中国组织工程研究 ›› 2019, Vol. 23 ›› Issue (2): 245-250.doi: 10.3969/j.issn.2095-4344.1512

• 膜生物材料 membrane biomaterials • 上一篇 下一篇

面向皮肤支架3D生物打印喷头的CFD模拟与实验

陈冬冬1,张 琦1,张鹏飞2,周骥平1,姜亚妮3

- 1扬州大学机械工程学院,江苏省扬州市 225127;2江苏牧羊控股有限公司,江苏省扬州市 255120;3扬州大学动物科学与技术学院,江苏省扬州市 225009

3D bioprinted nozzle for skin scaffolds: CFD simulation and experiments

Chen Dongdong1, Zhang Qi1, Zhang Pengfei2, Zhou Jiping1, Jiang Yani3

- 1College of Mechanical Engineering, Yangzhou University, Yangzhou 225127, Jiangsu Province, China; 2Su Shepherd Holding Co. (Jiangsu Province) Yangzhou 255120, Jiangsu Province, China; 3College of Animal Science and Technology, Yangzhou University, Yangzhou 225009, Jiangsu Province, China

摘要:

文章快速阅读:

.jpg)

文题释义:

流场模拟:通过限元软件Fluent模拟3D生物打印机在不同压力、温度和不同喷头挤出直径下,实际的喷头流速变化情况。

气动挤压:通过气泵提供动力的来源,可设置不同的挤出压力大小,可以挤出明胶纤维溶液。

3D生物打印技术:是将3D打印技术应用到组织工程中,可实现具有复杂生理结构的一种制造方法,是3D打印技术的一个分支,通过增材制造原理将复杂的器官结构离散成一系列的二维层状结构,这种构建方法显著降低了复杂器官的构建难度,特别在一些异质性组织的构建方面,3D生物打印技术突破了传统制造技术的局限。

背景:随着组织工程的发展,3D生物打印技术可通过打印生物质材料来构建皮肤支架,但工艺参数不明确,打印过程中经常出现堆积和不连续情况。

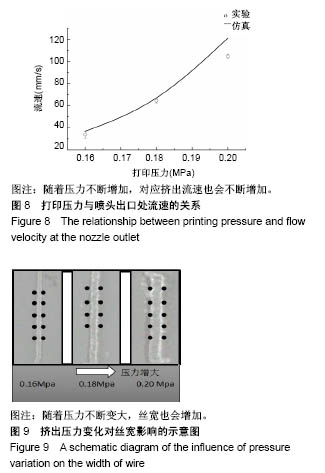

目的:通过3D生物打印机和有限元软件Fluent进行数值模拟,以获得合理的挤出压强、黏度、喷头行走速度、喷头直径、温度参数,解决明胶纤维打印过程中的堆积和不连续问题。

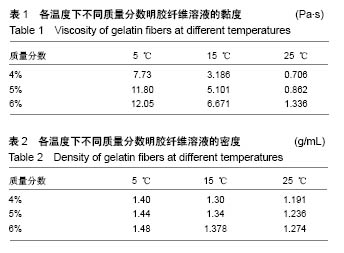

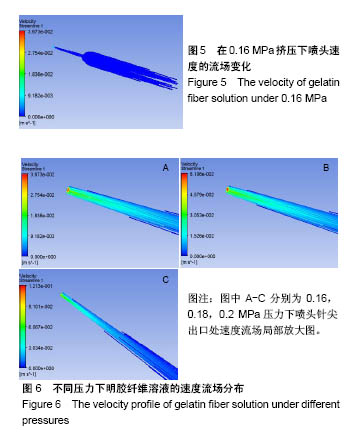

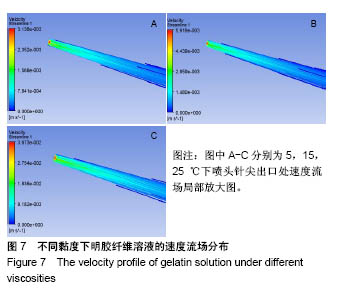

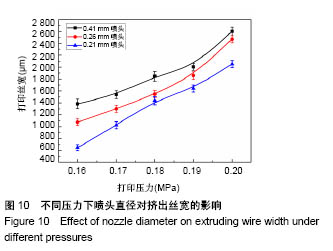

方法:以5%明胶纤维素溶液为打印材料,采用3D生物打印机和限元软件Fluent进行数值模拟,设置打印温度分别为5,15,25 ℃,打印压力分别为0.16,0.18,0.2 MPa,喷头直径分别为0.21,0.26,0.41 mm,检测喷头针尖处的流速与流量;以合适的参数3D打印明胶纤维皮肤生物支架,扫描电镜观察支架结构。

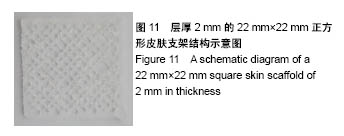

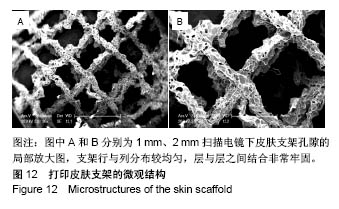

结果与结论:3D生物打印明胶纤维皮肤生物支架过程中,设置打印温度在15 ℃、喷头行走速度为30 mm/s、压力为0.18 MPa、喷头直径为0.21 mm时,可保证喷头挤出的明胶纤维材料不会堆积或者断丝,连续性挤出明胶纤维,并且在上述打印条件下打印的丝宽1 400 μm左右;将此条件下打印的生物支架进行扫描电镜观察,可见支架的行与列分布较均匀,层与层之间的结合部位黏结牢固,不易变形,支架孔隙率约57%。

ORCID: 0000-0001-8332-9693(陈冬冬)

中图分类号:

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)