| [1] 为小春.关节软骨[M].北京:科学出版社,2007. [2] Hunter W.Of the Structure and Disease of Articulating Cartilages. Clin Orthop Relat Res.1995; 42(317):3-6. [3] 樊瑜波,蒲放.康复辅具与生物力学[J].医用生物力学, 2016,31(6): 476-477. [4] 马钢,肖云峰,刘晓民,等.组织工程支架在骨软骨修复中的应用进展[J].医学综述,2019,25(3):453-458. [5] 张姝江,王瑛,陈艺,等.生物力学在关节软骨修复中的作用[J].中华关节外科杂志(电子版),2018,12(6):842-848. [6] 袁清献,高丽兰,李瑞欣,等.3D打印丝素蛋白-Ⅱ型胶原软骨支架[J].山东大学学报(理学版),2018,53(3):82-87. [7] 王小虎,卫小春,张全有,等.正常软骨细胞力学特性的研究[J].中华医学杂志, 2007,87(13):916-920. [8] Rowson DT,Shelton JC,Screen HRC,et al.Mechanical loading induces primary cilia disassembly in tendon cells via TGFβ and HDAC6.Scientific Rep.2018;8(1):11107. [9] De Palma A,Cheleschi S,Pascarelli NA,et al.Hydrostatic pressure as epigenetic modulator in chondrocyte cultures: A study on miRNA-155, miRNA-181a and miRNA-223 expression levels.J Biomech. 2018;66:165-169. [10] Praxenthaler H,Krämer E,Weisser M,et al.Extracellular matrix content and WNT/β-catenin levels of cartilage determine the chondrocyte response to compressive load.Biochim Biophys Acta Mol Basis Dis. 2018;1864(3):851-859. [11] Amin K,Ziad A,Salvatore F,et al.A compression system for studying depth-dependent mechanical properties of articular cartilage under dynamic loading conditions.Med Eng Phys. 2018;60:103-108. [12] 林祥龙,高丽兰,李瑞欣,等.压缩载荷下软骨细胞/复合支架的三维培养[J].中国组织工程研究,2019,23(10):1483-1488. [13] K.L.Dorrington,孙家驹,马若涓.生物材料的粘弹性理论[J].力学进展, 1988,18(3):396-409. [14] 满喜.生物软组织力学性质的理论研究[D].呼和浩特:内蒙古大学, 2018. [15] 周光泉,刘孝敏.粘弹性理论[M].合肥:中国科学技术大学出版社, 1996. [16] 张义同.热粘弹性理论[M].天津:天津大学出版社,2002. [17] Aliramaji S,Zamanian A,Mozafari M.Super-paramagnetic responsive silk fibroin/chitosan/magnetite scaffolds with tunable pore structures for bone tissue engineering applications.Mater Sci Eng C Mater Biol Appl. 2017;70(Pt 1): 736-744. [18] Li DW,Lei X,He FL,et al.Silk fibroin/chitosan scaffold with tunable properties and low inflammatory response assists the differentiation of bone marrow mesenchymal stem cells.Int J Biol Macromol. 2017;105(Pt 1):584-597. [19] Wang J,Yang Q,Cheng N,et al.Collagen/silk fibroin composite scaffold incorporated with PLGA microsphere for cartilage repair.Mater Sci Eng C Mater Biol Appl.2016;61:705-711. [20] Jeon YH,Choi JH,Sung JK,et al.Different effects of PLGA and chitosan scaffolds on human cartilage tissue engineering.J Craniofac Surg. 2007;18(6):1249-1258. [21] 孙安玉.关节软骨生物力学特性的超声测量方法研究[D].杭州:浙江大学, 2015. [22] 程琴.基于有限元方法的三维细胞模型与力学分析[D].重庆:重庆大学,2009. [23] 刘庆.松质骨的粘弹性力学特性分析[D].广州:暨南大学,2013. [24] Olubamiji AD,Izadifar Z,Si JL,et al.Modulating mechanical behaviour of 3D-printed cartilage-mimetic PCL scaffolds: influence of molecular weight and pore geometry. Biofabrication. 2016;8(2):025020. [25] 彭云.基于ABAQUS的非线性粘弹性本构模型二次开发[J].南昌航空大学学报(自然科学版),2011,25(2):38-41,92. [26] 吴斌,鹿如鑫,严斌,等.基于应力松弛试验的人牙周膜五参数粘弹性模型构建[J].东南大学学报(医学版),2018,37(6):943-950. [27] 郭玉明,张宏民,朱健,等.松质骨粘弹性性质的实验研究[J].中国生物医学工程学报,2000,19(3):272-275. [28] 潘晓明,余俊,杨钊,等.一种将线性粘弹微分型本构方程应用到ABAQUS的方法[J].华侨大学学报(自然科学版),2010,31(5): 570-575. [29] 刘朝丰,鲍文魁,徐景龙,等.剪切模量的近似函数和精确数值积分表达式[J].上海航天,2003,20(5):26-28. [30] 龚兰云,高永毅,张厚安.多孔材料的力学模型和粘弹性性能研究[J].湖南科技大学学报(自然科学版),2010,25(1):34-37. [31] 杨挺青.非线性粘弹理论中的单积分型本构关系[J].力学进展, 1988,18(1):52-60. [32] Courtois A,Marcin L,Benavente M,et al.Numerical Multiscale Homogenization Approach For Linearly Viscoelastic 3D Interlock Woven Composites.Int J Solid Struct.2018. [33] 任立海,蒋成约,陈勇,等.基于动态拉伸试验数据的脑组织粘性–超弹性材料模型参数求解[J].生物医学工程学杂志, 2018,35(5): 767-773,778. [34] 魏龙飞.分数阶粘弹性模型参数识别及其有限元实现[D].成都:西南交通大学, 2018. [35] Bleuel J,Zaucke F,Brüggemann GP,et al. Effects of cyclic tensile strain on chondrocyte metabolism: a systematic review.PLoS One. 2015;10(3):e0119816. [36] Lee D,Erickson A,You T,et al.Pneumatic microfluidic cell compression device for high-throughput study of chondrocyte mechanobiology.Lab Chip.2018;18(14):2077-2086. |

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

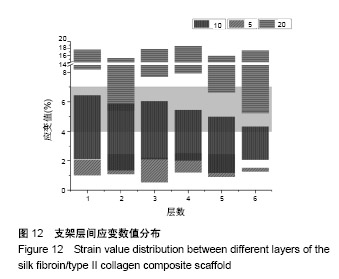

.jpg)

.jpg)

.jpg)