Chinese Journal of Tissue Engineering Research ›› 2019, Vol. 23 ›› Issue (34): 5497-5502.doi: 10.3969/j.issn.2095-4344.1936

Previous Articles Next Articles

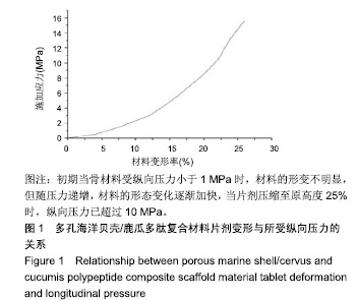

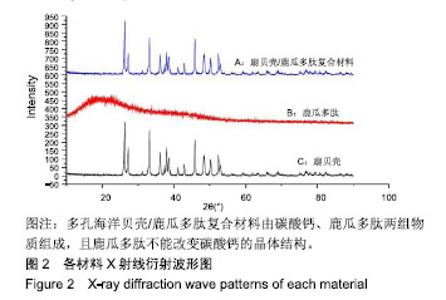

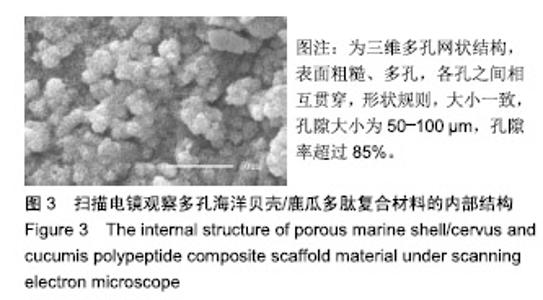

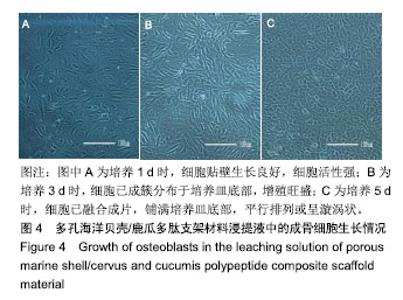

Biocompatibility of 3D printed three-dimensional porous marine shell/cervus and cucumis polypeptide composite scaffold material

- Department of Orthopedics, Shanghai Eastern Hepatobiliary Surgery Hospital, Shanghai 200438, China

-

Received:2019-06-20Online:2019-12-08Published:2019-12-08 -

About author:Lou Yi, Master, Attending physician, Department of Orthopedics, Shanghai Eastern Hepatobiliary Surgery Hospital, Shanghai 200438, China -

Supported by:The Youth Fund of Shanghai Commission of Health and Family Planning, No. 20164Y0158 (to LY)

CLC Number:

Cite this article

Lou Yi, Zhang Zhiwen. Biocompatibility of 3D printed three-dimensional porous marine shell/cervus and cucumis polypeptide composite scaffold material[J]. Chinese Journal of Tissue Engineering Research, 2019, 23(34): 5497-5502.

share this article

| [1]殷建,王斌,朱超,等.局部注射促血管生成素2调控自噬促进体内组织工程人工骨早期血管化和骨缺损修复的研究[J].中国修复重建外科杂志,2018, 32(9):1150-1156. [2]王韦丹,韩军杰,万鹏,等.可降解镁合金作为骨填充材料的研究和展望[J].中国医疗设备,2015,30(9):12-15. [3]Thi HN,Chan KH,Dai HN,etal.Biocompatibility of PCL/PLGABCP porous scaffold for bone tissue engineering applications.Biomater Sci Polym Ed.2017;28(9):864-878. [4]Titorencu I,Albu MG,Nemecz M,et al.Natural Polymer-Cell Bioconstructs for Bone Tissue Engineering.Curr Stem Cell Res Ther. 2017;12(2):165-174. [5]毛文文,茹江英.羟基磷灰石类陶瓷在骨组织工程中的研究与更广泛应用[J].中国组织工程研究,2018,22(30):4855-4863.[6]Nyberg E,Holmes C,Witham T,et al.Growth factor-eluting technologies for bone tissue engineering.Drug Deliv Transl Res.2016;6(2):184-194. [7]邢科,程高建,黄桂林.医用硫酸钙人工骨颗粒在病理性骨折及骨缺损治疗中的应用[J].美中国际创伤杂志,2016,15(37):62-67. [8]贺钧,李自良,谢志钢.骨替代材料的骨诱导性能研究进展[J].口腔疾病防治, 2018,26(2):124-127.[9]侯洋,史建刚,袁文.纳米羟基磷灰石/甲基丙烯酸2-羟基乙酯人工骨支架的制备及其功能评价[J].中国矫形外科杂志, 2018,26(5):441-447 [10]郑荣桥,何星.三维打印材料在骨组织工程中的研究进展[J].广东化工, 2018,45(7):151-152. [11]Tsuruga E,Takita H,Itoh H,et al.Pore size of porous hydroxyapatite as the cell-substratum controls BMP-induced osteogenesis.J Biochem (Tokyo).1997;121(2):317-324. [12]韩义忠,崔正阳,陈岑,等.以贻贝贝壳为原料制备的无定形磷酸钙及其性质[J].浙江理工大学学报,2016,35(6):849-854. [13]谭亚运,张民.硅酸盐/磷酸盐复合型骨水泥的研究现状及新进展[J].中华临床医师杂志,2017,11(13):1993-1996. [14]张晓庆,秦建华,刘慧.透明质酸-明胶-纳米羟基磷灰石仿生骨支架的制备及成骨活性研究[J].高校化学工程学报, 2017,31(2):387-393.[15]Guarino V,Ambrosio L.Temperature-driven,processing techniques for manufacturing fully interconnected porous scaffolds in bone tissue engineering.Proc Inst Mech Eng H. 2010;224(12):1389-1400. [16]Jang JH,Castano O,Kim HW.Electrospun materials as potential platforms for bone tissue engineering. Adv Drug Deliv Rev.2009;61(12):1065-1083. [17]张迪峰,余霄,庞清江.骨组织工程支架及骨修补材料:复合型骨移植材料的前景更好[J].中国组织工程研究, 2018,22(26):4253-4258. [18]常跃文,张长青,曾炳芳.骨组织工程学中的复合支架材料的研究现状和进展[J].口腔材料器械杂志,2005,14(1):24-28. [19]齐晗,张东霞,曹国琴,等.骨髓间充质干细胞复合支架材料的骨组织工程研究进展[J].生物医学进展,2018,44(4):794-796. [20]耿燕丽,阮孜炜,李东旭.骨组织工程支架材料的研究进展[J].材料导报, 2004, 18(11):9-12. [21]Reichert JC,Epari DR,Wullschleger ME,et al.Establishment of a preclinical ovine model fortibial segmental bone defect repair by applying bone tissueengineering strategies.Tissue EngPart B Rev. 2010;16(1):93-104. [22]Bakker AD,Schrooten J,van Cleynenbreugel T,et al.Quantitative screening of engineered implants in a long bone defect model in rabbits.Tissue Eng Part C Methods. 2008;14(3):251-260. [23]代银平,王雪莹,叶炜宗,等.贝壳废弃物的资源化利用研究[J].资源开发与市场, 2017,33(2):203-208.[24]吴晓光,鹿瓜多肽对骨质疏松性骨折术后骨生长过程中炎症因子影响研究[J].辽宁中医药大学学报,2018,20(1):170-172. [25]管义红,周瑞明.中药熏蒸联合鹿瓜多肽治疗老年急性膝骨关节炎患者的临床研究[J].中国中医急症,2018,27(6):982-985. [26]胡熙耀,玉芳,陈德森.鹿瓜多肽穴位注射治疗兔椎体骨折[J].中国中西医结合外科杂志,2018,24(5):603-608.[27]Obregon F,Vaquette C,Ivanovski S,et al.Three-Dimensional Bioprinting for Regenerative Dentistry and Craniofacial Tissue Engineering.J Dent Res. 2015;94(9):143-152. [28]Yao Q,Wei B,Guo Y,et al.Design, construction and mechanical testing of digital 3D anatomical data-based PCL–HA bone tissue engineering scaffold.J Mater Sci Mater Med.2015;26(1):5360. [29]Cox SC,Thornby JA,Gibbons GJ,et al.3D printing of porous hydroxyapatite scaffolds intended for use in bone tissue engineering applications.Mater Sci Eng C.2015;47:237-247.[30]Luo Y,Lode A,Wu C,etal.Alginate/Nanohydroxyapatite Scaffolds with Designed Core/Shell Structures Fabricated by 3D Plotting and in Situ Mineralization for Bone Tissue Engineering.Acs Appl Mater Int. 2015; 7(12):6541-6549. [31]陈江,旭晞,周麟.骨免疫调节机制对种植体骨结合及骨生物材料引导骨再生的影响[J].口腔疾病防治,2018,26(10):613-620.[32]Liu Z,Yuan X,Liu M,et al.Antimicrobial peptide combined with BMP2-modified mesenchymal stem cells promotes calvarial repair in an osteolytic model.Mol Ther.2018;26(1):199-207. [33]Kobayashi N,Hashimoto Y,Otaka A,et al.Porous alphatricalcium phosphate with immobilized basic fibroblast growth factor enhances bone regeneration in a canine mandibular bone defect model. Materials(Basel).2016;9(10):E853-860. [34]Matsushima A,Kotobuki N,Tadokoro M,et al.In vivo osteogenic capability of human mesenchymal cells cultured on hydroxyapatite and on beta-tricalcium phosphate.Artif Organs.2009;33(6):474-481. [35]Kang SW,Lee JS,Park MS,et al.Enhancement of in vivo bone regenerati-on efficacy of human mesenchymal stem cells.J Microbiol Biotechnol.2008;18(5):975-982. [36]Granero-Molto F,Weis JA,Longobardi L,et al.Role of mesenchymal stem cells in regenerative medicine: application to bone and cartilage repair.Expert Opin Biol Ther. 2008;8(3):255-268. [37]Mendes SC,Tibbe JM,Veenhof M,et al.Relation between in vitro and in vivo osteogenic potential of cultured human bone marrow stromal cells.J Mater Sci Mater Med. 2004;15(10):1123-1128. [38]Arinzeh TL,Peter SJ,Archambault MP,et al.Allogeneic mesenchymal stem cells regenerate bone in a critical-sized canine segmental defect.J Bone Joint Surg Am. 2003;85-A(10):1927-1935. [39]Chen L,Tredget EE,Wu PY,et al.Paracrine factors of mesenchymal stem cells recruit macrophages and endothelial lineage cells and enhance wound healing.PLoS One. 2008;3(4):e1886-1891.[40]Stolzing A,Jones E,McGonagle D,et al Age-related changes in human bone marrow-derived mesenchymal stem cells: consequences for cell therapies.Mech Ageing Dev. 2008;129(3):163-173. [41]Kimmerling KA,Furman BD,Mangiapani DS,et al.Sustained intra-articular delivery of IL-1RA from a thermally-responsive elastin-like polypeptide as a therapy for post-traumatic arthritis.Eur Cell Mater. 2015;29: 124-139. |

| [1] | Lu Dezhi, Mei Zhao, Li Xianglei, Wang Caiping, Sun Xin, Wang Xiaowen, Wang Jinwu. Digital design and effect evaluation of three-dimensional printing scoliosis orthosis [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(9): 1329-1334. |

| [2] | Zhang Tongtong, Wang Zhonghua, Wen Jie, Song Yuxin, Liu Lin. Application of three-dimensional printing model in surgical resection and reconstruction of cervical tumor [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(9): 1335-1339. |

| [3] | Liu Zhengpeng, Wang Yahui, Zhang Yilong, Ming Ying, Sun Zhijie, Sun He. Application of 3D printed interbody fusion cage for cervical spondylosis of spinal cord type: half-year follow-up of recovery of cervical curvature and intervertebral height [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(6): 849-853. |

| [4] | Hua Haotian, Zhao Wenyu, Zhang Lei, Bai Wenbo, Wang Xinwei. Meta-analysis of clinical efficacy and safety of antibiotic artificial bone in the treatment of chronic osteomyelitis [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(6): 970-976. |

| [5] | Zhang Bin, Sun Lihua, Zhang Junhua, Liu Yusan, Cui Caiyun. A modified flap immediate implant is beneficial to soft tissue reconstruction in maxillary aesthetic area [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(5): 707-712. |

| [6] | Xu Junma, Yu Yuechao, Liu Zhi, Liu Yu, Wang Feitong. Application of 3D-printed coplanar template combined with fixed needle technique in percutaneous accurate biopsy of small pulmonary nodules [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(5): 761-764. |

| [7] | Li Chenjie, Lü Linwei, Song Yang, Liu Jingna, Zhang Chunqiu. Measurement and statistical analysis of trabecular morphological parameters of titanium alloy peri-prosthesis under preload [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 516-520. |

| [8] | Wu Zijian, Hu Zhaoduan, Xie Youqiong, Wang Feng, Li Jia, Li Bocun, Cai Guowei, Peng Rui. Three-dimensional printing technology and bone tissue engineering research: literature metrology and visual analysis of research hotspots [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 564-569. |

| [9] | Li Xiaozhuang, Duan Hao, Wang Weizhou, Tang Zhihong, Wang Yanghao, He Fei. Application of bone tissue engineering materials in the treatment of bone defect diseases in vivo [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 626-631. |

| [10] | He Jie, Chang Qi. Biological reconstruction of large bone defects after resection of malignant tumor of extremities [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(3): 420-425. |

| [11] | Xing Hao, Zhang Yonghong, Wang Dong. Advantages and disadvantages of repairing large-segment bone defect [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(3): 426-430. |

| [12] | Huang Youyi, Yuan Wei. Application of 3D printing technology in fracture and deformity of foot and ankle [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(3): 438-442. |

| [13] | Wei Congcong, Yao Mengxuan, Yang Meng, Li Huijie. Mechanism and treatment of osteolysis around artificial joint prosthesis [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(27): 4401-4407. |

| [14] | Zheng Feng, Zhang Fucai, Xu Zhe. MicroRNA-98-5p promotes osteoblast proliferation and differentiation: possibilities and mechanisms [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(26): 4112-4117. |

| [15] | Wang Qiufei, Gu Ye, Peng Yuqin, Xue Feng, Ju Rong, Zhu Feng, Wang Yijun, Geng Dechun, Xu Yaozeng. Effect of Wnt/beta-catenin signaling pathway on osteoblasts under the action of wear particles [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(24): 3894-3901. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||