| [1] 俞能宝,董天华,孙俊英.复合材料股骨头假体三维有限元分析[J].医用生物力学,2001,16(3):155-159.[2] Wallis JA, Taylor NF. Pre-operative interventions (non-surgical and non-pharmacological) for patients with hip or knee osteoarthritis awaiting joint replacement surgery--a systematic review and meta-analysis. Osteoarthritis Cartilage. 2011;19(12):1381-1395.[3] 白艳杰.钛铌合金生物相容性评价与植入实验研究[D].重庆:重庆医科大学,2012.[4] 吕厚山.人工关节的新进展[J].首都医药,2001,8(4):36-38.[5] Martin Ihle, Sabine Mai, Werner E.Siebert,等.陶瓷球头和金属球头配伍聚乙烯臼杯的20年长期对比磨损研究[J].中华关节外科杂志(电子版),2010,4(3):392-396.[6] Zimmerma S, Hawkes WG, Hudson JI, et al. Outcomes of surgical management of total HIP replacement in patients aged 65 years and older: cemented versus cementless femoral components and lateral or anterolateral versus posterior anatomical approach. J Orthop Res. 2002;20(2): 182-191.[7] 彭慧明,翁习生.聚醚醚酮材料在骨科植入物的应用进展[J].中华骨科杂志,2011,31(3):265-269.[8] 贾庆卫,汤亭亭,戴克戎.碳增强聚醚醚酮人工关节假体材料的磨损性能研究[J].生物骨科材料与临床研究,2004,1(2):1-4.[9] 俞能宝,董天华,孙俊英.复合材料股骨头的假体生物力学评价[J].中国矫形外科杂志,2001,8(12):1157-1159.[10] 张正廉,孙俊英,孙康.碳纤维增强聚醚醚酮股骨头假体置换术后的即刻稳定性[J].中华创伤骨科杂志,2005,7(10):939-942.[11] 张正廉.CF/PEEK全髋股骨头假体的研制与生物力学实验研究[D].苏州:苏州大学,2004.[12] 奚廷斐.医疗器械生物学评价标准[M].北京:中国标准出版社, 2012.[13] 俞能宝.复合材料全髋股骨头假体研制与生物力学实验研究[D].苏州:苏州医学院,1998.[14] Tilbury C, Holtslag MJ, Tordoir RL, et al. Outcome of total hip arthroplasty, but not of total knee arthroplasty, is related to the preoperative radiographic severity of osteoarthritis. A prospective cohort study of 573 patients. Acta Orthop. 2016; 87(1):67-71.[15] Sirka A, Clauss M, Tarasevicius S, et al. Excellent long-term results of the Müller acetabular reinforcement ring in primary total hip arthroplasty: A prospective study on radiology and survival of 321 hips with a mean follow-up of 11 years. Acta Orthop. 2016;87(2):100-105.[16] Mahmood SS, Mukka SS, Crnalic S, et al. Association between changes in global femoral offset after total hip arthroplasty and function, quality of life, and abductor muscle strength. A prospective cohort study of 222 patients. Acta Orthop. 2016;87(1):36-41. [17] Hjorth MH, Stilling M, Soballe K, et al. No association between pseudotumors, high serum metal-ion levels and metal hypersensitivity in large-head metal-on-metal total hip arthroplasty at 5-7-year follow-up. Skeletal Radiol. 2016;45(1): 115-125.[18] 伍骥,苏斌,吴迪,等.金属对金属人工髋关节假体需要关注的问题[J].中华关节外科杂志:电子版,2010,4(5):671-674.[19] Mazonakis M, Berris T, Lyraraki E, et al. Cancer risk estimates from radiation therapy for heterotopic ossification prophylaxis after total hip arthroplasty. Med Phys. 2013;40(10):101702.[20] Wang L, Lei P, Xie J, et al. Medium-term outcomes of cemented prostheses and cementless modular prostheses in revision total hip arthroplasty. Sci Rep. 2013;3:2796. [21] Pui CM, Bostrom MP, Westrich GH, et al. Increased complication rate following conversion total hip arthroplasty after cephalomedullary fixation for intertrochanteric hip fractures: a multi-center study. J Arthroplasty. 2013;28 (8 Suppl):45-47.[22] Romagnoli S, Zacchetti S, Perazzo P, et al. Simultaneous bilateral total hip arthroplasties do not lead to higher complication or allogeneic transfusion rates compared to unilateral procedures. Int Orthop. 2013;37(11):2125-2130. [23] Sadoghi P, Liebensteiner M, Agreiter M, et al. Revision surgery after total joint arthroplasty: a complication-based analysis using worldwide arthroplasty registers. J Arthroplasty. 2013;28(8):1329-1332. [24] Langton DJ, Sprowson AP, Joyce TJ, et al. Blood metal ion concentrations after hip resurfacing arthroplasty: a comparative study of articular surface replacement and Birmingham Hip Resurfacing arthroplasties. J Bone Joint Surg Br. 2009;91(10):1287-1295. [25] 曹俊奎,黄智华.聚醚醚酮分子结构对流动性和热性能的影响[J].高分子学报,1994,1(1):27-33. [26] Kawamura T, Kurashiki T, Nakai H, et al. Study on a Stiffness Design Method of Femoral Prosthesis Stem Using Fiber Reinforced Composites. Key Eng Mater. 2007;334-335: 1257-1260.[27] Murakami N, Saito N, Takahashi J, et al. Repair of a proximal femoral bone defect in dogs using a porous surfaced prosthesis in combination with recombinant BMP-2 and a synthetic polymer carrier. Biomaterials. 2003;24(13): 2153-2159.[28] Brockett CL, Carbone S, Fisher J, et al. PEEK and CFR-PEEK as alternative bearing materials to UHMWPE in a fixed bearing total knee replacement: An experimental wear study. Wear. 2017;374-375:86-91.[29] Stratton-Powell AA, Pasko KM, Brockett CL, et al. The Biologic Response to Polyetheretherketone (PEEK) Wear Particles in Total Joint Replacement: A Systematic Review. Clin Orthop Relat Res. 2016;474(11):2394-2404.[30] Anguiano-Sanchez J, Martinez-Romero O, Siller HR, et al. Influence of PEEK Coating on Hip Implant Stress Shielding: A Finite Element Analysis. Comput Math Methods Med. 2016; 2016:6183679. [31] Rezaei F, Hassani K, Solhjoei N, et al. Carbon/PEEK composite materials as an alternative for stainless steel/titanium hip prosthesis: a finite element study. Australas Phys Eng Sci Med. 2015;38(4):569-580.[32] Nakahara I, Takao M, Bandoh S, et al. Fixation strength of taper connection at head-neck junction in retrieved carbon fiber-reinforced PEEK hip stems. J Artif Organs. 2014;17(4): 358-363. [33] Brown T, Bao QB, Agrawal CM, et al. An in vitro assessment of wear particulate generated from NUBAC: a PEEK-on-PEEK articulating nucleus replacement device: methodology and results from a series of wear tests using different motion profiles, test frequencies, and environmental conditions. Spine (Phila Pa 1976). 2011;36(26):E1675-1685.[34] Pace N, Marinelli M, Spurio S. Technical and histologic analysis of a retrieved carbon fiber-reinforced poly-ether-ether-ketone composite alumina-bearing liner 28 months after implantation. J Arthroplasty. 2008;23(1): 151-155. [35] 贾庆卫,孙俊英,江宏卫,等.碳增强的聚醚醚酮作为髋臼假体材料的实验研究[J].中国矫形外科杂志,2003,11(3):210-213.[36] Takatori Y, Moro T, Kamogawa M, et al. Poly(2-methacryloyloxyethyl phosphorylcholine)-grafted highly cross-linked polyethylene liner in primary total hip replacement: one-year results of a prospective cohort study. J Artif Organs. 2013;16(2):170-175.[37] Seibert R, Marcellin-Little DJ, Roe SC, et al. Comparison of body weight distribution, peak vertical force, and vertical impulse as measures of hip joint pain and efficacy of total hip replacement. Vet Surg. 2012;41(4):443-447.[38] Gossec L, Paternotte S, Maillefert JF, et al. The role of pain and functional impairment in the decision to recommend total joint replacement in hip and knee osteoarthritis: an international cross-sectional study of 1909 patients. Report of the OARSI-OMERACT Task Force on total joint replacement. Osteoarthritis Cartilage. 2011;19(2):147-154.[39] 康鹏德,沈彬,裴福兴.全髋关节置换术中第二代金属-金属负重界面假体的应用[J].中华骨科杂志,2012,32(2):185-190.[40] 吴荣寰,林向进.髋关节置换后假体无菌性松动机制研究[J].国际骨科学杂志,2007,28(2):122-124.[41] 宋剑,王松,廖振华,等.聚醚醚酮及其改性的人工关节材料的摩擦磨损性能研究进展[J].功能材料, 2014,45(23):23010-23015, 23019.[42] Jayasuriya RL, Buckley SC, Hamer AJ, et al. Effect of sliding-taper compared with composite-beam cemented femoral prosthesis loading regime on proximal femoral bone remodeling: a randomized clinical trial. J Bone Joint Surg Am. 2013;95(1):19-27.[43] Abad C, Maynar M, Ponce G, et al. Implantation of a composite bifurcated cryopreserved aorto-iliac-femoral homograft in a patient with Candida albicans endocarditis. J Cardiovasc Surg (Torino). 2000;41(2):317-319.[44] Fottner A, Schmid M, Birkenmaier C, et al. Biomechanical evaluation of two types of short-stemmed hip prostheses compared to the trust plate prosthesis by three-dimensional measurement of micromotions. Clin Biomech (Bristol, Avon). 2009;24(5):429-434.[45] 董文伟,俞学中,郭乙木.股骨假体远端微动的原因分析[J].浙江大学学报(医学版),2010,39(2):193-197.[46] Saidi K, Ben-Lulu O, Tsuji M, et al. Supracondylar periprosthetic fractures of the knee in the elderly patients: a comparison of treatment using allograft-implant composites, standard revision components, distal femoral replacement prosthesis. J Arthroplasty. 2014;29(1):110-114.[47] Sternheim A, Rogers BA, Kuzyk PR, et al. Segmental proximal femoral bone loss and revision total hip replacement in patients with developmental dysplasia of the hip: the role of allograft prosthesis composite. J Bone Joint Surg Br. 2012; 94(6):762-767.[48] 庞浜,吴琪,管晓东,等.扭转力传递的非骨水泥髋关节假体设计、制作及实验分析[J].中国组织工程研究,2016,20(39): 5794-5800.[49] Judge A, Arden NK, Price A, et al. Assessing patients for joint replacement: can pre-operative Oxford hip and knee scores be used to predict patient satisfaction following joint replacement surgery and to guide patient selection? J Bone Joint Surg Br. 2011;93(12):1660-1664. [50] 吴欣鑫.碳纤维增强聚醚醚酮复合材料及其摩擦磨损性能研究[D].南京:南京理工大学,2012. |

.jpg)

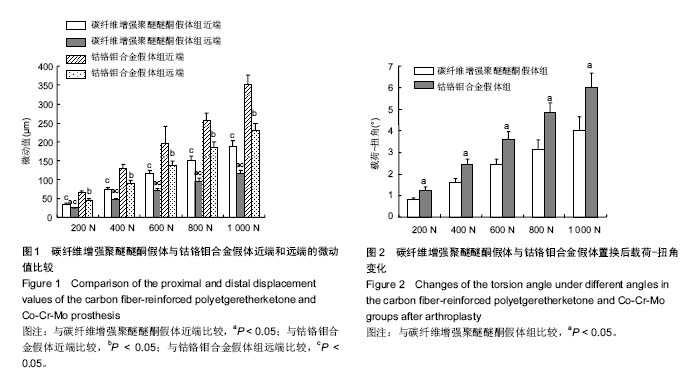

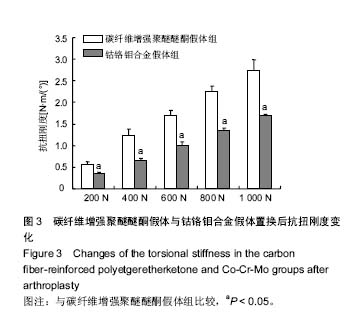

.jpg)