中国组织工程研究 ›› 2019, Vol. 23 ›› Issue (20): 3164-3169.doi: 10.3969/j.issn.2095-4344.1200

• 数字化骨科 digital orthopedics • 上一篇 下一篇

掌指关节假体个体化设计与应用:1例报告

钟 华1,刘 军2,蔡国祥1,段少银1

- 1厦门大学附属中山医院影像科,福建省厦门市 361004;2吉林大学第二医院手外科,吉林省长春市 136000

Individualized design and clinical application of metacarpophalangeal joint prosthesis: a one-case report

Zhong Hua1, Liu Jun2, Cai Guoxiang1, Duan Shaoyin1

- 1Department of Radiology, Zhongshan Hospital of Xiamen University, Xiamen 361004, Fujian Province, China; 2Department of Hand Surgery, the Second Hospital of Jilin University, Changchun 136000, Jilin Province, China

摘要:

文章快速阅读:

.jpg)

文题释义:

计算机辅助设计:根据CT或MR图像重建出所需要的器官模型,然后导入正向工程软件设计出假体骨形态以及人工关节链接方式,通过平移、旋转、缩放改变假体大小及与器官模型的空间位置关系,然后进行组装,布尔运行加减去除他们之间重叠部分,并且计算机辅助设计可以很方便反复进行修改,以得到最优模型。聚醚醚酮:聚醚醚酮可在134 ℃下经受3 000次循环高压灭菌,这一特性能满足灭菌要求高、需反复使用的手术和牙科设备的制造,加上其抗蠕变和耐水解性,用它可制造需高温蒸汽消毒的各种医疗器械。尤为重要的是聚醚醚酮无毒、质轻、耐腐蚀,弹性模型与骨骼相似,是与人体骨骼最接近的材料,具有生物组织相容性,因此可采用聚醚醚酮代替金属制造人体骨骼。

摘要

背景:临床上掌指关节创伤严重毁损后大多直接截肢,此次研究主要尝试对毁损严重的掌指关节进行个体化假体置换,以期恢复患手部分功能。

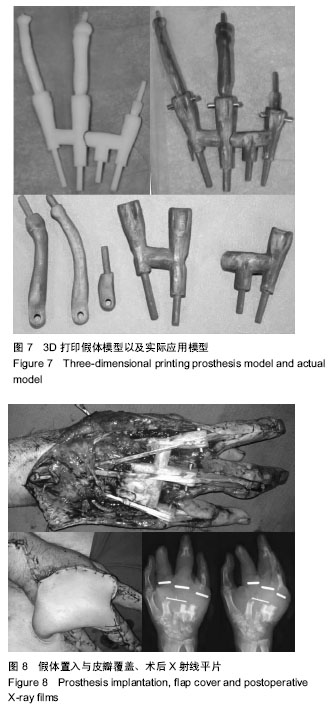

目的:通过3D打印技术与医用级聚醚醚酮材料机加工技术,探讨个体化掌指关节假体的设计、制作与临床应用。

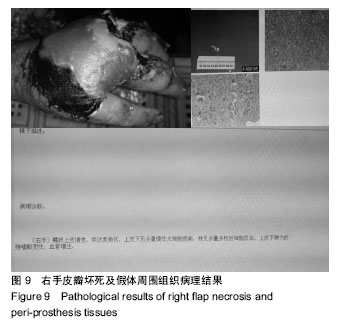

方法:①纳入右手机器绞伤男性患者1例,64岁。采用术前双手薄层螺旋CT扫描数据进行双手三维重建,计算机辅助设计右手掌指关节假体。该临床研究的实施符合《赫尔辛基宣言》和吉林大学第二医院对研究的相关伦理要求[批准号:(2018)年研审第(133),审批时间:2017-08-16];②将右手残存骨质、设计完善的右手掌指关节假体输入3D打印机设备和机加工设备,完成解剖形态个体化的右手掌指关节假体模型复现与制作;③利用打印模型进行术前模拟,术中即刻将掌指关节假体置入。

结果与结论:①基于CT薄层扫描数据完成假体设计与制作,假体与母体吻合,手术复原手部解剖形态,皮瓣移植覆盖;②提示3D打印联合机加工技术实现个体化掌指关节假体的设计和应用为掌指关节毁损修复重建提供了一种方法,该技术的有益尝试可能成为骨修复、置换的新趋势。

中国组织工程研究杂志出版内容重点:人工关节;骨植入物;脊柱;骨折;内固定;数字化骨科;组织工程

ORCID: 0000-0003-3718-8628(钟华)

中图分类号:

.jpg)

.jpg)

.jpg)

.jpg)