Chinese Journal of Tissue Engineering Research ›› 2013, Vol. 17 ›› Issue (3): 496-500.doi: 10.3969/j.issn.2095-4344.2013.03.019

Previous Articles Next Articles

Medical ultra-high molecular weight polyethylene modification and tribological characteristics

Si Qing-zong, An Xiao-li, An Ying-fei, Liu Bin

- College of Stomatology, Lanzhou University, Lanzhou 730000, Gansu Province, China

-

Received:2012-03-13Revised:2012-05-11Online:2013-01-15Published:2013-02-25 -

Contact:Liu Bin, Professor, Doctoral supervisor, College of Stomatology, Lanzhou University, Lanzhou 730000, Gansu Province, China liubkq@lzu.edu.cn -

About author:Si Qing-zong★, Studying for master’s degree, Lecturer, College of Stomatology, Lanzhou University, Lanzhou 730000, Gansu Province, China siqz@lzu.edu.cn

CLC Number:

Cite this article

Si Qing-zong, An Xiao-li, An Ying-fei, Liu Bin. Medical ultra-high molecular weight polyethylene modification and tribological characteristics[J]. Chinese Journal of Tissue Engineering Research, 2013, 17(3): 496-500.

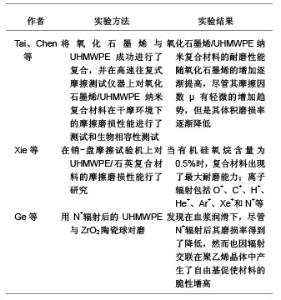

share this article

2.1 人工髋关节的组成 目前,人工髋关节的组成主要包括关节臼(UHMWPE、金属、陶瓷等)和关节头(金属、陶瓷等)。其中以UHMWPE为关节臼和以钴铬合金为股骨关节头的配副最为经典。但是,各种配副对偶又都有其自身明显的缺陷,如UHMWPE-金属,其致命的缺点是所产生的磨削以及由此导致的无菌松动而引起最终手术的失败[5];金属-金属,其磨损率很低[6],但受腐蚀后所产生的金属离子具有细胞毒性,易发生骨溶解等无法预测的不良后果等。 2.2 对UHMWPE的改性研究 目前对UHMWPE作为人工全髋关节材料的改性研究主要包括以下方面。 2.2.1 无机填料充填UHMWPE改性其耐磨性能 许多纳米级的粉末、纤维等具有自身良好的理化性能,应用这些物质作为充填材料与纯UHMWPE进行复合,制备出兼具各自优点的复合材料,如羟基磷灰石[7]、氧化锆[8]、炭黑[9]、碳纤维[10]、碳纳米管[11]、氧化铝等[12]。所制得复合材料耐磨性都得到了不同程度的提高,但复合材料的其他性能,如机械力学性能等却有所降低,过度交联导致的断裂等[13]。此外,另外一些诸如碳纳米管的充填材料相当昂贵,成本较高。而据Tai,Chen等[14-15]的最新报道,因氧化石墨烯具有非常低的摩擦因数μ,并且可以从价格低廉的高纯石墨制得,以及其一系列良好的理化性能,而将其与UHMWPE成功进行了复合,并在高速往复式摩擦测试仪器上对氧化石墨烯/UHMWPE纳米复合材料在干摩环境下的摩擦磨损性能进行了测试和生物相容性测试,实验结果显示,氧化石墨烯/ UHMWPE纳米复合材料的耐磨性能随氧化石墨烯的增加逐渐提高,尽管其摩擦因数μ有轻微的增加趋势,但是其体积磨损率逐渐降低[14]。同时根据MC3T3-E1成骨细胞在氧化石墨烯UHMWPE复合材料在上培养96 h后,对MC3T3-E1成骨细胞的增殖和黏附并没有发现明显的区别这一事实,证明其复合材料具有良好的生物相容性[15]。 UHMWPE的改性研究: "

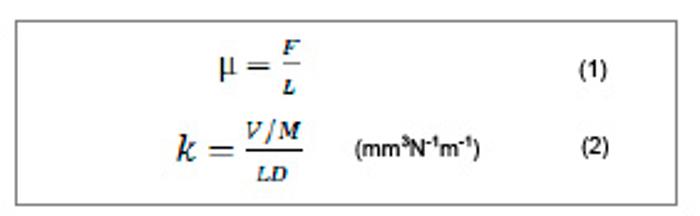

2.2.2 交联改性 有机硅氧烷偶联剂交联改性:Xie等[16]在销-盘摩擦试验机上对UHMWPE/石英复合材料的摩擦磨损性能行了研究,结果表明:当有机硅氧烷含量为0.5%时,复合材料出现了最大耐磨能力;离子辐射包括:O+、C+、H+、He+、Ar+、Xe+和N+等,其中Luo等[17]用N+辐射后的UHMWPE与ZrO2陶瓷球对磨。发现在血浆润滑下,尽管N+辐射后其磨损率得到了降低,然而也因辐射交联在聚乙烯晶体中产生了自由基促使材料的脆性增高。 2.3 摩擦磨损机制 Wang等[18]从理论原理与临床和实验室的实际出发,总结并概括出了UHMWPE在人工关节3个主要的摩擦磨损机制。 磨粒磨损:粗糙的硬质表面或接触界面内存在的硬质颗粒,切削聚合物材料而引起磨损的现象。这种磨损主要受硬质材料的表面性质、聚合物自身的机械性能以及环境因素等影响。对UHMWPE-金属摩擦副而言,当金属表面比较粗糙时,UHMWPE材料的磨损机制主要是磨粒磨损。黏附磨损:在UHMWPE材料表面与对磨面之间真实接触区域内,在界面上紧靠对磨面的一侧发生一侧材料微凸体断裂,并从其本体材料上撕裂下来,黏附在对磨面上,形成转移膜和依附膜,或形成自由磨屑。在其剪切强度较高的一方表面上形成薄膜,即转移膜。黏附磨损是UHMWPE的主要方式,特别是当对偶表面比较光滑时。 疲劳磨损:摩擦时UHMWPE材料表面受到周期性交变载荷,表面上部分微凸体相互作用,使接触区域产生很大变形和应力,在材料的表层和亚表层形成裂纹而导致UHMWPE材料损失或破坏的现象。这主要是由于材料自身结构的缺陷,导致在摩擦过程中产生的磨损破坏现象,尤其是在循环摩擦磨损过程中。 2.4 体外摩擦磨损研究 目前,大多数的实验研究都在体外进行,临床上多采用跟踪观察的手段。体外摩擦磨损研究总体上包括以下方面。 2.4.1 髋关节摩擦磨损模拟试验机 髋关节是一个球窝轴承式的运动关节,其主要动作可以分解为矢状面上的前屈后伸、冠状面上的内收外展以及横断面上的内外旋转3个方向上的运动[19]。因此,其模拟试验机的设计就显得极为复杂。目前,人工关节模拟机大致分为球-片/盘式、销-盘式、摆轴和多轴式。此外,Paul[20]研究了人在慢步、正常和快速行走时髋臼的受力情况,提出了著名的Paul载荷曲线。另外,关节模拟机一般在室内室温进行,为了模拟正常人体体温环境,Geringer 等[3]利用空调将室温控制在37 ℃左右以模拟体温环境。 2.4.2 润滑体系 人的天然髋关节有关节滑液及软骨的润滑保护作用,而人工髋关节置换后关节囊和软骨结构受到破坏,导致置换后润滑系统远不如天然关节的润滑系统,造成较高的磨损。为了降低人工关节的体外磨损,更真实地模拟生理性关节运动环境,(小/胎牛)血清、血浆、Hanks平衡盐溶液[21]、磷酸盐缓冲液,去离子水、生理盐水、透明质酸等均作为润滑剂广泛应用于关节的实验室摩擦磨损测试中[21-22]。并且,在摩擦测试过程中,通常在关节滑液中加入一定量的叠氮化钠以防止细菌生长繁殖影响实验结果。其中润滑剂的作用有防腐防锈,控制烧伤,降低、均匀局部温度,清洁疏散磨削,密闭,缓和冲击和均匀载荷等。2.4.3 体外模拟测试的表征及评价方法 在人工髋关节的体外摩擦磨损模拟测试过程中,对其进行的实时监测和后期形貌等表征,都是实验结果的重要指标。包括:摩擦测试过程中的摩擦因数μ [14],磨损率K [23],表面形貌以及磨削等。 在公式(1)、(2)中:F是摩擦力,L是所加载的载荷;两者的单位都是N;V是体积,M是质量,D是摩擦测试中整个过程滑行的距离,后三者的单位分别是mm3、g和m。其中,磨损率包括体积磨损率和质量磨损率,在有润滑液润滑环境下,后者比前者因材料吸水等原因其实验误差相对较大[24];摩擦因数μ与磨损率K之间没有直接的正比关系,甚至有时恰恰成反比[25]。Gladkis等[26]利用原子力显微镜观察了UHMWPE作为膝关节摩擦磨损后的磨削,提出了常见的4种磨削形貌(瘦长纤维状,矮短瘦形,圆形,瘦长折叠形)。"

| [1] Ohta M,Hyon SH,Tsutumi S.Control of crystalline orientation to enhance the wear resistance of ultra-high molecular weight polyethylene crystallization cups for artificial joints.Wear.2003; 255:1045-1050.[2] Jacobs JJ.The UHMWPE Handbook.Ultra-High Molecular Weight Polyethylene in Total Joint Replacement.J Bone Joint Surg (Am).2005;87:1906-1906.[3] Geringer J,Witold T,Rouchouse G.Wear behavior of PAEK, poly(aryl-ether-ketone), under physiological conditions, outlooks for performing these materials in the field of hip prosthesis.Wear.2011;271:2793-2803.[4] Burger NDL,DeVaal PL,Meyer JP.Failure analysis on retrieved ultra high molecular weight polyethylene (UHMWPE) acetabular cups.Eng Fail Anal.2007;14:1329-1345.[5] Kobayashi A,Bonfield W,Kadoya Y,et al.The size and shape of particulate polyethylene wear debris in total joint replacements. Proceedings of the Institution of Mechanical Engineers, Part H: Journal of Engineering in Medicine, 1997; 211(1):11-15.[6] Learmonth ID,Young C,Rorabeck C.The operation of the century: total hip replacement. Lancet.2007;370:1508-1519.[7] Xiong L,Xiong DS,Jin JB.Study on Tribological Properties of Irradiated Crosslinking UHMWPE Nano-Composite. J Bionic Eng.2009;6(1):7-13.[8] Plumlee K,Schwartz CJ.Improved wear resistance of orthopaedic UHMWPE by reinforcement with zirconium particles.Wear.2009;267(5-8):710-717.[9] He CX,Shi LP.Tribology property of uhmwpe composites filled with carbon black and tiny glass powder.Mater Sci Technol. 2005;13(14):387-389.[10] Xiong DS. Friction and wear properties of UHMWPE composites reinforced with carbon fiber.Mater Lett.2005; 59 (2-3):175-179.[11] Zoo YS,An JW,Lim DP,et al.Effect of carbon nanotube addition on tribological behavior of UHMWPE.Tribol Lett.2004; 16(4):305-309.[12] Roy S,Pal S.Characterization of silane coated hollow sphere alumina-reinforced ultra high molecular weight polyethylene composite as a possible bone substitute material.Bull Mat Sci.2002;25:609-612.[13] Bradford L,Baker DA,Graham J,et al.Wear and surface cracking in early retrieved highly cross-linked polyethylene acetabular liners. J Bone Joint Surg Am.2004;86:1271-1282.[14] Tai ZX,Chen YF,An YF,et al.Tribological Behavior of UHMWPE Reinforced with Graphene Oxide Nanosheets. Tribol Lett.2012;46:55-63.[15] Chen YF,Qi YY,Tai ZX,et al.Preparation, mechanical properties and biocompatibility of graphene oxide/ultrahigh molecular weight polyethylene composites.Eur Polymer J.2012; 10.1016/j.eurpolymj.2012.03.011.[16] Xie XL,Tang CY,Chan KYY,et al.Wear performance of ultrahigh molecular weight polyethylene/quartz composites. Biomaterials.2003;24:1889-1896.[17] Luo Y,Ge SR.Load dependence of nanohardness in nitrogen ion implanted Ti6Al4V alloy and fractal characterization.J China Univ Min Tech.2007;17:363-367.[18] Wang A,Essner A,Polineni VK,et al.Lubrication and wear of ultra-high molecular weight polyethylene in total joint replacements.Tribol Int.1998;31:17-33.[19] 黄捷,杨丹,屈树新.超高分子量聚乙烯在人工髋关节中的摩擦磨损研究[J].材料导报,2011,25(3):136-140.[20] Paul JP.Force actions transmitted by joints in the human body. Proc R Soc Lond B Biol Sci.1976;192(1107):163-172.[21] Gispert MP,Serro AP,Colaco R,et al.Friction and wear mechanisms in hip prosthesis: Comparison of joint materials behaviour in several lubricants.Wear. 2006;260:149-158.[22] Waters EPJ,Spedding PL,Dohert AP,et al.Wear of the artificial hip joint material under lubrication. Asia Pac J Chem Eng. 2009; 4:80-89.[23] Park HJ,Kwak SY,Kwak S.Wear-Resistant Ultra High Molecular Weight Polyethylene/Zirconia Composites Prepared by in situ Ziegler-Natta Polymerization.Macromol Chem Phys.2005;206:945-950.[24] Yao J,Laurent MP,Gilbertson LN,et al.The effect of minimum load on the fluid uptake and wear of highly crosslinked UHMWPE total hip acetabular components.Wear.2001;250: 140-144.[25] Samad MA,Sinha SK. Dry sliding and boundary lubrication performance of a UHMWPE/CNTs nanocomposite coating on steel substrates at elevated temperatures.Wear.2011;270: 395-402.[26] Gladkis LG,Timmers H,Scarvell JM,et al. Detailed three-dimensional size and shape characterisation of UHMWPE wear debris.Wear.2011;270:455-463. |

| [1] | Yu Shiyu, Yu Sutong, Xu Yang, Zhen Xiangyan, Han Fengxuan. Advances in research and application of tissue engineering therapeutic strategies in oral submucous fibrosis [J]. Chinese Journal of Tissue Engineering Research, 2026, 30(4): 936-948. |

| [2] | Yang Hu, Zheng Yu, Jia Chengming, Wang Tong, Zhang Guangfei, Ji Yaoyao. Immune microenvironment regulates bone regeneration [J]. Chinese Journal of Tissue Engineering Research, 2026, 30(3): 701-710. |

| [3] | Xu Wenhe, Li Xiaobing, Liu Fang. Functionalized biomimetic mineralized collagen modified orthopedic implants [J]. Chinese Journal of Tissue Engineering Research, 2026, 30(2): 516-527. |

| [4] | Shui Jing, He Yu, Jiang Nan, Xu Kun, Song Lijuan, Ding Zhibin, Ma Cungen, Li Xinyi. Astrocytes regulate remyelination in central nervous system [J]. Chinese Journal of Tissue Engineering Research, 2025, 29(36): 7889-7897. |

| [5] | Yu Lei, Zhang Wei, Qin Yi, Ge Gaoran, Bai Jiaxiang, Geng Dechun. Repair of femoral condyle defects using mesoporous bioactive glass grafted with bone morphogenetic protein 2 osteogenic peptide inspired by mussel [J]. Chinese Journal of Tissue Engineering Research, 2025, 29(22): 4629-4638. |

| [6] | Wu Zhixin, Jiang Wenwen, Zhan Jianhui, Li Yangshurun, Ren Wenyan, Wang Yiyu. Hydrogels: role and problems in the repair of oral and maxillofacial defects [J]. Chinese Journal of Tissue Engineering Research, 2025, 29(10): 2178-2188. |

| [7] | Jiang Haifang, Liu Rong, Hu Peng, Chen Wei, Wei Zairong, Yang Chenglan, Nie Kaiyu. Application of 3D printing technology in the precise and personalized treatment of cleft lip and palate [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(3): 413-419. |

| [8] | Yang Feng, Zhao Qian, Zhang Shixuan, Zhao Tienan, Feng Bo. Effectiveness and safety of rapamycin combined with CD133 antibody stent in preventing vascular restenosis [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(4): 579-584. |

| [9] | Zhang Tong, Cai Jinchi, Yuan Zhifa, Zhao Haiyan, Han Xingwen, Wang Wenji. Hyaluronic acid-based composite hydrogel in cartilage injury caused by osteoarthritis: application and mechanism [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(4): 617-625. |

| [10] | Zhao Xingchang, Song Shiqiang, He Feng, Tang Yujin, Liu Jia. Application of biomaterial scaffolds in the treatment of spinal cord injury [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(28): 4562-4568. |

| [11] | Liu Kang, Wang Yongping, Zuo Kebin, Yang Haitao, Jia Bin. Polydatin loaded collagen/heparin sulfate scaffold in the treatment of spinal cord injury in rats [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(28): 4500-4506. |

| [12] | Yun Xiao, Ding Tong, Yang Weiqiang, Guo Xinjun. Nano hydroxyapatite/chitosan scaffold loaded with Akebia saponin D in bone defect repair [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(27): 4293-4299. |

| [13] | Hu Qiuyu, Yang Long, Yang Yong, Song Shenchao. Aligned poly(butylene adipate-co-terephthalate)/type I collagen fibers promote tendon-bone healing after anterior cruciate ligament rupture [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(27): 4314-4319. |

| [14] | Liu Liang, Hu Gaoquan, Wei Zhao, Chen Lin, Hong Feng. Potential of bacterial nanocellulose/polydopamine composite tubes as small-diameter artificial blood vessel [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(22): 3535-3542. |

| [15] | Guo Yangyan, Yu Zhengwen, Zhang Jian. Research hotspots of magnesium alloy biomaterials in an in vivo animal [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(22): 3556-3565. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||