[1] NIU J, SONG D, ZHOU H, et al. Percutaneous kyphoplasty for the treatment of osteoporotic vertebral fractures with intravertebral fluid or air: a comparative study. Clin Spine Surg. 2017;30(8):367-373.

[2] 王红旗.骨水泥弥散状况对骨质疏松性胸腰椎椎体骨折经皮椎体后凸成形术效果的影响[J].新乡医学院学报,2019,36(11):1074-1077.

[3] 陈骥,汪洋,杨涵,等.骨填充网袋椎体成形术治疗新鲜骨质疏松压缩性骨折的临床疗效[J]局解手术学杂志,2020,29(10):808-811.

[4] MARTIKOS K, GREGGI T, FALDINI C, et al. Osteoporotic thoracolumbar compression fractures: long-term retrospective comparison between vertebroplasty and conservative treatment. Eur Spine J. 2018;27(Suppl 2):244-247.

[5] FILIPPIADIS DK, MARCIA S, MASALA S, et al. Percutaneous vertebroplasty and kyphoplasty: current status, new developments and old controversies. Cardiovasc Intervent Radiol. 2017;40(12):1815-1823.

[6] TSOUMAKIDOU G, TOO CW, KOCH G, et al. CIRSE guidelines on percutaneous vertebral augmentation. Cardiovasc Intervent Radiol. 2017;40(3):331-342.

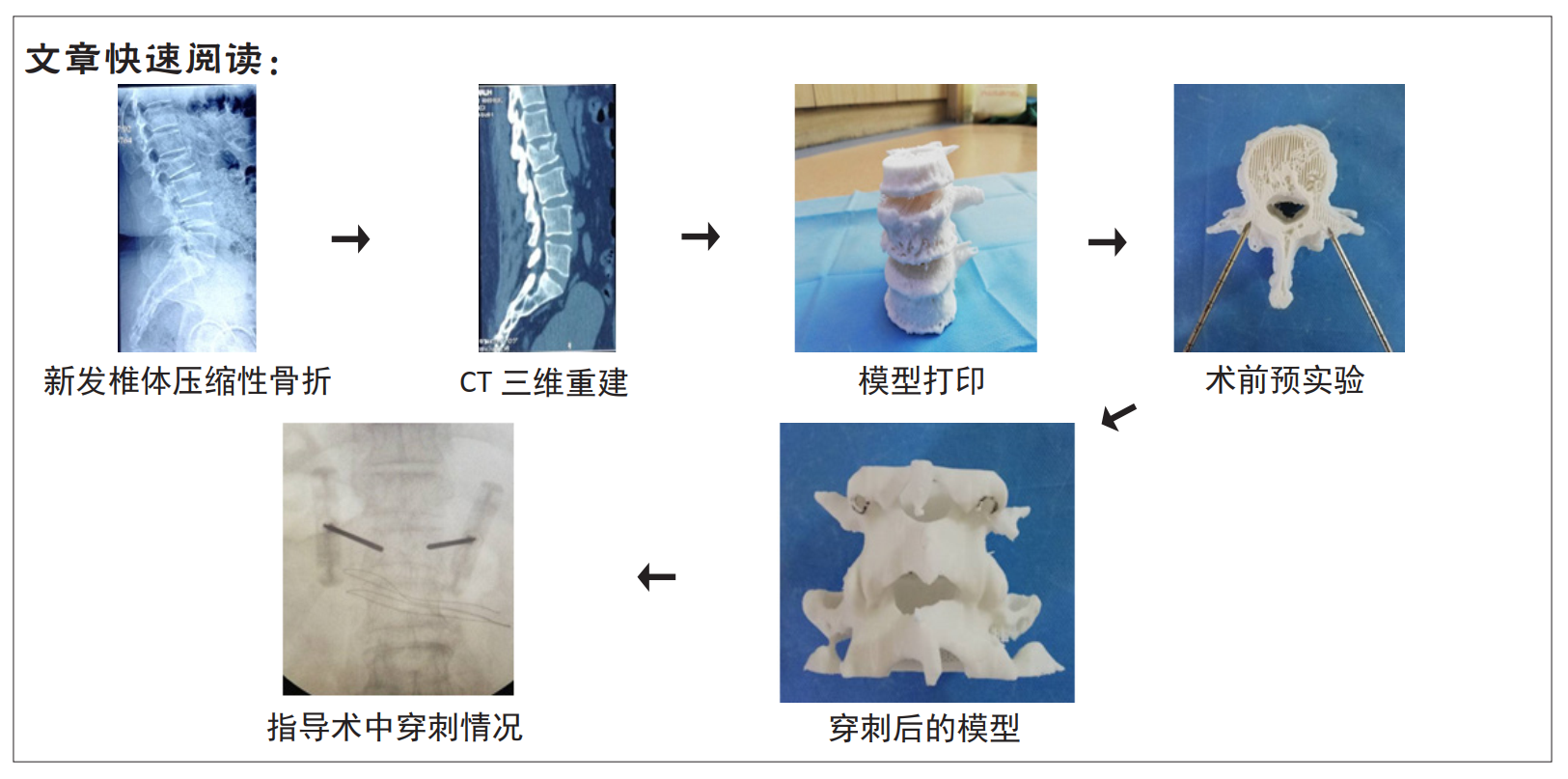

[7] 张佳园,周全,赵加力,等.3D打印点接触导板在胸腰段骨质疏松性椎体压缩性骨折经皮椎体成形治疗中的应用[J].中国组织工程研究,2019,23(12): 1853-1858.

[8] 范国鑫,扶青松,顾广飞,等.脊柱微创手术的辐射危害及其防护进展[J].中国脊柱脊髓杂志,2014,24(3):275-278.

[9] 沈凯,张胜利,谭祖键,等.经皮椎体后凸成形术治疗骨质疏松性椎压缩性骨折中单侧与双侧弥散对疗效的影响[J].中华创伤杂志,2018,34(6):527.

[10] YILMAZ A, ÇAKIR M, YÜCETAŞ CŞ, et al. Percutaneous kyphoplasty: is bilateral approach necessary? Spine (Phila Pa 1976). 2018;43(14):977-983.

[11] 罗平,漆建鑫,陈学明,等.高黏度骨水泥在骨质疏松性胸腰椎压缩性骨折患者经皮椎体成形术中的应用效果[J].山东医药,2017,57(21):61-63.

[12] SHIM J, LEE K, KIM H, et al. Outcome of balloon kyphoplasty for the treatment of osteoporotic vertebral compression fracture in patients with rheumatoid arthritis. BMC Musculoskelet Disord. 2016;17(1):365.

[13] BRUNS N, KRETTEK C. 3D-druck in der unfallchirurgie: planung, druck und aufbereitung [3D-printing in trauma surgery: planning, printing and processing. Unfallchirurg. 2019;122(4):270-277.

[14] 杨志荣,张世科.骨质疏松性椎体压缩性骨折3D打印技术的临床应用[J].广州医药,2019,50(2):97-99.

[15] VIJAYAVENKATARAMAN S, YAN WC, LU WF, et al. 3D bioprinting of tissues and organs for regenerative medicine. Adv Drug Deliv Rev. 2018;132:296-332.

[16] MOON KH, KANG JS, WON MH, et al. The usefulness of three-dimensional computed tomography as an assessment of periacetabular osteolysis in revision total hip arthroplasty. Hip Pelvis. 2015;27(2):90-97.

[17] VAISHYA R, PATRALEKH MK, VAISH A, et al. Publication trends and knowledge mapping in 3D printing in orthopaedics. J Clin Orthop Trauma. 2018;9(3):194-201.

[18] 陆建华,陈维凯,罗宗平.数字骨科3D打印技术辅助经皮椎体后凸成形术治疗OVCF的临床效果[J].江苏医药,2019,45(7):684-688.

[19] 龙浩,白波,卢永辉,等.自行研制的经皮胸腰椎椎弓根植钉三维定位器应用可行性试验研究[J].中华创伤骨科杂志,2011,13(4):358-361.

[20] 常丽鹂,申军,赵敏,等.3D打印数字技术辅助经皮穿刺椎体成形术治疗重度骨质疏松性椎体压缩性骨折的临床效果[J].安徽医药,2019,40(12):1327-1331.

[21] YE LQ, LIANG D, JIANG XB, et al. Risk factors for the occurrence of insufficient cement distribution in the fractured area after percutaneous vertebroplasty in osteoporotic vertebral compression fractures. Pain Physician. 2018;21(1):E33-E42.

[22] BONNARD E, FOTI P, KASTLER A, et al. Percutaneous vertebroplasty under local anaesthesia: feasibility regarding patients’ experience. Eur Radiol. 2017;27(4):1512-1516.

[23] 费琦,赵凡,孟海,等.术前数字化设计辅助的改良椎体成形术治疗骨质疏松性椎体压缩性骨折[J].中华医学杂志,2016,96(9):731-735.

[24] 崔嘉明,杨大志.脊柱转移瘤治疗策略:3D打印技术与精确治疗带来的优势[J].中国组织工程研究,2019,23(36):5875-5881.

[25] YANG JS, LIU JJ, CHU L, et al. Causes of residual back pain at early stage after percutaneous vertebroplasty: a retrospective analysis of 1,316 cases. Pain Physician. 2019;22(5):E495-E503.

[26] VAN MEIRHAEGHE J, BASTIAN L, BOONEN S, et al. A randomized trial of balloon kyphoplasty and nonsurgical management for treating acute vertebral compression fractures: vertebral body kyphosis correction and surgical parameters. Spine (Phila Pa 1976). 2013;38(12):971-983.

[27] 李楠,张贵林,何达,等.骨水泥的分布与剂量对椎体成形术疗效影响的研究[J].中国骨与关节损伤杂志,2015,30(1):66-68.

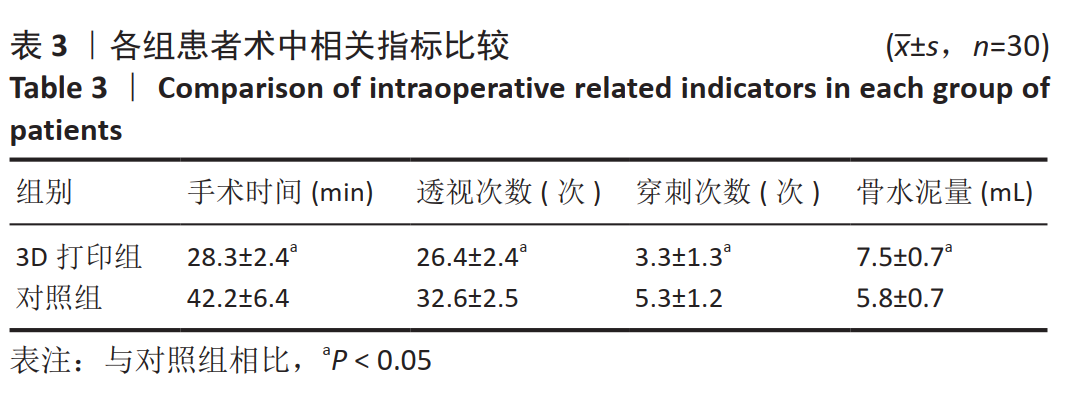

[28] 袁伶俐,徐文弟,耿春辉,等.精确穿刺小剂量骨水泥在PVP术中的应用[J].中国骨与关节损伤杂志,2018,33(1):13-16.

[29] 文坤树,蔡勇平,张家金,等.PKP术中骨水泥的灌注量与分布对OVCF早期疗效的影响[J].重庆医学,2016,45(1):62-65.

[30] 杨小彬,贺宝荣,郝定均,等.不同骨水泥量在PKP术后对相邻节段生物力学影响的有限元分析[J].中国骨与关节损伤杂志,2016,30(1):40-43.

[31] 杨惠林,刘昊,殷国勇,等.我国经皮椎体后凸成形术治疗骨质疏松性椎体骨折现状与创新[J].中华骨质疏松和骨矿盐疾病杂志, 2017,10(1):12-19. |