| [1] Brunner A, Wedi E, Babst R, et al. Bilateral fracture of the medial clavicles treated by open reduction and internal fixation using angle stable locking T-plates. Injury Extra. 2008;39(2):276-278.

[2] Goswami T, Markert RJ, Anderson CG, et al. Biomechanical evaluation of a pre-contoured clavicle plate. J Shoulder Elbow Surg. 2008;17(5):815-818.

[3] Postacchini F, Gumina S, De Santis P, et al. Epidemiology of clavicle fractures. J Shoulder Elbow Surg. 2002;11(5):452-456.

[4] Hughes PJ, Maggs B. Fractures of the clavicle in adults. Curr Orthop. 2002;16(2):133-138.

[5] Harnroongroj T, Tantikul C, Keatkor S. The clavicular fracture: a biomechanical study of the mechanism of clavicular fracture and modes of the fracture. J Med Assoc Thai. 2000;83(6):663-667.

[6] Iannotti MR, Crosby LA, Stafford P, et al. Effects of plate location and selection on the stability of midshaft clavicle osteotomies: a biomechanical study. J Shoulder Elbow Surg. 2002t;11(5):457-462.

[7] Lampasi M, Bochicchio V, Bettuzzi C, et al. Sternoclavicular physeal fracture associated with adjacent clavicle fracture in a 14-year-old boy: a case report and literature review. Knee Surg Sports Traumatol Arthrosc. 2008;16(7):699-702.

[8] Al-Yassari G, Hetzenauer M, Tauber M, et al. Novel method to treat sterno-clavicular joint instability and medial clavicle fracture symptomatic nonunion. J Shoulder Elbow Surg. 2009;18(4):553-555.

[9] Harnroongroj T, Vanadurongwan V. Biomechanical aspects of plating osteosynthesis of transverse clavicular fracture with and without inferior cortical defect. Clin Biomech (Bristol, Avon). 1996;11(5): 290-294.

[10] Demirhan M, Bilsel K, Atalar AC, et al. Biomechanical comparison of fixation techniques in midshaft clavicular fractures. J Orthop Trauma. 2011;25(5): 272-278.

[11] Kayanja MM, Togawa D, Lieberman IH. Biomechanical changes after the augmentation of experimental osteoporotic vertebral compression fractures in the cadaveric thoracic spine. Spine J. 2005;5(1):55-63.

[12] Harnroongroj T, Jeerathanyasakun Y. Intramedullary pin fixation in clavicular fractures: A study comparing the use of small and large pins. J Orthop Surg (Hong Kong). 2000;8(2):7-11.

[13] Gaitanis IN, Carandang G, Phillips FM, et al. Restoring geometric and loading alignment of the thoracic spine with a vertebral compression fracture: effects of balloon (bone tamp) inflation and spinal extension. Spine J. 2005;5(1):45-54.

[14] Asavamongkolkul A, Harnroongroj T, Suteeraporn W, et al. The second fracture of the same clavicle: prevalence and fracture configurations. J Med Assoc Thai. 2012;95(12):1524-1527.

[15] Wu JH, Liao QD, Chen G, et al. Clavicular hook plate in the treatment of dislocation of acromioclavicular joint and fracture of distal clavicle. Zhong Nan Da Xue Xue Bao Yi Xue Ban. 2006;31(4):595-598.

[16] Brekelmans WA, Poort HW, Slooff TJ. A new method to analyse the mechanical behaviour of skeletal parts. Acta Orthop Scand. 1972;43(5):301-317.

[17] Rybicki EF, Simonen FA, Weis EB Jr. On the mathematical analysis of stress in the human femur. J Biomech. 1972;5(2):203-215.

[18] 钱齐荣.骶髂关节与骨盆三维有限元模型的建立与应力分布的理论研究[D].上海:第二军医大学,1997.

[19] Huang CH, Liau JJ, Huang CH, et al. Stress analysis of the anterior tibial post in posterior stabilized knee prostheses. J Orthop Res. 2007;25(4):442-449.

[20] Liau JJ, Cheng CK, Huang CH, et al. The effect of malalignment on stresses in polyethylene component of total knee prostheses--a finite element analysis. Clin Biomech (Bristol, Avon). 2002;17(2):140-146.

[21] Huang CH, Liau JJ, Huang CH, et al. Influence of post-cam design on stresses on posterior-stabilized tibial posts. Clin Orthop Relat Res. 2006;450:150-156.

[22] Lin KJ, Huang CH, Liu YL, et al. Influence of post-cam design of posterior stabilized knee prosthesis on tibiofemoral motion during high knee flexion. Clin Biomech (Bristol, Avon). 2011;26(8):847-852.

[23] Assor M, Aubaniac JM. Influence of rotatory malposition of femoral implant in failure of unicompartimental medial knee prosthesis. Rev Chir Orthop Reparatrice Appar Mot. 2006;92(5):473-484.

[24] Hanson GR, Suggs JF, Kwon YM, et al. In vivo anterior tibial post contact after posterior stabilizing total knee arthroplasty. J Orthop Res. 2007;25(11):1447-1453.

[25] Cheng CK, Huang CH, Liau JJ, et al. The influence of surgical malalignment on the contact pressures of fixed and mobile bearing knee prostheses--a biomechanical study. Clin Biomech (Bristol, Avon). 2003;18(3):231-236.

[26] Yang RS, Lin HJ. Contact stress on polyethylene components of a new rotating hinge with a spherical contact surface. Clin Biomech (Bristol, Avon). 2001; 16(6):540-546.

[27] Chandran N, Amirouche F, Gonzalez MH, et al. Optimisation of the posterior stabilised tibial post for greater femoral rollback after total knee arthroplasty--a finite element analysis. Int Orthop. 2009;33(3): 687-693.

[28] Perillo-Marcone A, Taylor M. Effect of varus/valgus malalignment on bone strains in the proximal tibia after TKR: an explicit finite element study. J Biomech Eng. 2007;129(1):1-11.

[29] Akasaki Y, Matsuda S, Shimoto T, et al. Contact stress analysis of the conforming post-cam mechanism in posterior-stabilized total knee arthroplasty. J Arthroplasty.2008;23(5):736-743.

[30] Hamai S, Miura H, Matsuda S, et al. Contact stress at the anterior aspect of the tibial post in posterior-stabilized total knee replacement. J Bone Joint Surg Am. 2010;92(8):1765-1773.

[31] Giffin JR, Stabile KJ, Zantop T, et al. Importance of tibial slope for stability of the posterior cruciate ligament deficient knee. Am J Sports Med. 2007; 35(9):1443-1449.

[32] Li G, Papannagari R, Most E, et al. Anterior tibial post impingement in a posterior stabilized total knee arthroplasty. J Orthop Res. 2005;23(3):536-541.

[33] Argenson JN, Scuderi GR, Komistek RD, et al. In vivo kinematic evaluation and design considerations related to high flexion in total knee arthroplasty. J Biomech. 2005;38(2):277-284.

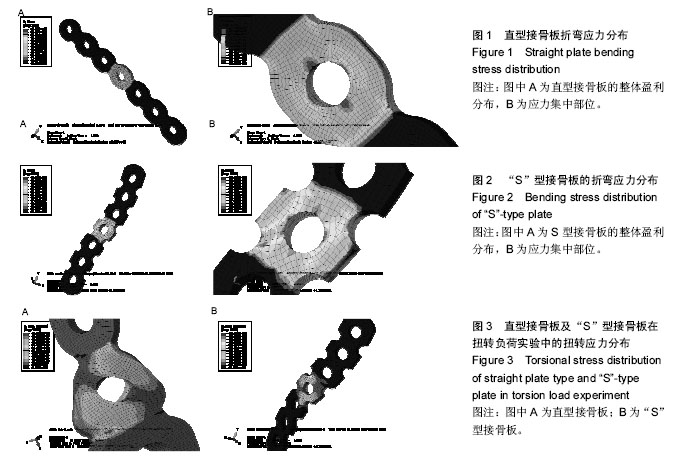

[34] 贺锦阳.个性化解剖型接骨板的有限元分析研究[D].太原:山西医科大学,2012.

[35] 张云鹏.计算机辅助设计制作股骨远端个性化解剖型接骨板的基础理论研究[D].太原:山西医科大学,2010. |

.jpg)

.jpg)

.jpg)