中国组织工程研究 ›› 2016, Vol. 20 ›› Issue (47): 6887-7005.doi: 10.3969/j.issn.2095-4344.2016.47.001

• 组织工程骨及软骨材料 tissue-engineered bone and cartilage materials • 下一篇

聚乳酸-羟基乙酸共聚物/硅酸钙三维多孔骨组织工程支架的构建与性能

胡 露1,2,3,魏 坤1,邹 芬1,2,3

- 1华南理工大学材料科学与工程学院,广东省广州市 510640;2国家人体组织功能重建工程技术研究中心,广东省广州市 510006;3广东省生物医学工程重点实验室,广东省广州市 510006

Construction and characteristics of poly(lactic-co-glycolic acid)/calcium silicate scaffolds with three-dimensional pores for bone tissue engineering

Hu Lu1, 2, 3, Wei Kun1, Zou Fen1, 2, 3

- 1School of Material Science and Engineering, South China University of Technology, Guangzhou 510640, Guangdong Province, China; 2National Engineering Research Center for Tissue Restoration and Reconstruction, Guangzhou 510006, Guangdong Province, China; 3Guangdong Provincial Key Laboratory of Biomedical Engineering, Guangzhou 510006, Guangdong Province, China

摘要:

文章快读阅读:

.jpg)

文题释义:

聚乳酸-羟基乙酸共聚物:被广泛用于骨组织工程支架材料,具有良好的生物相容性和降解性,但作为一种人工合成的高分子材料,其也有一定的缺陷,如本身的骨传导性较弱、降解产物偏酸性容易引起炎症反应及机械强度不够等。

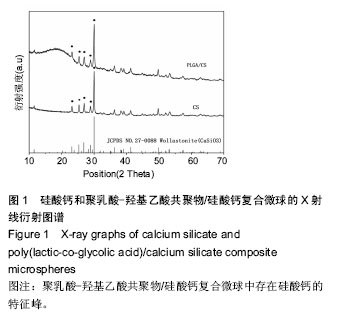

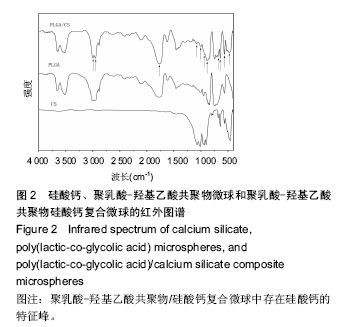

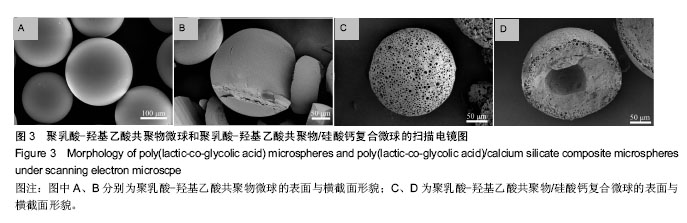

聚乳酸-羟基乙酸共聚物/硅酸钙三维多孔骨组织工程支架:实验首先在聚乳酸-羟基乙酸共聚物微球中加入硅酸钙,制得了具有良好生物相容性和降解性的多孔聚乳酸-羟基乙酸共聚物/硅酸钙复合微球,然后采用生物3D打印设备3D-Bioplotter,利用熔融沉积制造的原理制备了具有三维连通多孔结构的聚乳酸-羟基乙酸共聚物支架;最后利用低温融合技术将聚乳酸-羟基乙酸共聚物/硅酸钙复合微球与聚乳酸-羟基乙酸共聚物支架结合起来,预期构建出一种具有良好生物相容性、降解性、机械强度和三维连通多孔结构的新型骨组织工程支架。

背景:目前的聚乳酸-羟基乙酸共聚物(poly(lactic-co-glycolic acid),PLGA)支架材料存在降解产物呈酸性、力学性能低、孔隙率低、孔径小、孔隙之间的连通率不佳、支架的几何形状不易控制等缺陷。

目的:构建具有三维连通多孔结构的PLGA/硅酸钙骨组织工程支架材料,测试其体外降解性能、力学性能及生物相容性。

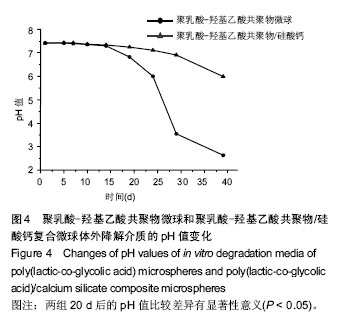

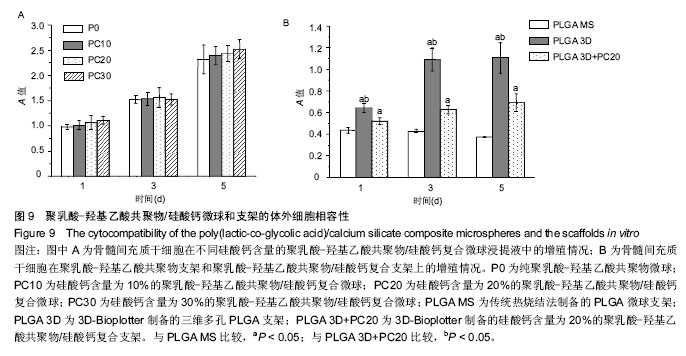

方法:先通过乳液溶剂挥发法制备PLGA/硅酸钙多孔复合微球,3D-Bioplotter制备PLGA三维多孔支架,然后采用低温融合技术将微球与支架结合,制备PLGA/硅酸钙复合多孔支架。检测PLGA/硅酸钙多孔复合微球与PLGA微球的组成成分、形貌及降解性能,检测PLGA三维多孔支架与PLGA/硅酸钙复合多孔支架的形貌、孔隙及压缩强度。分别采用PLGA/硅酸钙多孔复合微球与PLGA微球浸提液,含PLGA三维多孔支架与PLGA/硅酸钙复合多孔支架的培养液培养小鼠骨髓间充质干细胞,1,3,5 d后检测细胞增殖活性。

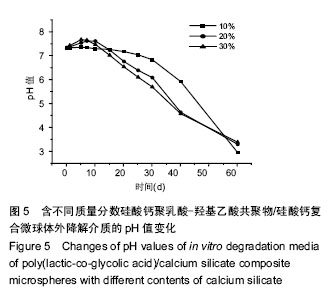

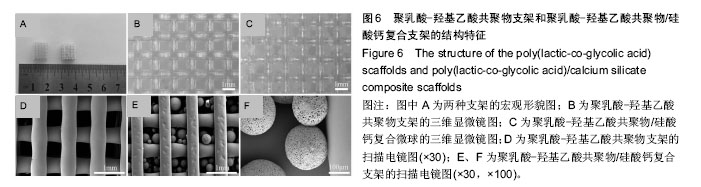

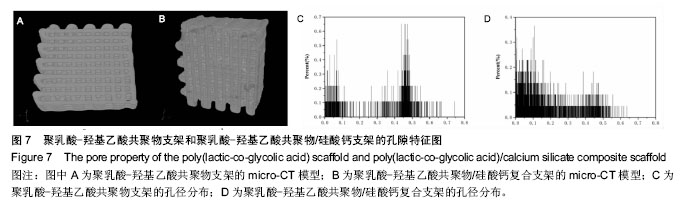

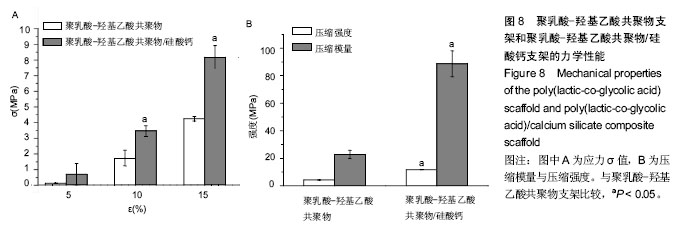

结果与结论:①微球形貌及降解性能:硅酸钙组分的加入,有助于PLGA微球形成表面规则孔结构和内部空腔结构,以及提高PLGA微球降解的pH值;②支架结构:PLGA/硅酸钙复合多孔支架的纤维直径与支架孔径均小于PLGA三维多孔支架;③支架孔隙:PLGA/硅酸钙复合多孔支架的孔隙率与平均孔径均小于PLGA三维多孔支架;④支架力学性能:PLGA/硅酸钙复合多孔支架的压缩强度与压缩模量高于PLGA三维多孔支架(P < 0.05);⑤细胞相容性:骨髓间充质干细胞在两种微球浸提液和两种支架上的生长状况良好;⑥结果表明:PLGA/硅酸钙复合多孔支架具有良好的体外降解性能、力学性能及生物相容性。

中图分类号:

.jpg)