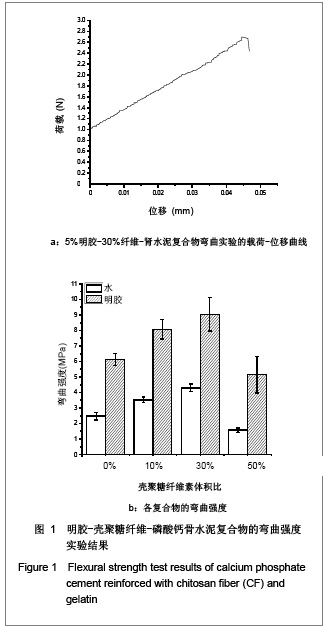

| [1] Larsson S. Calcium phosphates: What is the evidence? J Orthop Trauma. 2010;24:S41-S45.[2] Hu G,Xiao L,Fu H,et al. Study on injectable and degradable cement of calcium sulphate and calcium phosphate for bone repair.J Mater Sci Mater Med. 2010;21(2):627-634. [3] Okada M,Yano K,Namikawa T,et al.Bone Morphogenetic Protein-2 retained in synthetic polymer/β-tricalcium phosphate composite promotes hypertrophy of a vascularized long bone graft in rabbits.Plast Reconstr Surg.2011;127(1): 98-106.[4] Bajammal SS,Zlowodzki M,Lelwica A,et al. The use of calcium phosphate bone cement in fracture treatment.A meta-analysis of randomized trials. J Bone Joint Surg Am. 2008,90(6):1186-1196.[5] Yu B,Han K,Ma H,et al.Treatment of tibial plateau fractures with high strength injectable calcium sulphate. Int Orthop. 2009; 33(4):1127-1133.[6] Iida K,Sudo A,Ishiguro S. Clinical and radiological results of calcium phosphate cement-assisted balloon osteoplasty for Colles' fractures in osteoporotic senile female patients. J Orthop Sci.2010;15(2):204-209.[7] Yoshii T,Dumas JE,Okawa A,et al.Synthesis, characterization of calcium phosphate/polyurethane composites for weight-bearing implants. J Biomed Mater Res B Appl Biomater. 2012;100(1):32-40.[8] Driessens FC, Boltong MG, de Maeyer EA,et al. The Ca/P range of nanoapatitic calcium phosphate cements. Biomaterials. 2002;23(19):4011-4017. [9] Li M, Liu X,Liu X,et al. Creation of macroporous calcium phosphate cements as bone substitutes by using genipin-crosslinked gelatin microspheres. J Mater Sci Mater Med.2009;20(4):925-934. [10] Makarov C,Gotman I,Jiang X,et al.In situ synthesis of calcium phosphate-polycaprolactone nanocomposites with high ceramic volume fractions. J Mater Sci Mater Med.2010;21(6): 1771-1779.[11] Zhao P,Li H,Zhou CR,et al.Cailiao Kexue yu Gongcheng Xuebao. 2010;3(3):390-394. 赵澎,李红,周长忍,等.纤维增强磷酸钙骨水泥[J]. 材料科学与工程学报,2010,3(3):390-394.[12] Xu HH,Quinn JB,Takagi S,et al.Synergistic reinforcement of in situ hardening calcium phosphate composite scaffold for bone tissue engineering. Biomaterials.2004;25(6):1029-1037.[13] Dai HL,Li SP,He JH,et al.Wuji Cailiao Xuebao. 2004;19(5): 1025-1030. 戴红莲,李世普,贺建华,等.碳纤维增强α-TCP/TTCP骨水泥的研究[J].无机材料学报,2004,19(5):1025-1030.[14] Zhao P,Sun KN.Shengwu Guke Cailiao yu Linchuang Yanjiu. 2004;1(3):14-16. 赵萍,孙康宁.纤维增强磷酸钙骨水泥生物复合材料初探[J]. 生物骨科材料与临床研究,2004,1(3):14-16.[15] Shi XT, Xu LX, Shi ZL. Zhongguo Zuzhi Goghcheng Yanjiu yu Linchung Kanxu. 2009;13(38):7474-7476 史雪婷,徐立新,石宗利.聚磷酸钙纤维增强α-磷酸三钙/纳米羟基磷灰石骨水泥复合材料的力学性能[J].中国组织工程研究与临床康复,2009,13(38):7474-7476.[16] Knaul JZ,Hudson SM,Creber KAM. Improved mechanical properties of chitosan fibers.J Appl Poly Sci.1999;72(10): 1721-1732.[17] Bigi A,Bracci B,Panzavolta S. Effect of added gelatin on the properties of calcium phosphate cement. Biomaterials.2004; 25(14):2893-2899.[18] Pan ZH,Fan QY,Jiang PP,et al.Zhongguo Jiaoxing Waike Zazhi. 2009;17(17):1334-1337. 潘朝晖,范清宇,蒋萍萍,等.壳聚糖纤维及明胶联合增强的磷配钙骨水泥理化性能及生物相容性研究[J].中国矫形外科杂志,2009, 17(17):1334-1337.[19] Xu HHK,Quinn JB. Calcium phosphate cement containing resorbable fibers for short-term reinforcement and macroporosity. Biomaterials.2002;23(1):193-202.[20] Pan ZH,Jiang PP.Zhongguo Zuzhi Gongcheng Yanjiu yu Linchuang Kangfu. 2007;11(31):6169-6172. 潘朝晖,蒋萍萍. 明胶改性壳聚糖纤维表征及其体内降解特点[J].中国组织工程研究与临床康复,2007,11(31):6169-6172. |