Chinese Journal of Tissue Engineering Research ›› 2015, Vol. 19 ›› Issue (12): 1858-1863.doi: 10.3969/j.issn.2095-4344.2015.12.011

Previous Articles Next Articles

Chitosan improves the crystallization of silk fibroin: a three-dimensional scaffold material with better mechanical stability

Zhang Xia-zhi, Situ Fang-min, Peng Peng, Jiao Yan-peng

- Department of Materials Science and Engineering, Jinan University, Guangzhou 510632, Guangdong Province, China

-

Revised:2015-02-16Online:2015-03-19Published:2015-03-19 -

Contact:Jiao Yan-peng, M.D., Master’s supervisor, Researcher, Department of Materials Science and Engineering, Jinan University, Guangzhou 510632, Guangdong Province, China -

About author:Zhang Xia-zhi, Studying for master’s degree, Department of Materials Science and Engineering, Jinan University, Guangzhou 510632, Guangdong Province, China -

Supported by:the National Natural Science Foundation of China, No. 50903039, 81101151; the Research Fund for the Excellent Doctorial Dissertation of Guangdong Province, No. sybzzxm201034

CLC Number:

Cite this article

Zhang Xia-zhi, Situ Fang-min, Peng Peng, Jiao Yan-peng. Chitosan improves the crystallization of silk fibroin: a three-dimensional scaffold material with better mechanical stability[J]. Chinese Journal of Tissue Engineering Research, 2015, 19(12): 1858-1863.

share this article

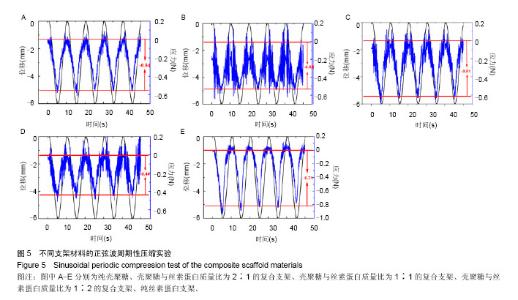

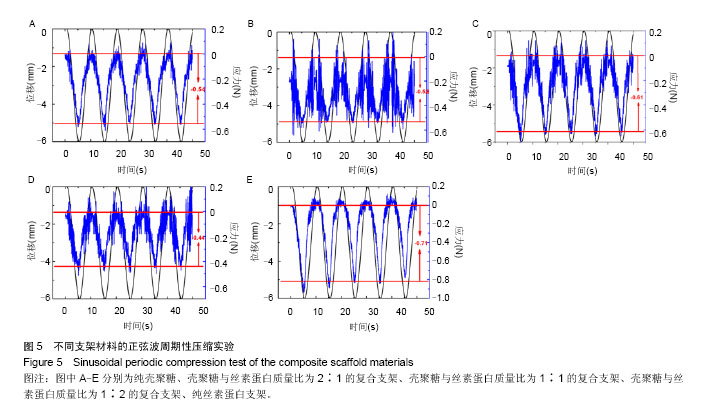

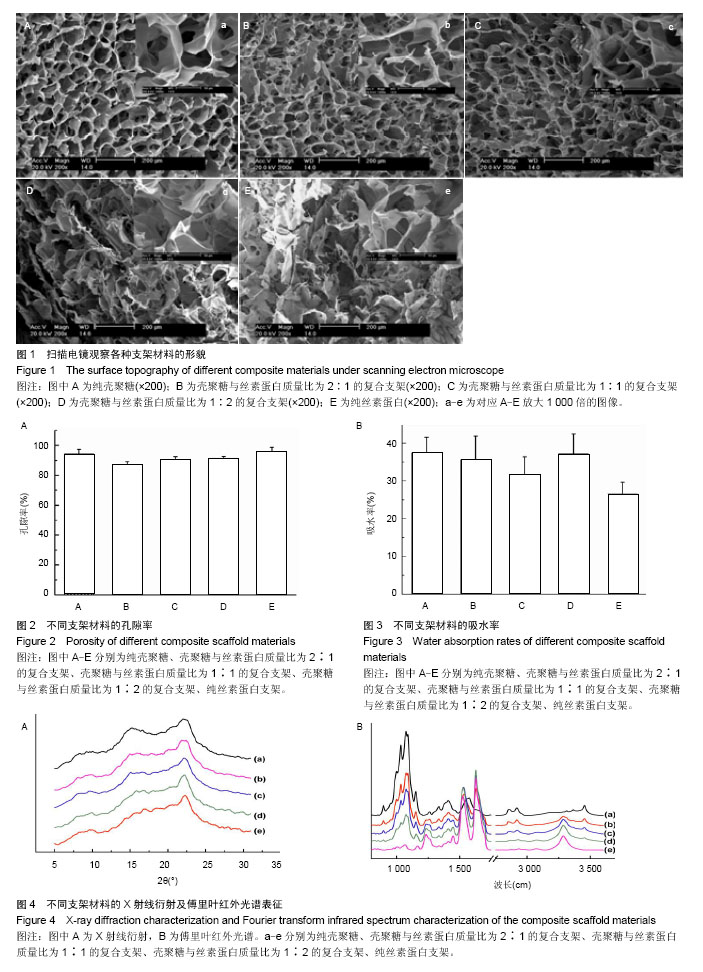

2.1 扫描电镜观察支架材料形貌 由图1显示,混入壳聚糖使得丝素蛋白/壳聚糖支架的孔隙结构比纯丝素蛋白支架更均匀有序,并且壳聚糖含量越高复合支架的孔隙分布越均匀、有序。由此可知,壳聚糖的加入可有效抑制丝素蛋白片层结构的生成,明显改善复合支架的孔隙结构。 2.2 支架材料孔隙率测试 结果图2显示,不同配比的支架孔隙率表现得极为不同,复合支架的孔隙率较纯壳聚糖或者丝素蛋白支架均变小,其中壳聚糖含量越高,复合支架的孔隙率越低,支架结构较为致密,当壳聚糖与丝素蛋白的混合质量比例为2∶1时,在复合支架中的孔隙率最低,支架材料最致密,可推测得壳聚糖组分的加入可以改变支架的孔隙结构。 2.3 支架材料吸水率测试结果 图3显示,不同配比制备的复合支架材料在吸水率上表现出较明显的不同,当壳聚糖与丝素蛋白的混合质量比为1∶2时,吸水率最高,同时明显高于丝素蛋白支架材料,与壳聚糖支架材料相当。支架材料的吸水率主要与支架材料本身的亲疏水性有关,同时也与孔隙率有关系。 2.4 支架材料X射线衍射图 图4A显示的是不同支架材料的X射线衍射图谱,8°、15°、22°对应壳聚糖的特征2 θ角,随着壳聚糖含量的减少,壳聚糖的峰强逐渐减弱。SilkⅠ的主要衍射峰为12.2°、19.7°、24.7°、28.2°;而SilkⅡ的主要衍射峰为9.1°、18.9°和20.7°。经冷冻干燥制成的丝素多孔材料没有出现SilkⅠ和SilkⅡ结构的特征峰,说明此多孔材料的聚集态结构以无定型结构为主。 2.5 支架材料傅里叶红外光谱图 图4B显示,冷冻干燥丝素在1 650,1 545,1 241 cm-1处分别显示了典型的酰胺Ⅰ、酰胺Ⅱ和酰胺Ⅲ结构,分别对应着丝素的无轨卷曲结构、β-折叠、无轨卷曲结构。丝素蛋白的酰胺Ⅱ峰主要与N-H平面弯曲及C-H伸缩振动相关,它们能够参与分子内氢键的形成并导致β-折叠结构的出现。壳聚糖的红外图谱显示,在1 035,1 083 cm-1出现的峰归属于壳聚糖糖环上的C-O-C和C-O的伸缩振动峰。同时在1 598,1 652 cm-1处存在壳聚糖上酰胺基团的特征吸收峰,分别是C=O的伸缩振动峰,酰胺Ⅰ带;N-H的弯曲振动峰,酰胺Ⅱ带。甲醇处理后丝素蛋白的红外图谱显示(图4B),在1 626,1 527,1 234 cm-1左右的峰归属于丝素蛋白的β-折叠构象的特征吸收峰,分别对应于酰胺Ⅰ带、酰胺Ⅱ带,酰胺Ⅲ带。因为形成β-折叠,而出现蓝移。处理后壳聚糖的1 650 cm-1的特征峰消失掉了,证明壳聚糖与丝素蛋白发生了分子间的相互作用。1 409 cm-1是壳聚糖的-COOH基团特征峰,因为样品用0.1 mol/L NaOH处理过,所以消失了[10]。"

| [1] Zhao C,Asakura T.Structure of silk studied with NMR.Prog Nucl Magn Reson Spectrosc.2001;39(4):301-352. [2] Santin M,Motta A,Freddi G,et al.In vitro evaluation of the inflammatory potential of the silk fibroin.J Biomed Mater Res. 1999;46(3):382-389. [3] Sugihara A,Sugiura K,Morita H,et al.Promotive effects of a silk film on epidermal recovery from full-thickness skin wounds. Proc Soc Exp Biol Med.2000;225(1):58-64. [4] Minoura N,Tsukada M,Nagura M.Physico-chemical properties of silk fibroin membrane as a biomaterial.Biomaterials. 1990; 11(6):430-434. [5] Zhang Y,Venugopal JR,El-Turki A,et al.Electrospun biomimetic nanocomposite nanofibers of hydroxyapatite/chitosan for bone tissue engineering. Biomaterials. 2008;29(32):4314-4322. [6] Costa-Pinto AR,Correlo VM,Sol PC,et al.Osteogenic differentiation of human bone marrow mesenchymal stem cells seeded on melt based chitosan scaffolds for bone tissue engineering applications. Biomacromolecules.2009;10(8): 2067-2073. [7] Liuyun J,Yubao L,Chengdong X.Preparation and biological properties of a novel composite scaffold of nano-hydroxyapatite/chitosan/carboxymethyl cellulose for bone tissue engineering.J Biomed Sci.2009;16:65. [8] Bhardwaj N,Nguyen QT,Chen AC,et al.Potential of 3-D tissue constructs engineered from bovine chondrocytes/silk fibroin-chitosan for in vitro cartilage tissue engineering. Biomaterials.2011;32(25):5773-5781. [9] Ahman A,Yan Y,Matthias N.Human adipose-derived stem cells seeded on a silk fibroin-chitosan scaffold enhance wound repair in a murine soft tissue injury model. Stem Ceils.2009;27(1):250-258. [10] Lu Q,Hu X,Wang X,et al.Water-insoluble silk films with silk I structure. Acta Biomaterialia.2010;6(4):1380-1387. [11] Badylak SF,Nerem RM.Progress in tissue engineering and regenerative medicine. Proc Nat Acad Sci.2010;107(8): 3285-3286. [12] Muzzarelli RA.Chitosan composites with inorganics, morphogenetic proteins and stem cells, for bone regeneration. Carbohydr Polym.2011;83(4):1433-1445. [13] Ölmez S,Korkusuz P,Bilgili H,et al.Chitosan and alginate scaffolds for bone tissue regeneration.Pharmazie.2007; 62(6): 423-431. [14] Taveira SF,Nomizo A,Lopez RF.Effect of the iontophoresis of a chitosan gel on doxorubicin skin penetration and cytotoxicity. J Control Release.2009;134(1):35-40. [15] Veleirinho B,Coelho DS,Dias PF,et al.Nanofibrous poly (3-hydroxybutyrate-co-3-hydroxyvalerate)/chitosan scaffolds for skin regeneration. Int J Biol Macromol.2012;51(4): 343-350. [16] Chen J,Li Q,Xu J,et al.Study on biocompatibility of complexes of collagen–chitosan–sodium hyaluronate and cornea. Artif Organs.2005;29(2):104-113. [17] Paolicelli P,de la Fuente M,Sánchez A,et al.Chitosan nanoparticles for drug delivery to the eye.Expert Opin Drug Deliv.2009;6(3):239-253. [18] Majumdar S,Hippalgaonkar K,Repka MA.Effect of chitosan, benzalkonium chloride and ethylenediaminetetraacetic acid on permeation of acyclovir across isolated rabbit cornea.Int J Pharm.2008;348(1-2):175-178. [19] Kundu B,Rajkhowa R,Kundu SC,et al.Silk fibroin biomaterials for tissue regenerations.Adv Drug Deliv Rev.2013;65(4): 457-470. [20] Gholipourmalekabadi M,Mozafari M,Bandehpour M,et al.Optimization of nanofibrous silk fibroin scaffolds as a delivery system for bone marrow adherent cells. Biotechnol Appl Biochem.2014. [Epub ahead of print] [21] Yan LP,Oliveira JM,Oliveira AL,et al.Macro/microporous silk fibroin scaffolds with potential for articular cartilage and meniscus tissue engineering applications. Acta Biomaterialia. 2012;8(1):289-301. [22] Zhang X,Baughman CB,Kaplan DL.In vitro evaluation of electrospun silk fibroin scaffolds for vascular cell growth. Biomaterials.2008;29(14):2217-2227. [23] Yin A,Li J,Bowlin GL,et al.Fabrication of cell penetration enhanced poly (l-lactic acid-co-?-caprolactone)/silk vascular scaffolds utilizing air-impedance electrospinning. Colloids Surf B Biointerfaces. 2014;120:47-54. [24] Gotoh Y,Ishizuka Y,Matsuura T,et al.Spheroid formation and expression of liver-specific functions of human hepatocellular carcinoma-derived FLC-4 cells cultured in lactose− silk fibroin conjugate sponges. Biomacromolecules.2011;12(5): 1532-1539. [25] Fang Q,Chen D,Yang Z,et al.In vitro and in vivo research on using Antheraea pernyi silk fibroin as tissue engineering tendon scaffolds. Mater Sc Eng C.2009;29(5):1527-1534. [26] Bray LJ,George KA,Ainscough SL,et al.Human corneal epithelial equivalents constructed on Bombyx mori silk fibroin membranes.Biomaterials. 2011;32(22):5086-5091. [27] Bhardwaj N,Sow WT,Devi D,et al.Correction: Silk fibroin–keratin based 3D scaffolds as a dermal substitute for skin tissue engineering.Integr Biol. 2014;7(1):142-142. [28] Noishiki Y,Nishiyama Y,Wada M,et al.Mechanical properties of silk fibroin–microcrystalline cellulose composite films.J Nanosci Nanotechnol.2002;86(13):3425-3429. [29] Kweon H,Ha HC,Um IC,et al.Physical properties of silk fibroin/ chitosan blend films.J Appl Polym Sci. 2001;80(7):928-934. |

| [1] | Li Li, Ma Li. Immobilization of lactase on magnetic chitosan microspheres and its effect on enzymatic properties [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 576-581. |

| [2] | Li Xinping, Cui Qiuju, Zeng Shuguang, Ran Gaoying, Zhang Zhaoqiang, Liu Xianwen, Fang Wei, Xu Shuaimei. Effect of modification of β-tricalcium phosphate/chitosan hydrogel on growth and mineralization of dental pulp stem cells [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(22): 3493-3499. |

| [3] | Chen Siyu, Li Yannan, Xie Liying, Liu Siqi, Fan Yurong, Fang Changxing, Zhang Xin, Quan Jiayu, Zuo Lin. Thermosensitive chitosan-collagen composite hydrogel loaded with basic fibroblast growth factor retards ventricular remodeling after myocardial infarction in mice [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(16): 2472-2478. |

| [4] | Liu Feng, Zhang Yu, Wang Yanli, Luo Wei, Han Chaoshan, Li Yangxin. Application of temperature-sensitive chitosan hydrogel encapsulated exosomes in ischemic diseases [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(16): 2479-2487. |

| [5] | Li Jie, Xu Jianzhen, Hu Ping, Lei Qiqi, Zhang Wenning, Ao Ningjian . Preparation and performance evaluation of carboxymethyl chitosan/oxidized glucomannan/Panax notoginseng compound sponge dressing for chronic wound [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(16): 2528-2534. |

| [6] | Chen Zhenyu, Zhang Xiaoning, Luo Yuxin, Liang Jianwei, Yan Chi. Evaluation of silk fibroin/curcumin composite film for promoting wound healing [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(16): 2554-2561. |

| [7] | Xu Changkui, Pu Xiaobing, Lu Yao, Chen Jiarong, Pan Lei. Safety and antibacterial properties of gentamicin-loaded silk fibroin in meniscus repair [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(10): 1545-1549. |

| [8] | Feng Xiaoxia, Hou Weiwei, Jin Xiaoting, Wang Xinhua. Construction of periodontal biomimetic membrane with electrospun poly(lactic-co-glycolic acid) nanofibers and electrosprayed chitosan microspheres [J]. Chinese Journal of Tissue Engineering Research, 2020, 24(4): 511-516. |

| [9] | Li Li, Ma Li, Li He. Preparation and characterization of magnetic chitosan microspheres [J]. Chinese Journal of Tissue Engineering Research, 2020, 24(4): 577-582. |

| [10] | Liu Haiyan, Hu Yang, Wu Xiuping, Pan Haobo, Jing Xuan. Chitosan-based polysaccharide biomaterial for prevention and treatment of oral diseases [J]. Chinese Journal of Tissue Engineering Research, 2020, 24(4): 631-636. |

| [11] | Liao Jian, Huang Xiaolin, Huo Hua, Zhou Qian, Cheng Yuting, Qi Yuhan, Wu Chao, Yang Tongjing, Liao Yunmao, Liang Xing. Effects of calcined bone/chitosan composite materials on proliferation and adhesion in osteoblasts [J]. Chinese Journal of Tissue Engineering Research, 2020, 24(34): 5447-5453. |

| [12] | Fang Yulu, Yi Bingcheng, Shen Yanbing, Tang Han, Zhang Yanzhong. Potential of corn husk fibers reinforced chitosan-based hydrogels in cartilage tissue engineering scaffold [J]. Chinese Journal of Tissue Engineering Research, 2020, 24(34): 5493-5501. |

| [13] | Liao Jian, Huang Xiaolin, Zhou Qian, Huo Hua, Qi Yuhan, Wu Chao, Shi Qianhui, Yang Tongjing, Liao Yunmao, Liang Xing. Calcined bone/chitosan composite promotes osteogenic differentiation of bone marrow mesenchymal stem cells in Sprague-Dawley rats [J]. Chinese Journal of Tissue Engineering Research, 2020, 24(31): 4941-4947. |

| [14] | Liu Xiaoyin, , Zhong Lin, Zheng Bo, Wei Pan, Dai Chen, Hu Liangcong, Wang Tiantian, Liang Xiaolong, Zhang Sai, Wang Xiaoli. Diffusion tensor imaging predicting locomotor function recovery with 3D printing scaffold after spinal cord injury [J]. Chinese Journal of Tissue Engineering Research, 2020, 24(28): 4547-4554. |

| [15] | Liao Jian, Huang Xiaolin, Zhou Qian, Cheng Yuting, Huo Hua, Li Fang, Wu Chao, Shi Qianhui, Liao Yunmao, Liang Xing. Preparation and characterization of calcined bone/chitosan composite material [J]. Chinese Journal of Tissue Engineering Research, 2020, 24(22): 3452-3459. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||