中国组织工程研究 ›› 2023, Vol. 27 ›› Issue (16): 2493-2500.doi: 10.12307/2023.074

• 组织工程骨材料 tissue-engineered bone • 上一篇 下一篇

双相磷酸钙涂覆羟基磷灰石多孔支架的制备及性能

李京娜1,2,曾庆丰3,4,于树印3,秦 月3,艾子政5,董谢平1,6,7,8

- 1江西省人民医院骨科,江西省南昌市 330006;2江西中医药大学研究生院,江西省南昌市 330004;3 迈海材料基因组国际研究院,河北省廊坊市 065500;4西北工业大学材料学院,陕西省西安市 710072;5南昌市第四医院,江西省南昌市 330104;6南昌大学医学院,江西省南昌市 330006;7江西省卫生健康数字骨科重点实验室,江西省南昌市 330006;8南方科技大学医院南方科技大学粤港澳智能与数字外科创新中心,广东省深圳市 518000

Preparation and properties of porous hydroxyapatite scaffolds with biphase calcium phosphate coating

Li Jingna1, 2, Zeng Qingfeng3, 4, Yu Shuyin3, Qin Yue3, Ai Zizheng5, Dong Xieping1, 6, 7, 8

- 1Department of Orthopedics, Jiangxi Provincial People’s Hospital, Nanchang 330006, Jiangxi Province, China; 2Graduate School of Jiangxi University of Chinese Medicine, Nanchang 330004, Jiangxi Province, China; 3MSEA International Institute for Materials Genome, Langfang 065500, Hebei Province, China; 4School of Materials Science and Engineering, Northwestern Polytechnical University, Xi’an 710072, Shaanxi Province, China; 5The Fourth Hospital of Nanchang, Nanchang 330104, Jiangxi Province, China; 6Medical College of Nanchang University, Nanchang 330006, Jiangxi Province, China; 7Digital Lab of Orthopeadics, Key Laboratory of Health Commission of Jiangxi Province, Nanchang 330006, Jiangxi Province, China; 8Intelligent and Digital Surgery Innovation Center of SUSTech, Southern University of Science and Technology Hospital, Shenzhen 518000, Guangdong Province, China

摘要:

文题释义:

陶瓷浆料3D打印技术:是一种新型技术,不需要预制打印丝线,能够直接将陶瓷材料在常温下逐点逐线逐层打印成型,这不但能显著降低现有的打印耗材成本,而且能够自由搭配材料组合,实现多种材料复合打印,极大地拓展现有打印材料的选择范围,在多孔骨支架材料制造方面有广泛的应用前景。采用陶瓷浆料3D打印技术可以实现个性化人工骨定制。生物活性陶瓷材料:是指用作特定的生物或生理功能的一类陶瓷材料,即直接用于人体或与人体相关的生物、医用、生物化学等的陶瓷材料,主要包括:羟基磷灰石、磷酸三钙及其复合物的生物陶瓷材料,可以负载生物活性物质用于骨诱导和血管形成,被广泛应用于组织修复用的多孔骨组织支架。

背景:目前的人工骨大多只能制备成小体积的填充用材料,大段负重骨及大块结构性植骨材料仍面临缺乏理想骨缺损修复材料和材料成型过程难以加工调控两大难题。

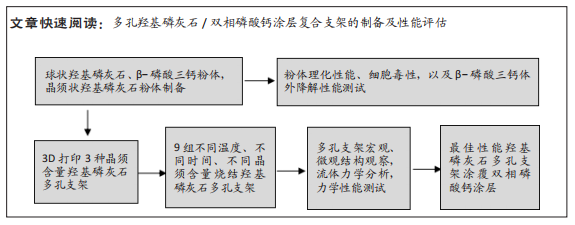

目的:制备与人体大段负重骨形貌结构相似且兼具一定力学性能、优良生物相容性和部分可降解性的多孔羟基磷灰石/双相磷酸钙涂层复合支架,评估其性能。

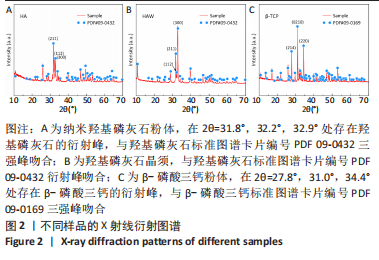

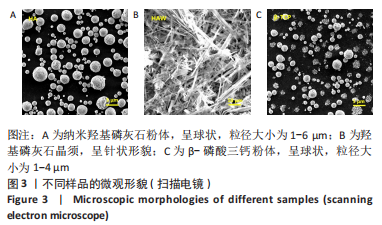

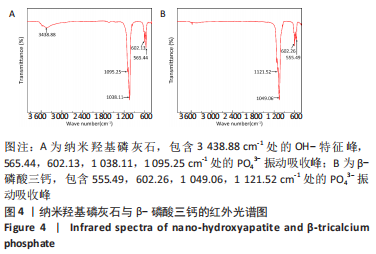

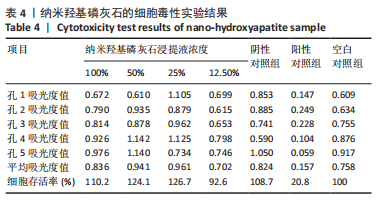

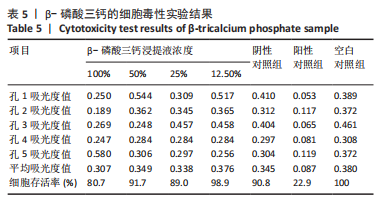

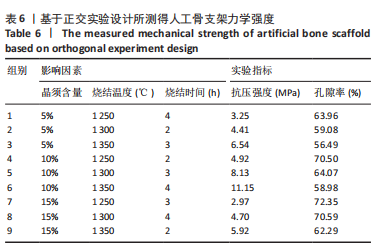

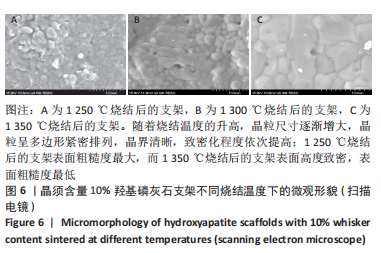

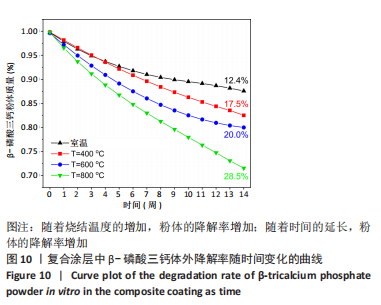

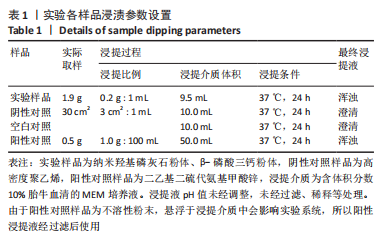

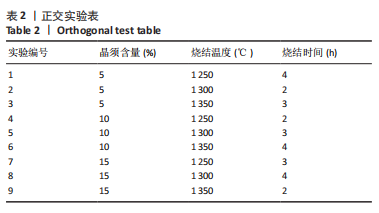

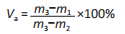

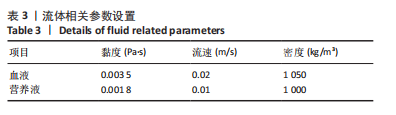

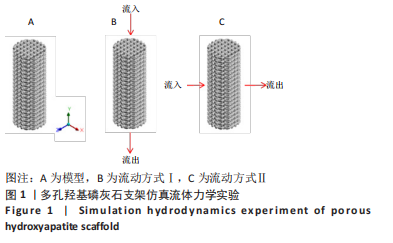

方法:采用水热合成法结合喷雾干燥技术分别制备羟基磷灰石粉体、羟基磷灰石晶须和β-磷酸三钙粉体,评估羟基磷灰石粉体、β-磷酸三钙粉体浸提液的细胞毒性。在羟基磷灰石粉体中添加不同含量(5%,10%,15%)的晶须,借助3D打印技术制备成多孔骨支架,设置不同的烧结工艺,通过正交实验筛选力学性能、孔隙率等最优的晶须含量与烧结工艺组合,检测最优组合支架的流体力学。采用浸渍提拉法将双相磷酸钙涂层涂覆在多孔骨支架上,体外评估双相磷酸钙涂层中β-磷酸三钙粉体的降解性能。

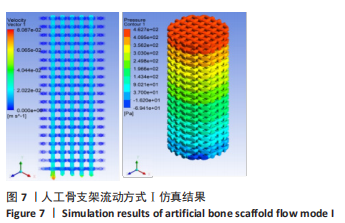

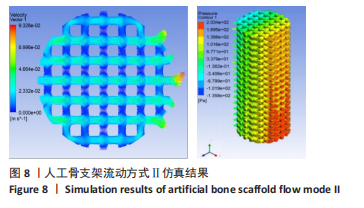

结果与结论:①MTT实验显示,羟基磷灰石粉体、β-磷酸三钙粉体无明显的细胞毒性;②正交实验结果显示,影响多孔支架抗压强度最主要的因素为烧结温度,其次是晶须含量,最后是烧结时间;各因素组合中的最优组合为晶须含量10%、烧结温度1 300 ℃、烧结时间3 h,

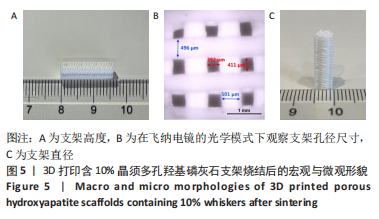

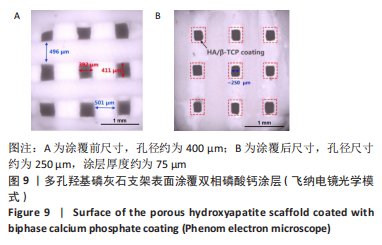

此时支架抗压强度为8.13 MPa,孔隙率为64.07%;③通过流体力学模拟仿真可知,细胞营养液等垂直人工骨横截面方向流入流出的方式更有利于支架在人体中发挥作用;④在飞纳电镜的光学模式下,浸渍涂层前多孔支架的孔径为400 μm,浸渍涂层后多孔支架的孔径为

250 μm,涂层厚度约为75 μm;复合涂层中的β-磷酸三钙具有良好的体外降解性能;⑤结果显示,制备的羟基磷灰石/双相磷酸钙涂层复合支架具有较高的孔隙率与力学性能、优异的生物相容性和部分可降解性,是一种优良的生物活性陶瓷支架。

https://orcid.org/0000-0002-3115-5887(李京娜);https://orcid.org/0000-0002-3881-3192(董谢平)

中图分类号: