[1] WANG M, LI R, JING J. Establishment and application of lower limb finite element model based on muscle groups. J Mech Med Biol.2018;18(8):1840024.

[2] 李亚楠,钱秀清,孙翠莲,等.大腿假肢支撑期有限元分析[J].北京生物医学工程,2018,37(2):116-121.

[3] LORENZELLI L, SORDO G, BAGOLINI A, et al. Socketmaster: Integrated Sensors System for the Optimised Design of Prosthetic Socket for above Knee Amputees//Cas. 2017.

[4] PATERNÒ L, IBRAHIMI M, GRUPPIONI E, et al. Sockets for limb prostheses: a review of existing technologies and open challenges. IEEE Trans Biomed Eng. 2018;65(9):1996-2010.

[5] HENRIKSON K, WEATHERSBY E, LARSEN B, et al. An inductive sensing system to measure in-socket residual limb displacements for people using lower-limb prostheses.Sensors.2018;18(11): 3840.

[6] 王振泽,徐智,晏菲,等.下肢假肢接受腔对残肢肌肉萎缩影响的数值研究[J].生物医学工程学杂志,2018,35(6):887-891.

[7] LEE W, ZHANG M, JIA X, et al. Finite element modeling of the contact interface between trans-tibial residual limb and prosthetic socket. Med Eng Phys. 2004;26(8):655-662.

[8] ZHANG M, LORD M, TURNER-SMITH AR, et al. Development of a non-linear finite element modelling of the below-knee prosthetic socket interface. Med Eng Phys. 1995;17(8): 559-566.

[9] ZACHARIAH SG, SANDERS JE. Finite element estimates of interface stress in the trans-tibial prosthesis using gap elements are different from those using automated contact. J Biomech. 2000;33(7):895-899.

[10] GOH JCH, LEE PVS, TOH SL, et al. Development of an integrated CAD–FEA process for below-knee prosthetic sockets. Clin Biomech. 2005;20(6):623-629.

[11] PENG HK, HSU LH, HUANG GF, et al. The Analysis and Measurement of Interface Pressures between Stump and Rapid Prototyping Prosthetic Socket Coated With a Resin Layer for Transtibial Amputee//13th International Conference on Biomedical Engineering. Springer, Berlin, Heidelberg. 2009:1720-1723.

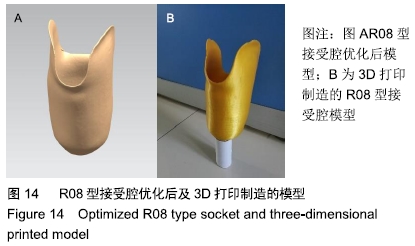

[12] NGUYEN KT, BENABOU L, ALFAYAD S. Systematic Review of Prosthetic Socket Fabrication using 3D printing//Proceedings of the 2018 4th International Conference on Mechatronics and Robotics Engineering. ACM. 2018:137-141.

[13] 徐盼飞.基于Fusion 360协同功能应用的现代家具设计研究[D].成都:西南交通大学,2018.

[14] 张绍岚,李古强,邵长庆.小腿假肢接受腔计算机三维模型的构建[J].中国组织工程研究与临床康复,2010,14(48):8954-8957.

[15] 樊瑜波,蒲放,张明,等.个体化下肢小腿假肢接受腔设计的生物力学评价技术研究[J].中国生物医学工程学报, 2004,23(6):544-548.

[16] 许华丽.基于TRIZ理论的人体假肢优化设计研究[D].杭州:浙江理工大学,2016.

[17] 张明,樊瑜波.小腿假肢接受腔的三维有限元分析[J].生物医学工程学杂志, 2000,17(4):403-406.

[18] ZHANG M, ROBERTS C. Comparison of computational analysis with clinical measurement of stresses on below-knee residual limb in a prosthetic socket. Med Eng Phys. 2000;22(9):607-612.

[19] ZHANG M, MAK AFT, ROBERTS VC. Finite element modelling of a residual lower-limb in a prosthetic socket: a survey of the development in the first decade. Med Eng Phys.1998;20(5): 360-373.

[20] DICKINSON AS, STEER JW, WORSLEY PR. Finite element analysis of the amputated lower limb: a systematic review and recommendations. Med Eng Phys. 2017;43:1.

[21] PETRON A, DUVAL JF, HERR H. Multi-Indenter Device for in Vivo Biomechanical Tissue Measurement. IEEE Transactions on Neural Systems and Rehabilitation Engineering, 2017.

[22] 孔亮,贾振岗,石磊,等.小腿残肢与接受腔界面的摩擦行为分析及测试[J].摩擦学学报,2014(6):650-657.

[23] 穆晨,钱秀清,闫松华,等.预应力下大腿残肢站立中期时相的有限元分析[J].医用生物力学,2011,26(4):321-324.

[24] 张明,麦福达,樊瑜波.小腿假肢接受腔的三维有限元分析[J].生物医学工程学杂志,2000,17(4):403-406.

[25] ZHANG M, LEE WCC. Quantifying the regional load-bearing ability of trans-tibial stumps. Prosthet Orthot Int. 2006;30(1): 25-34.

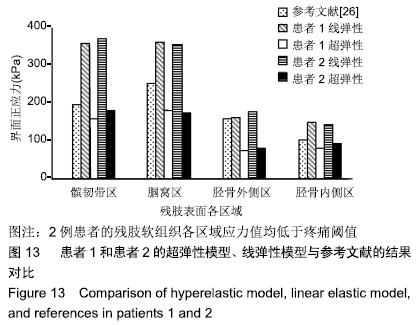

[26] 贾晓红,张明,王人成,等.小腿截肢患者残端应力的三维有限元动态分析[J].中国康复医学杂志,2004,19(5):334-336.

[27] 贾晓红,张明,王人成,等.惯性载荷对截肢患者残肢/接受腔界面应力的影响研究[J].生物医学工程学杂志,2005,22(3):468-471.

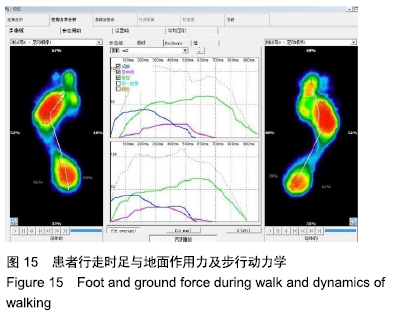

[28] TUAN LV, OHNISHI K, OTSUKA H, et al. Finite element analysis for the estimation of the ground reaction force and pressure beneath the foot prosthesis during the gait of transfemoral patients//Journal of Biomimetics, Biomaterials and Biomedical Engineering. Trans Tech Publications. 2017;33:1-11.

[29] LUENGAS-CONTRERAS LA, CAMARGO-CASALLAS E, GUARDIOLA D. Modeling and simulation of prosthetic gait using a 3-d model of transtibial prosthesis. Revista Ciencias de la Salud. 2018;16(1): 82-100.

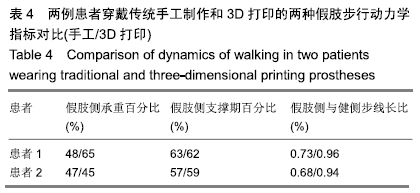

[30] JAIMES ES, BOTÍA GCP, RODRIGUES PH, et al. Comparison of a transtibial socket design obtained by additive manufacturing and reverse engineering and a traditional model//Journal of Physics: Conference Series. IOP Publishing. 2018;1126(1):012016.

[31] HAND B. Reinforced fill-compositing prosthetic apparatus and method of manufacturing: U.S. Patent Application 15/905,523[P]. 2018-8-30.

|