[1] 蒋伟,许胜,周亚男.选择性激光熔覆技术成形质量影响因素及其在口腔修复体制造中的应用进展[J].山东医药,2019,59(17):109-112.

[2] 张洁.老年天然牙与三种口腔修复材料摩擦磨损学性能的实验研究[J].口腔医学研究,2019,35(3):254-257.

[3] 崔丹,刘逵仲,张兆钰,等.二氧化锆与钴铬合金修复体精细抛光后对天然牙磨耗的影响[J].口腔医学,2018,38(1):10-14,77.

[4] 常维巍,杨洪涛.两种不同工艺制作的钛金属冠临床效果研究[J].全科口腔医学电子杂志,2018,5(22):106,108.

[5] 赵会懂,张玉杰,焦晓燕,等.3D打印技术在口腔修复治疗中的应用进展[J].临床误诊误治,2019,32(10):113-116.

[6] 李皓鹏,周亚男,魏维,等.3D打印用CoCrWMo合金粉末的研制及性能分析[J].特钢技术,2018,24(2):10-15,47.

[7] 李妍熹,姚洋.3D打印技术在口腔修复体直接制作中的应用[J].临床口腔医学杂志,2018,34(6):371-375.

[8] 戴宜君,董研,彭伟,等.SLM打印钴铬合金基底冠精度及密合性研究[J].实用口腔医学杂志,2018,34(2):158-163.

[9] 刘一帆,王伟娜,于海,等.选择性激光熔覆(SLM)钛合金可摘局部义齿支架的适合性研究[J].实用口腔医学杂志,2017,33(3): 302-305.

[10] 许卫星,袁剑鸣,唐颖,等.激光钴铬基底冠与铸造钴铬合金基底冠的边缘密合度比较[J].上海交通大学学报(医学版),2016,36(10): 1478-1481.

[11] 叶荣荣,贾爽.选择性激光熔覆技术与失蜡铸造法制作的金属嵌体边缘微渗漏的对比研究[J].中国美容医学,2016,25(8):70-72.

[12] WEI W, ZHOU Y, LIU W, et al. Microstructural characterization, mechanical properties, and corrosion resistance of dental Co-Cr-Mo-W alloys manufactured by selective laser melting. J Mater Eng Perform. 2018;27(10):5312-5320.

[13] 刘莉,李波,虞永芳.2种方法制作金属基底冠边缘适合性和金瓷结合力比较[J].上海口腔医学,2019,28(6):597-600.

[14] 邹珊珊,姜迎春,时之凯.生物激光烤瓷冠与传统钴铬烤瓷冠在固定修复中的应用比较[J].解放军预防医学杂志,2019,37(5):111-112.

[15] LI J, CHEN C, LIAO J, et al. Bond strengths of porcelain to cobalt-chromium alloys made by casting, milling, and selective laser melting.J Prosthet Dent.2017;118(1):69-75.

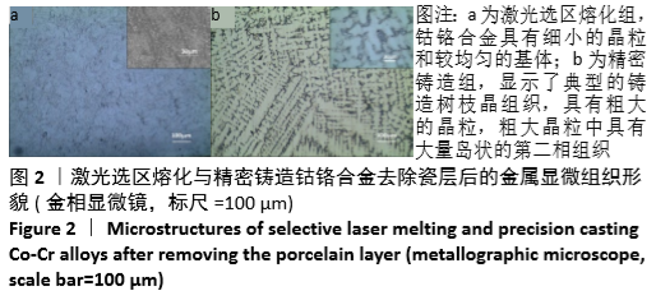

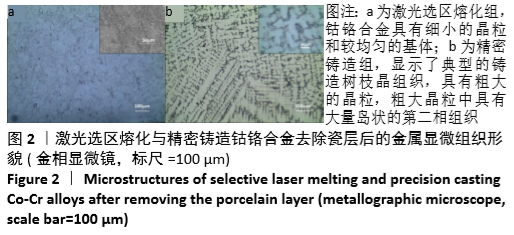

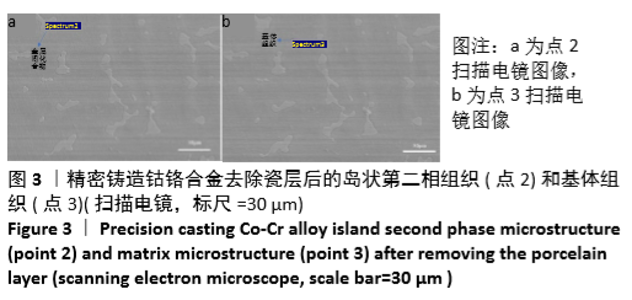

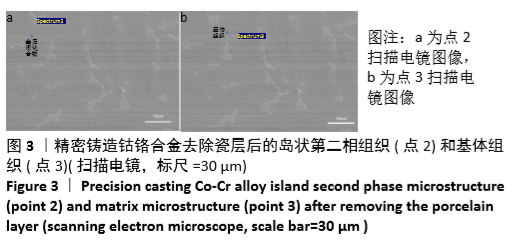

[16] ZHOU Y, WEI W, YAN J, et al. Microstructures and metal-ceramic bond properties of Co-Cr biomedical alloys fabricated by selective laser melting and casting.Mat Sci Eng A-Struct. 2019;759:594-602.

[17] 石云鹤,朱洪水.选择性激光熔覆技术用于口腔临床的研究进展[J].口腔材料器械杂志,2017,26(4):218-221.

[18] 苑翔,邓巍,张辉,等.选择性激光熔覆钴铬合金烤瓷冠对牙周组织的影响[J].中国激光医学杂志,2019,28(1):42-45.

[19] 芮孟瑜,何柳青,吴梓谦,等.三种钴基口腔修复体合金在与茶饮品作用下钴离子析出的比较[J].中国金属通报,2018(7):287-289.

[20] 向秋叙,王璐,谭发兵.SLM国产CoCr合金机械性能和金瓷结合强度的研究[J].第三军医大学学报,2019,41(5):502-507.

[21] ZHOU Y, LI N, YAN J, et al. Comparative analysis of the microstructures and mechanical properties of Co-Cr dental alloys fabricated by different methods.J Prosthet Dent. 2018;120(4):617-623.

[22] XIN X, XIANG N, CHEN J, et al. In vitro biocompatibility of Co-Cr alloy fabricated by selective laser melting or traditional casting techniques.Mater Lett.2012;88:101-103.

[23] 喻茜茜,郭菁,朱洪水.不同喷砂条件对选择性激光熔覆钴铬合金金瓷结合强度影响的研究[J].华西口腔医学杂志,2018,36(5): 539-543.

[24] 王晓洁,郭天文.金瓷结合强度的测试方法[J].口腔材料器械杂志, 2004(1):32-34+46.

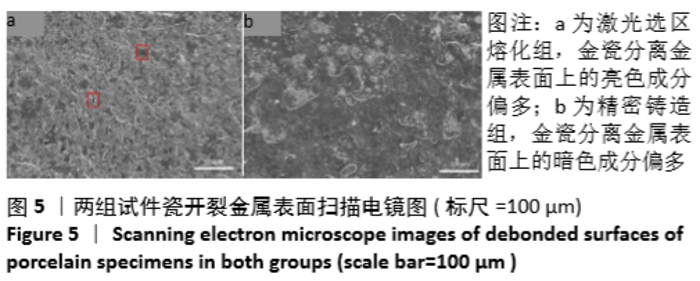

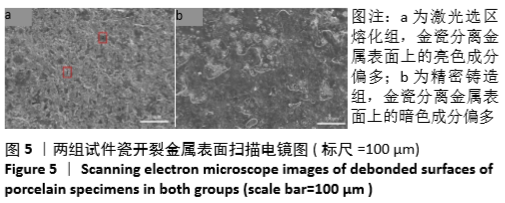

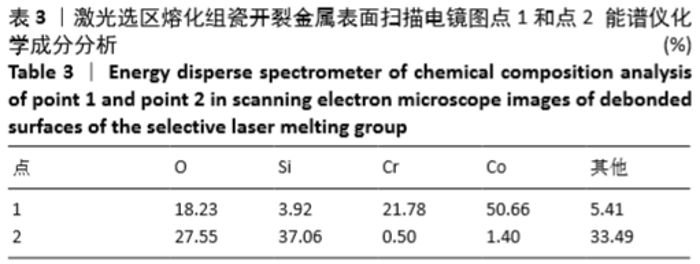

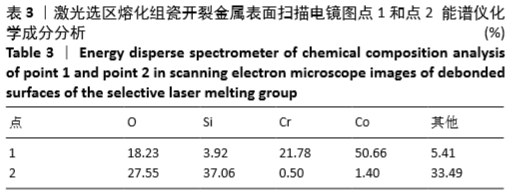

[25] 周亚男,魏维,颜家振,等.激光选区熔覆牙科用钴铬钼合金的金瓷结合性研究[J].工程科学与技术,2018,50(2):220-225.

[26] 李洁银,李瑞男,刘朗,等.铸造和切削钴铬合金与瓷结合强度的比较[J].中华口腔医学研究杂志(电子版),2016,10(1):45-50.

[27] WU Y, MOSER J, JAMESON L, et al. The effect of oxidation heat treatment of porcelain bond strength in selected base metal alloys.J Prosthet Dent.1991;66:439-44.

[28] 吴芝凯,李宁.牙科Co-Cr烤瓷合金的金瓷结合性研究[J].特种铸造及有色合金,2011,31(2):164-166,204.

[29] 王兵,宋昕,彭练,等.选择性激光烧结工艺制备的钴铬合金的微观结构[J].中国材料进展,2017,36(Z1):594-598.

[30] 黄乾尧.高温合金-特殊钢丛书[M].北京:冶金工业出版社, 2000: 107-108. |