[1] 罗乐,许贤玉,郭慧尔,等.人工心脏瓣膜的研究进展[J].合肥工业大学学报(自然科学版),2008,31(2):305-308+312.

[2] 孙慧萍,王来成,唐会卓,等.人工机械瓣膜置换术后的抗凝药物治疗分析[J].北方药学,2019,16(3):189-191.

[3] 徐志云.人工心脏瓣膜的进展[J].继续医学教育,2006,20(10):63-65.

[4] 崔永春,刘晓鹏,张宏,等.不同种类人工心脏瓣膜的比较及其生物学评价[J].中国医疗器械信息,2016,22(1):2-7+14.

[5] 田子朴,罗传兴,黄旭中,等.双叶机械瓣的研制和临床应用初步报告[J].中华胸心血管外科杂志,1992,8(1):1.

[6] STARR A, EDWARDS ML. Mitral Replacement: Clinical Experience with a Ball-Valve Prosthesis. Ann Surg. 1961;154(4):726-740.

[7] SHINOKA T, BREUER CK, TANEL RE, et al. Tissue engineering heart valves: valve leaflet replacement study in a lamb model. Ann Thorac Surg. 1995;60:S513-S516.

[8] ROTH GA, JOHNSON C, ABAJOBIR A, et al. Global, Regional, and National Burden of Cardiovascular Diseases for 10 Causes, 1990 to 2015[. J Am Coll Cardiol. 2017;70(1):1-25.

[9] 高家红,雷皓,陈群,等.磁共振成像发展综述[J].中国科学:生命科学,2020,50(11):1285-1295.

[10] 宋宏宁,郭瑞强.基于医学影像学的3D打印技术在心血管疾病诊疗中的应用现状及研究进展[J].中国医学影像技术,2017,33(3): 375-380.

[11] GREIL GF, WOLF I, KUETTNER A, et al. Stereolithographic reproduction of complex cardiac morphology based on high spatial resolution imaging. Clin Res Cardiol. 2007;96(3):176-185.

[12] 杜海瑞.仿生人工心脏瓣膜材料多元耦合设计、制备与性能研究[D].长春:吉林大学,2022.

[13] 孟丑拴,洪洋,姜华,等.心脏瓣膜生物力学及相关建模方式的研究进展[J].北京生物医学工程,2023,42(2):212-216.

[14] 袁泉.生物瓣膜瓣叶性能优化及瓣架成型加工方法研究[D].济南:山东大学,2008.

[15] 黄旭.基于ANSYS的生物瓣膜流固耦合力学性能分析[D].济南:山东大学,2014.

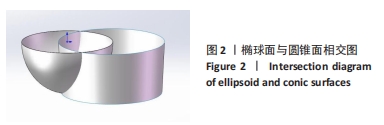

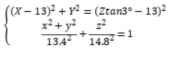

[16] 袁泉,张承瑞.生物瓣支架几何造型CAD系统[J].南京航空航天大学学报,2005,37(Supp1):141-143.

[17] 刘长安.生物瓣膜支架数字化设计与制造[D].济南:山东大学,2009.

[18] 董磊.4D flow MRI在心脏瓣膜病临床应用的研究进展[J].中国医学创新,2021,18(10):185-188.

[19] 朱海燕.基于ANSYS/LS-DYNA的生物瓣膜动态力学性能分析[D].济南:山东大学,2011.

[20] 申炳申.基于FLUENT及LS-DYNA的生物瓣膜流固耦合分析[D].济南:山东大学,2017.

[21] 林金利,董柱,郑燕纯,等.3D打印技术在瓣膜性心脏病诊疗中的应用[J].中国胸心血管外科临床杂志, 2022,29(2):267-271.

[22] 邓欣,沈雳,葛均波.3D打印技术在心血管疾病中的应用进展[J].中国误诊学杂志,2018,13(6):266-269.

[23] 王璐,胡为杰,聂昊,等.3D打印与组织工程心肌、心脏瓣膜、大血管及血管网的构建[J].中国组织工程研究,2015,19(43):7029-7034.

[24] 左进富,孙淼,韩宁宁,等.3D生物打印在组织工程中的应用[J].组织工程与重建外科杂志,2019,15(3):201-203.

[25] VUKICEVIC M, PUPERI DS, JANE GRANDE-ALLEN K, et al. 3D Printed Modeling of the Mitral Valve for Catheter-Based Structural Interventions. Ann Biomed Eng. 2017;45(2):508-519.

[26] 周为.基于模具辅助的心脏主动脉瓣膜3D打印及细胞损伤仿真分析[D].大连:大连理工大学,2019.

[27] 韩刘君,孙尧,于晓龙,等.3D打印技术在心血管疾病中的应用现状[J].西南国防医药,2019,29(12):1267-1269.

[28] 郭睿霖,白龙,焦轩,等.3D打印在心血管外科的临床应用[J].心血管康复医学杂志,2021,30(3):325-329.

[29] SODIAN R, LOEBE M, HEIN A, et al. Application of Stereolithography for Scaffold Fabrication for Tissue Engineered Heart Valves. ASAIO J. 2002;48(1):12-16.

[30] DUAN B. State-of-the-Art Review of 3D Bioprinting for Cardiovascular Tissue Engineering. Ann Biomed Eng. 2017;45(1):195-209.

[31] MAHMOOD F, OWAIS K, TAYLOR C, et al. Three-Dimensional Printing of Mitral Valve Using Echocardiographic Data. JACC Cardiovasc Imaging. 2015;8(2):227-229.

[32] 郭峰.高分子复合材料人工心脏瓣膜制备及其性能研究[D].合肥:中国科学技术大学,2021.

[33] 邹明晖,董念国.组织工程心脏瓣膜支架材料的研究与进展[J].中国组织工程研究与临床康复,2010,14(29):5471-5474.

[34] 王明玉,令文慧,熊春霞,等.3D ECM凝胶支架对干细胞或祖细胞来源心脏细胞行为的影响[J].中国细胞生物学学报,2019,41(10): 2000-2011.

[35] 毛宏理,顾忠伟.生物3D打印高分子材料发展现状与趋势[J].中国材料进展,2018,37(12):949-969+993.

[36] 郭双壮.聚乳酸/聚乙二醇纳米凝胶的合成及性能研究[D].天津:天津大学,2008.

[37] 龚勇吉.聚乳酸/聚乙二醇嵌段共聚物复合材料的制备与性能研究[D].贵阳:贵州大学,2019.

[38] 葛建华,王迎军,郑裕东,等.PLA-PEG-PLA嵌段共聚物的合成及研究[J].材料科学与工程学报,2003(6):817-820.

[39] 曹嘉欣.SLA-3D打印光敏树脂的改性及其性能研究[D].西安:西安科技大学,2020.

[40] HOCKADAY LA, KANG KH, COLANGELO NW, et al. Rapid 3D printing of anatomically accurate and mechanically heterogeneous aortic valve hydrogel scaffolds. Biofabrication. 2012;4(3):035005.

|

(3)

(3)