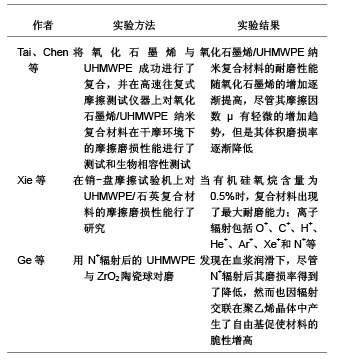

| [1] Ohta M,Hyon SH,Tsutumi S.Control of crystalline orientation to enhance the wear resistance of ultra-high molecular weight polyethylene crystallization cups for artificial joints.Wear.2003; 255:1045-1050.[2] Jacobs JJ.The UHMWPE Handbook.Ultra-High Molecular Weight Polyethylene in Total Joint Replacement.J Bone Joint Surg (Am).2005;87:1906-1906.[3] Geringer J,Witold T,Rouchouse G.Wear behavior of PAEK, poly(aryl-ether-ketone), under physiological conditions, outlooks for performing these materials in the field of hip prosthesis.Wear.2011;271:2793-2803.[4] Burger NDL,DeVaal PL,Meyer JP.Failure analysis on retrieved ultra high molecular weight polyethylene (UHMWPE) acetabular cups.Eng Fail Anal.2007;14:1329-1345.[5] Kobayashi A,Bonfield W,Kadoya Y,et al.The size and shape of particulate polyethylene wear debris in total joint replacements. Proceedings of the Institution of Mechanical Engineers, Part H: Journal of Engineering in Medicine, 1997; 211(1):11-15.[6] Learmonth ID,Young C,Rorabeck C.The operation of the century: total hip replacement. Lancet.2007;370:1508-1519.[7] Xiong L,Xiong DS,Jin JB.Study on Tribological Properties of Irradiated Crosslinking UHMWPE Nano-Composite. J Bionic Eng.2009;6(1):7-13.[8] Plumlee K,Schwartz CJ.Improved wear resistance of orthopaedic UHMWPE by reinforcement with zirconium particles.Wear.2009;267(5-8):710-717.[9] He CX,Shi LP.Tribology property of uhmwpe composites filled with carbon black and tiny glass powder.Mater Sci Technol. 2005;13(14):387-389.[10] Xiong DS. Friction and wear properties of UHMWPE composites reinforced with carbon fiber.Mater Lett.2005; 59 (2-3):175-179.[11] Zoo YS,An JW,Lim DP,et al.Effect of carbon nanotube addition on tribological behavior of UHMWPE.Tribol Lett.2004; 16(4):305-309.[12] Roy S,Pal S.Characterization of silane coated hollow sphere alumina-reinforced ultra high molecular weight polyethylene composite as a possible bone substitute material.Bull Mat Sci.2002;25:609-612.[13] Bradford L,Baker DA,Graham J,et al.Wear and surface cracking in early retrieved highly cross-linked polyethylene acetabular liners. J Bone Joint Surg Am.2004;86:1271-1282.[14] Tai ZX,Chen YF,An YF,et al.Tribological Behavior of UHMWPE Reinforced with Graphene Oxide Nanosheets. Tribol Lett.2012;46:55-63.[15] Chen YF,Qi YY,Tai ZX,et al.Preparation, mechanical properties and biocompatibility of graphene oxide/ultrahigh molecular weight polyethylene composites.Eur Polymer J.2012; 10.1016/j.eurpolymj.2012.03.011.[16] Xie XL,Tang CY,Chan KYY,et al.Wear performance of ultrahigh molecular weight polyethylene/quartz composites. Biomaterials.2003;24:1889-1896.[17] Luo Y,Ge SR.Load dependence of nanohardness in nitrogen ion implanted Ti6Al4V alloy and fractal characterization.J China Univ Min Tech.2007;17:363-367.[18] Wang A,Essner A,Polineni VK,et al.Lubrication and wear of ultra-high molecular weight polyethylene in total joint replacements.Tribol Int.1998;31:17-33.[19] 黄捷,杨丹,屈树新.超高分子量聚乙烯在人工髋关节中的摩擦磨损研究[J].材料导报,2011,25(3):136-140.[20] Paul JP.Force actions transmitted by joints in the human body. Proc R Soc Lond B Biol Sci.1976;192(1107):163-172.[21] Gispert MP,Serro AP,Colaco R,et al.Friction and wear mechanisms in hip prosthesis: Comparison of joint materials behaviour in several lubricants.Wear. 2006;260:149-158.[22] Waters EPJ,Spedding PL,Dohert AP,et al.Wear of the artificial hip joint material under lubrication. Asia Pac J Chem Eng. 2009; 4:80-89.[23] Park HJ,Kwak SY,Kwak S.Wear-Resistant Ultra High Molecular Weight Polyethylene/Zirconia Composites Prepared by in situ Ziegler-Natta Polymerization.Macromol Chem Phys.2005;206:945-950.[24] Yao J,Laurent MP,Gilbertson LN,et al.The effect of minimum load on the fluid uptake and wear of highly crosslinked UHMWPE total hip acetabular components.Wear.2001;250: 140-144.[25] Samad MA,Sinha SK. Dry sliding and boundary lubrication performance of a UHMWPE/CNTs nanocomposite coating on steel substrates at elevated temperatures.Wear.2011;270: 395-402.[26] Gladkis LG,Timmers H,Scarvell JM,et al. Detailed three-dimensional size and shape characterisation of UHMWPE wear debris.Wear.2011;270:455-463. |