxicology and biocompatibility of magnesium phosphate bone cement. Colloids Surf B Biointerfaces. 2010;76(2):496-504. [26] Wu F, Wei J, Guo H, et al. Self-setting bioactive calcium-magnesium phosphate cement with high strength and degradability for bone regeneration. Acta Biomater. 2008;4(6):1873-1884. [27] Yang G, Liu J, Li F, et al. Bioactive calcium sulfate/magnesium phosphate cement for bone substitute applications. Mater Sci Eng C Mater Biol Appl. 2014;35:70-76. [28] Mestres G, Ginebra MP. Novel magnesium phosphate cements with high early strength and antibacterial properties. Acta Biomater. 2011; 7(4):1853-1861. [29] Zhou H, Agarwal AK, Goel VK, et al. Microwave assisted preparation of magnesium phosphate cement (MPC) for orthopedic applications: a novel solution to the exothermicity problem. Mater Sci Eng C Mater Biol Appl. 2013;33(7):4288-4294. [30] Wang AJ, Zhang J, Li JM, et al. Effect of liquid-to-solid ratios on the properties of magnesium phosphate chemically bonded ceramics. Mater Sci Eng C Mater Biol Appl. 2013;33(5):2508-2512. [31] Wang AJ, Fan XJ, Li JM, et al. Curing Behavior and Structure of Magnesium Phosphate Chemically Bonded Ceramics with Different MgO to KH2PO4 Ratios. Int J Appl Ceram Technol. 2015;12(6): 1124-1130.[32] Inzana JA, Olvera D, Fuller SM, et al. 3D printing of composite calcium phosphate and collagen scaffolds for bone regeneration. Biomaterials. 2014;35(13):4026-4034.[33] Villa MM, Wang L, Huang J, et al. Bone tissue engineering with a collagen-hydroxyapatite scaffold and culture expanded bone marrow stromal cells. J Biomed Mater Res B Appl Biomater. 2015;103(2):243-253. [34] Sarker B, Hum J, Nazhat SN, et al. Combining collagen and bioactive glasses for bone tissue engineering: a review. Adv Healthc Mater. 2015;4(2):176-194. [35] 陈俊德,易瑞灶,陈晖.鱼胶原蛋白及其活性肽的研究进展[J].中国海洋药物杂志,2009,8(4):52-56.[36] 张兵,王毅虎,王富荣,等.浅谈胶原蛋白水解物对于人关节软骨的作用[J].明胶科学与技术,2015,35(1):44-46.[37] 蒋建新,张先龙,金东旭,等.服用胶原蛋白多肽对中老年女性膝骨关节炎患者关节疼痛和功能的临床效果研究[J].中国骨质疏松杂志, 2013,19(11): 1184-1186,1199.[38] Liu J, Zhang B, Song S, et al. Bovine collagen peptides compounds promote the proliferation and differentiation of MC3T3-E1 pre-osteoblasts. PLoS One. 2014;9(6):e99920. [39] ASTM C266-99. Standard test method for time of setting of hydraulic-cement paste by gillmore needles. PA, USA: ASTM International. 1999.[40] Lee J, Farag MM, Park EK, et al. A simultaneous process of 3D magnesium phosphate scaffold fabrication and bioactive substance loading for hard tissue regeneration. Mater Sci Eng C Mater Biol Appl. 2014;36:252-260. [41] Wu X, Tao Y, Song C, et al. Morphological control and luminescent properties of YVO4:Eu nanocrystals. J Phys Chem B. 2006;110(32): 15791-15796.[42] 曹霄峰,张雷,马英丽,等.Zn3(OH)2V2O7•2H2O 纳米片的水热制备[J].无机化学学报,2010,26(5):787-792.[43] 杨伟,袁芳,高彦祥.鱼胶原蛋白肽与表没食子儿茶素没食子酸酯相互作用的研究[J].光谱学与光谱分析,2015,35(1):184-188.[44] 张秉文.磷酸镁骨粘合剂的生物安全性研究[D].上海:复旦大学, 2010.[45] Soudée E, Péra J. Mechanism of setting reaction in magnesia-phosphate cements. Cem Concr Res. 2000;30(2):315-321.[46] Qiao F, Chau CK, Li ZJ. Calorimetric study of magnesium potassium phosphate cement. Mater Struc. 2012;45(3):447-456.[47] Wang AJ, Yuan ZL, Zhang J, et al. Effect of raw material ratios on the compressive strength of magnesium potassium phosphate chemically bonded ceramics. Mater Sci Eng C Mater Biol Appl. 2013;33(8): 5058-5063. [48] Wang CW, Chiang TY, Chang HC, et al. Physicochemical properties and osteogenic activity of radiopaque calcium silicate-gelatin cements. J Mater Sci Mater Med. 2014;25(9):2193-2203. [49] Babaie E, Lin B, Goel VK, et al. Evaluation of amorphous magnesium phosphate (AMP) based non-exothermic orthopedic cements. Biomed Mater. 2016;11(5):055010.[50] Samali A, Holmberg CI, Sistonen L, et al. Thermotolerance and cell death are distinct cellular responses to stress: dependence on heat shock proteins. FEBS Lett. 1999;461(3):306-310. |

.jpg)

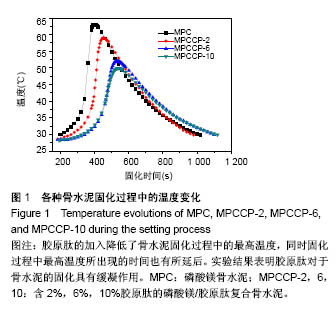

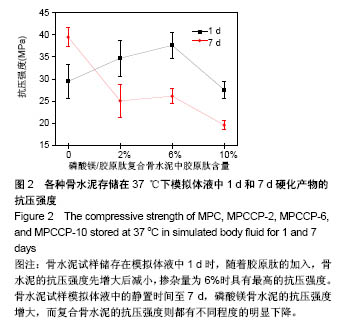

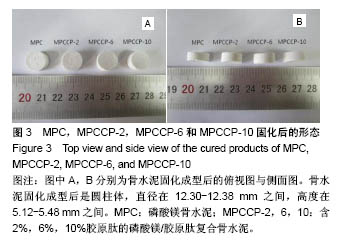

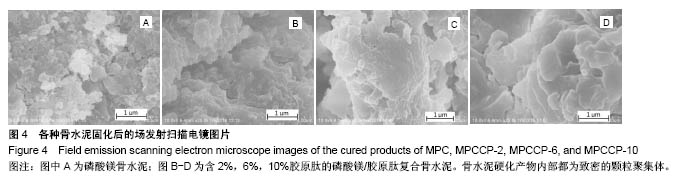

.jpg)