[1] FERRARI S, PALMERINI E, STAALS EL, et al. The treatment of nonmetastatic high grade osteosarcoma of the extremity: review of the Itali(1(1an Rizzoli experience. Impact on the future. Cancer Treat Res. 2009;152:275-287.

[2] BLÄSIUS F, DELBRÜCK H, HILDEBRAND F, et al. Surgical Treatment of Bone Sarcoma. Cancers (Basel). 2022;14(11):2694.

[3] 郭传平,高冬芳,李羡,等.医用镁合金耐腐蚀性能研究进展[J].稀有金属材料与工程,2024,53(8):2390-2404.

[4] SARIAN MN, IQBAL N, SOTOUDEHBAGHA P, et al. Potential bioactive coating system for high-performance absorbable magnesium bone implants. Bioact Mater. 2021;12:42-63.

[5] LIN X, TAN L, ZHANG Q, et al. The in vitro degradation process and biocompatibility of a ZK60 magnesium alloy with a forsterite-containing micro-arc oxidation coating. Acta Biomater. 2013;9(10):8631-8642.

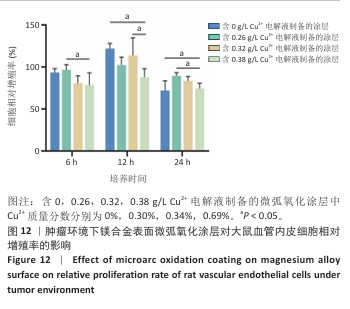

[6] LIANG DY, LIANG PC, YI QQ, et al. Copper coating formed by micro-arc oxidation on pure Mg improved antibacterial activity, osteogenesis, and angiogenesis in vivo and in vitro. Biomed Microdevices. 2021;23(3):39.

[7] 石伟.含锶羟基磷灰石涂层对Mg-4Zn合金腐蚀行为及细胞行为的影响[D].长沙:湖南大学,2017.

[8] 赵颖,曾利兰,梁涛.可降解镁基金属的生物相容性研究进展[J].金属学报,2017,53(10):1181-1196.

[9] NAN M, YANGMEI C, BANGCHENG Y. Magnesium metal--a potential biomaterial with antibone cancer properties. J Biomed Mater Res A. 2014;102(8):2644-2651.

[10] ZENG RC, CUI LY, JIANG K, et al. In Vitro Corrosion and Cytocompatibility of a Microarc Oxidation Coating and Poly(L-lactic acid) Composite Coating on Mg-1Li-1Ca Alloy for Orthopedic Implants. ACS Appl Mater Interfaces. 2016;8(15):10014-10028.

[11] 纪凌宇.AZ91D镁合金基钙磷/壳聚糖复合抗菌膜层生物相容性研究[D].哈尔滨:哈尔滨商业大学,2016.

[12] WU Y, HE G, ZHANG Y, et al. Unique antitumor property of the Mg-Ca-Sr alloys with addition of Zn. Sci Rep. 2016;6:21736.

[13] ZHOU M, TIAN M, LI C. Copper-Based Nanomaterials for Cancer Imaging and Therapy. Bioconjug Chem. 2016;27(5):1188-1199.

[14] TSVETKOV P, COY S, PETROVA B, et al. Copper induces cell death by targeting lipoylated TCA cycle proteins. Science. 2022;375(6586): 1254-1261.

[15] 铙其强.PDA负载金属离子修饰PCL/β-TCP支架表面用于骨组织工程[D].南昌:南昌大学,2021.

[16] LIN Z, CAO Y, ZOU J, et al. Improved osteogenesis and angiogenesis of a novel copper ions doped calcium phosphate cement. Mater Sci Eng C Mater Biol Appl. 2020;114:111032.

[17] ZHOU Y, HAN S, XIAO L, et al. Accelerated host angiogenesis and immune responses by ion release from mesoporous bioactive glass. J Mater Chem B. 2018;6(20):3274-3284.

[18] NOORI A, HOSEINPOUR M, KOLIVAND S, et al. Synergy effects of copper and L-arginine on osteogenic, angiogenic, and antibacterial activities. Tissue Cell. 2022;77:101849.

[19] WANG H, ZHAO S, XIAO W, et al. Influence of Cu doping in borosilicate bioactive glass and the properties of its derived scaffolds. Mater Sci Eng C Mater Biol Appl. 2016;58:194-203.

[20] HASINOFF BB, WU X, YADAV AA, et al. Cellular mechanisms of the cytotoxicity of the anticancer drug elesclomol and its complex with Cu(II). Biochem Pharmacol. 2015;93(3):266-276.

[21] NAGAI M, VO NH, SHIN OGAWA L, et al. The oncology drug elesclomol selectively transports copper to the mitochondria to induce oxidative stress in cancer cells. Free Radic Biol Med. 2012;52(10):2142-2150.

[22] LI CY, GAO L, FAN XL, et al. In vitro degradation and cytocompatibility of a low temperature in-situ grown self-healing Mg-Al LDH coating on MAO-coated magnesium alloy AZ31. Bioact Mater. 2020;5(2):364-376.

[23] YANG SH, LUO X, LI MY, et al. Effect of MAO Parameters on the Degradation Property of Medical Mg-6Zn Alloy Prepared by Semisolid Powder Molding. Transactions of the Indian Institute of Metals. 2023; 76(8):2273-2283.

[24] 杨上挥,罗霞,李铭宇,等.半固态粉末成形温度对Mg-6Zn-xMn显微组织和力学性能的影响[J].粉末冶金材料科学与工程,2022, 27(4):372-381.

[25] 秦静.医用镁合金微弧氧化及其在模拟人体环境下的磨损行为[D].西安:西安工业大学,2016.

[26] LUO X, LI M, CAI H, et al. Degradation Adaptability Assessment of Semisolid Powder Molded Mg-Zn-Mn Alloys for Orthopedic Applications. ACS Appl Bio Mater. 2023;6(12):5515-5530.

[27] GB/T 16886.12-2023,医疗器械生物学评价第12部分:样品制备与参照材料[S].

[28] 侯丽,乔春霞,赵增琳.解读ISO 10993-4:2017《医疗器械生物学评价第4部分:与血液相互作用试验选择》[J].中国医疗设备, 2018,33(11):1-6.

[29] GB/T 16886.5-2017,医疗器械生物学评价第5部分:体外细胞毒性试验[S].

[30] GILL J, GORLICK R. Advancing therapy for osteosarcoma. Nat Rev Clin Oncol. 2021;18(10):609-624.

[31] ISAKOFF MS, BIELACK SS, MELTZER P, et al. Osteosarcoma: Current Treatment and a Collaborative Pathway to Success. J Clin Oncol. 2015; 33(27):3029-3035.

[32] AGARWAL S, CURTIN J, DUFFY B, et al. Biodegradable magnesium alloys for orthopaedic applications: A review on corrosion, biocompatibility and surface modifications. Mater Sci Eng C Mater Biol Appl. 2016;68: 948-963.

[33] ZHANG E, YANG L, XU J, et al. Microstructure, mechanical properties and bio-corrosion properties of Mg-Si(-Ca, Zn) alloy for biomedical application. Acta Biomater. 2010;6(5):1756-1762.

[34] WONG CC, WONG PC, TSAI PH, et al. Biocompatibility and Osteogenic Capacity of Mg-Zn-Ca Bulk Metallic Glass for Rabbit Tendon-Bone Interference Fixation. Int J Mol Sci. 2019;20(9):2191.

[35] XU L, PAN F, YU G, et al. In vitro and in vivo evaluation of the surface bioactivity of a calcium phosphate coated magnesium alloy. Biomaterials. 2009;30(8):1512-1523.

[36] ATKINSON RL, ZHANG M, DIAGARADJANE P, et al. Thermal enhancement with optically activated gold nanoshells sensitizes breast cancer stem cells to radiation therapy. Sci Transl Med. 2010;2(55):55ra79.

[37] 侯莉,徐斌,宋嘉卓,等.仿生壳聚糖基水凝胶的可控构筑及其对多能干细胞生物学行为影响的分析[J].分析化学,2022,50(10):1520-1532.

[38] ZHANG E, YANG L, XU J, et al. Microstructure, mechanical properties and bio-corrosion properties of Mg-Si(-Ca, Zn) alloy for biomedical application. Acta Biomater. 2010;6(5):1756-1762.

[39] WU C, ZHOU Y, XU M, et al. Copper-containing mesoporous bioactive glass scaffolds with multifunctional properties of angiogenesis capacity, osteostimulation and antibacterial activity. Biomaterials. 2013;34(2):422-433.

[40] ROMERO-SÁNCHEZ LB, MARÍ-BEFFA M, CARRILLO P, et al. Copper-containing mesoporous bioactive glass promotes angiogenesis in an in vivo zebrafish model. Acta Biomater. 2018;68:272-285.

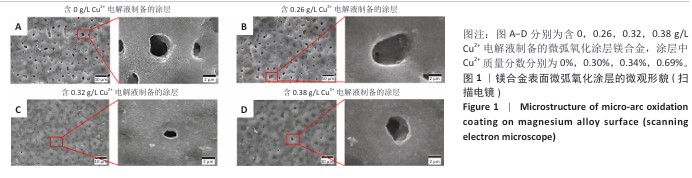

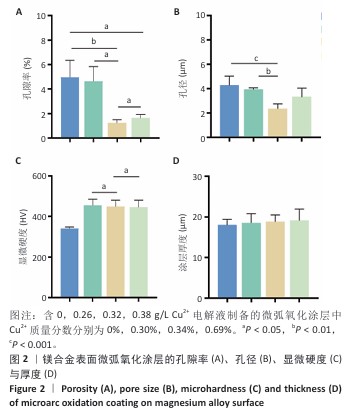

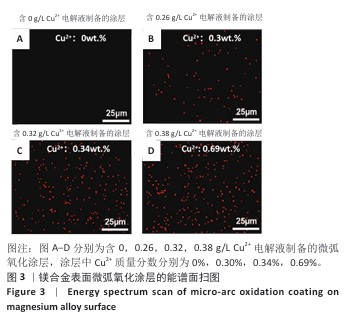

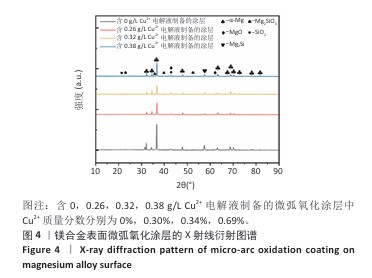

[41] AHMED M, QI Y, ZHANG L, et al. Influence of Cu2+ Ions on the Corrosion Resistance of AZ31 Magnesium Alloy with Microarc Oxidation. Materials (Basel). 2020;13(11):2647.

[42] FU L, XU JL, WANG FP, et al. Biomimetic deposition of apatite coatings on micro-arc oxidation treated biomedical NiTi alloy. Surf Coat Technol. 2010;204:3294-3299.

[43] 刘庆,欧阳雪琼,刘文财,等.流延工艺制备氧化锆燃料电池薄膜的研究进展[J].材料导报,2025,39(10):1-20.

[44] 姜炳春,卢立伟,林标智,等.微/纳米颗粒改性镁合金微弧氧化膜层性能的研究进展[J].中国有色金属学报,2024,34(10): 3308-3324.

[45] BREWER GJ. Copper toxicity in the general population. Clin Neurophysiol. 2010;121(4):459-460.

[46] KIM BE, NEVITT T, THIELE DJ. Mechanisms for copper acquisition, distribution and regulation. Nat Chem Biol. 2008;4(3):176-185.

[47] VALKO M, LEIBFRITZ D, MONCOL J, et al. Free radicals and antioxidants in normal physiological functions and human disease. Int J Biochem Cell Biol. 2007;39(1):44-84.

[48] XU Y, LIU SY, ZENG L, et al. An Enzyme-Engineered Nonporous Copper(I) Coordination Polymer Nanoplatform for Cuproptosis-Based Synergistic Cancer Therapy. Adv Mater. 2022;34(43):e2204733.

[49] ZHONG X, DAI X, WANG Y, et al. Copper-based nanomaterials for cancer theranostics. Wiley Interdiscip Rev Nanomed Nanobiotechnol. 2022;14(4):e1797.

[50] 唐思成.CeO2含量对Al2O3-10TiO2复合陶瓷涂层耐腐蚀性能的影响[D].成都:西华大学,2022.

[51] HOA BT, VUONG BX. Sol-gel synthesis of nano-bioactive glass 60SiO2-36CaO-4P2O5 (mol.%) without using acid catalysts. Sol-Gel Sci Technol. 2024;110:900-909.

[52] SHANBHAG VC, GUDEKAR N, JASMER K, et al. Copper metabolism as a unique vulnerability in cancer. Biochim Biophys Acta Mol Cell Res. 2021;1868(2):118893.

[53] WANG X, SCHRÖDER HC, MÜLLER WE. Enzymatically synthesized inorganic polymers as morphogenetically active bone scaffolds: application in regenerative medicine. Int Rev Cell Mol Biol. 2014;313: 27-77.

[54] MANSO Y, ADLARD PA, CARRASCO J, et al. Metallothionein and brain inflammation. J Biol Inorg Chem. 2011;16(7):1103-1113.

[55] GÉRARD C, BORDELEAU LJ, BARRALET J, et al. The stimulation of angiogenesis and collagen deposition by copper. Biomaterials. 2010; 31(5):824-831.

[56] 杨淑,崔文国,魏杰,等.自愈合可注射性透明质酸水凝胶的构建及促进血管生成的研究[J].上海交通大学学报(医学版),2023, 43(12):1480-1492.

[57] BARRALET J, GBURECK U, HABIBOVIC P, et al. Angiogenesis in calcium phosphate scaffolds by inorganic copper ion release. Tissue Eng Part A. 2009;15(7):1601-1609.

[58] TSVETKOV P, COY S, PETROVA B, et al. Copper induces cell death by targeting lipoylated TCA cycle proteins. Science. 2022;375(6586): 1254-1261. |