Chinese Journal of Tissue Engineering Research ›› 2024, Vol. 28 ›› Issue (3): 398-403.doi: 10.12307/2023.977

Previous Articles Next Articles

3D printing process of gelatin/oxidized nanocellulose skin scaffold with high elastic modulus and high porosity

Xu Xiaodong1, 2, Zhou Jiping3, Zhang Qi3, Feng Chen1, 2, Zhu Mianshun1, Shi Hongcan4

- 1Yangzhou Polytechnic Institute, Yangzhou 225127, Jiangsu Province, China; 2Jiangsu Province Engineering Research Center of Intelligent Application for Advanced Plastic Forming, Yangzhou 225127, Jiangsu Province, China; 3College of Mechanical Engineering, Yangzhou University, Yangzhou 225127, Jiangsu Province, China; 4Medical College, Yangzhou University, Yangzhou 225009, Jiangsu Province, China

-

Received:2022-11-21Accepted:2023-01-18Online:2024-01-28Published:2023-07-10 -

Contact:Zhou Jiping, MD, Professor, Doctoral supervisor, College of Mechanical Engineering, Yangzhou University, Yangzhou 225127, Jiangsu Province, China -

About author:Xu Xiaodong, MD, Lecturer, Yangzhou Polytechnic Institute, Yangzhou 225127, Jiangsu Province, China; Jiangsu Province Engineering Research Center of Intelligent Application for Advanced Plastic Forming, Yangzhou 225127, Jiangsu Province, China -

Supported by:National Natural Science Foundation of China, No. 81770018 (to SHC); Yangzhou-Yangzhou University Science and Technology Cooperation Project, No. SCX2017020015 (to ZJP); Basic Science (Natural Science) Research Project of Institutions of Higher Learning in Jiangsu Province, No. 21KJD460010 (to XXD); 2021 University-Level Scientific Research Topic (Natural Science) Project, No. 2021xjzk003 (to XXD)

CLC Number:

Cite this article

Xu Xiaodong, Zhou Jiping, Zhang Qi, Feng Chen, Zhu Mianshun, Shi Hongcan. 3D printing process of gelatin/oxidized nanocellulose skin scaffold with high elastic modulus and high porosity [J]. Chinese Journal of Tissue Engineering Research, 2024, 28(3): 398-403.

share this article

Add to citation manager EndNote|Reference Manager|ProCite|BibTeX|RefWorks

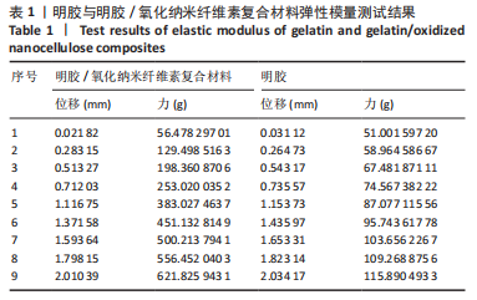

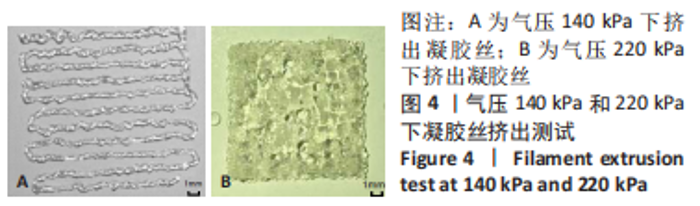

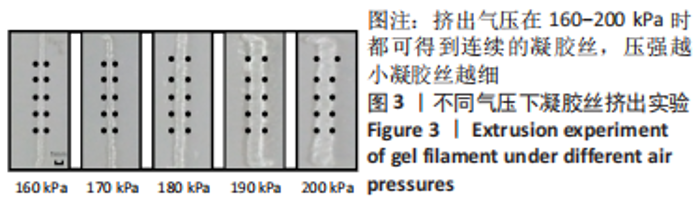

根据测量结果,可以根据弹性模量的计算公式计算明胶/氧化纳米纤维素样品和5%明胶样品的弹性模量,计算得到5%明胶样品的弹性模量为41 469 Pa,与产品标定的弹性模量相差不到1%,而明胶/氧化纳米纤维素复合材料样品的弹性模量为366 752 Pa,相比较5%明胶样品提升了约8.84倍。 2.2 明胶/氧化纳米纤维素皮肤支架及扫描电镜观测 为了观察明胶/氧化纳米纤维素皮肤支架的成型过程及最终得到的微观多孔结构,使用高分辨率的数码相机Canon EOS 80D记录了支架堆积成型的全过程,打印过程中支架的打印分辨率受到单根胶丝打印精度和堆叠方法的影响。图3显示了不同气压下挤出得到的凝胶丝形态,在使用明胶/氧化纳米纤维素复合凝胶进行支架3D打印的过程中,挤出气压在160-200 kPa时都可得到连续的凝胶丝,压强越小凝胶丝越细,在气压160 kPa时凝胶丝直径约1 mm,压强越大凝凝胶丝越粗,在气压200 kPa时凝胶丝直径约2.4 mm。其中越细的凝胶丝直径可以得到打印分辨率更高的三维多孔支架,但气压过小会导致胶丝挤出不流畅,从而出现欠搭接的现象,如图4A所示,气压选择140 kPa时挤出的胶丝无法顺利挤出,凝胶在喷嘴处形成小型凝胶球,导致制备的胶丝无法呈现直线状态;而当气压过大时会导致过堆积现象的出现,如图4B所示,当挤出气压220 kPa时打印得到的凝胶丝堆积在一起,无法得到可靠的三维多孔结构。"

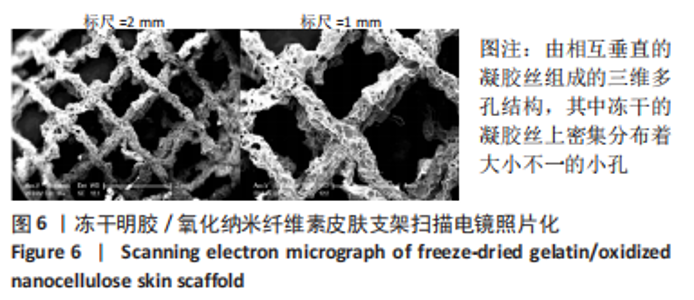

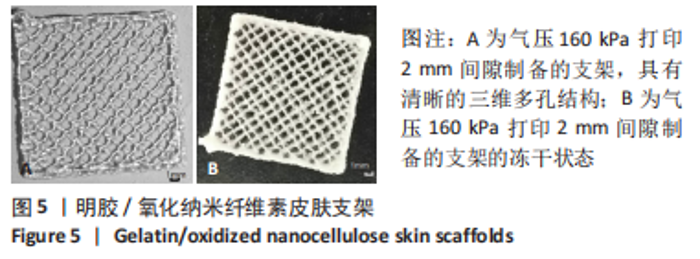

针对制备的复合凝胶,使用1.4.3中的打印参数,可以在挤出气压160 kPa时得到打印分辨率相对较高的三维多孔支架,图5A所示是在160 kPa下按照填充间隙2 mm打印得到的三维支架,图中可以看出刚打印得到的支架在饱含水分的状态下具有清晰的三维多孔结构。在将支架冻干脱水,得到如图5B所示的冻干支架,在扫描电镜下观测支架的微观形态,如图6所示,在图中可以清晰地看到由相互垂直的凝胶丝组成的三维多孔结构,其中冻干的凝胶丝上密集分布着大小不一的小孔,这些小孔可以为皮肤细胞的黏附提供便利,同时在凝胶丝之间存在边长约1 mm的方孔,这些方孔在临床上可以为营养液的浸润和代谢物的排出提供三维支撑,这与预期的三维结构一致。"

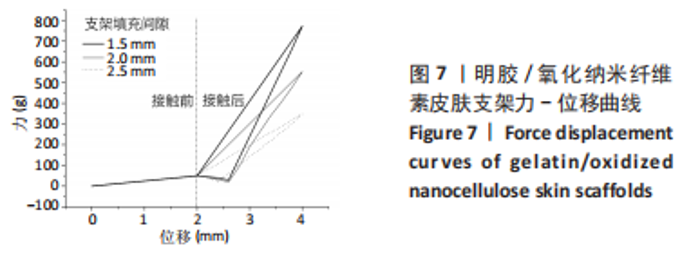

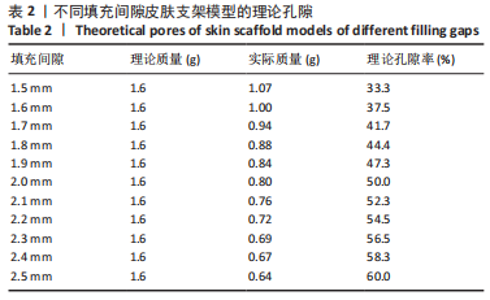

从图7中可以看出,打印支架时选择的填充间隙会影响支架的力学强度,对于填充间隙1.5 mm的明胶/氧化纳米纤维素支架,需要约770 g(即7.55 N)的作用力可以使其变形2 mm,即相对5 mm的高度变形40%;对于填充间隙2 mm的支架,相对变形40%需要550 g(即5.39 N)的作用力;填充间隙的增加使得支架的力学性能降低,对于2.5 mm填充间隙的支架,相对变形40%只需要平均348 g(即3.41 N)的作用力。与明胶/氧化纳米纤维素浇筑实心样本相比较,三维多孔结构会降低支架的抗压性能,1.5,2和2.5 mm的填充间隙分别使支架抗压性能降低了约30%,51%和71%。 从图7中还可以看出压头在上行的过程中其应力同样存在变化,原因是明胶/氧化纳米纤维素凝胶存在黏弹性,在压头上行的过程中支架也在上行,在此期间压头受到支架垂直向下作用力的影响,图中可以看出各支架在受压后的回弹情况,1.5 mm填充间隙的支架大约可以回弹1.4 mm的高度,相较2 mm的总变形回弹了约70%,2,2.5 mm填充间隙支架的回弹情况类似,都可以实现大约70%的回弹。据此可以得到结论,支架的抗压性能与支架的填充间隙密切相关,而黏弹性与支架的材料有关,与填充间隙关联不大。 2.4 皮肤支架孔隙率计算 从上面皮肤支架扫描电镜图片中可以看出,支架上的孔具有不同的直径,其孔径尺寸和孔形成的原因有关。由于材料中水的挥发,在凝胶丝上会存在大量的小孔,该孔仅与材料本身以及支架的含水量有关,与支架的填充方式几乎没有关系;另一种较大的孔是由打印中的填充间隙引起的,并且直接由支架算法确定。根据Solidworks中对不同填充间隙支架模型的物理评估,可以计算得到各支架的理论孔隙率,具体评估结果如表2所示。"

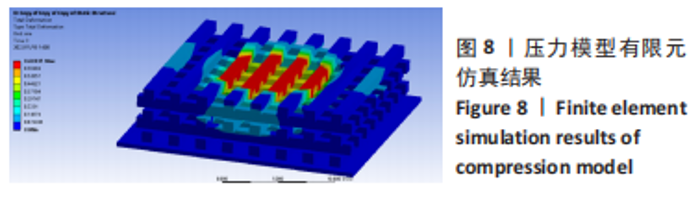

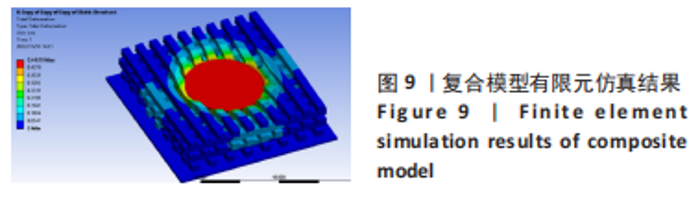

表2结果表明,在凝胶丝直径不变的前提下,填充间隙越大,支架的理论孔隙率越大,对于截面1 mm×1 mm的凝胶丝,支架的理论孔隙率从1.5 mm填充时的33%上升到2.5 mm填充时的60%。需要说明的是,在实际应用中由于支架含水量的不同,支架的实际孔隙率会相较理论孔隙率有所增大,增大幅度与支架的脱水程度有关。 2.5 压力模型有限元仿真 对三维模型进行压力仿真可以预测支架在外力作用下的变形情况,支架最大变形量和所受外力之间的关系可以用来评价支架的抗压性能。图8所示是填充间隙2.5 mm的三维支架模型在压力1 N时的变形情况,图中不同的颜色表示支架不同部位的变形量。从图中可以看出受力区域的变形最大为0.669 mm,相对于支架5 mm的高度,相对变形量为13.4%,结合压力1 N和受力面积78.5 mm2,可以计算模型的弹性模量约为95 000 Pa。同样的方法可以计算得到填充间隙为2 mm的支架模型在1 N下的最大变形量为0.403 mm,模型的弹性模量约为160 000 Pa,填充间隙1.5 mm的支架模型在1 N下的最大变形量为0.28 mm,模型的弹性模量约230 000 Pa,这与结果2.3中所做的力学性能测试基本一致。"

当对模型进行优化后得到复合模型,预计支架的弹性模量可以按照混合定律进行计算,即不同填充间隙模型的弹性模量乘以该模型所占的比例,最终相加得到复合模型的弹性模量。对模型进行优化后,模型共由5层凝胶丝构成,其中3层按2 mm的填充间隙进行填充,占总体积的60%;2层按2.5 mm的填充间隙进行填充,占总体积的40%,根据2 mm填充所得支架的弹性模量为160 000 Pa,2.5 mm填充所得支架的弹性模量为95 000 Pa,可以计算得到该复合模型的弹性模量,预计在1 N的外力作用下最大变形量为0.495 8 mm。图9中所示为该复合模型的有限元仿真结果,仿真结果显示该模型在1 N的外力作用下最大变形量为0.492 3 mm,与预测结果误差范围小于1%。通过对该模型进行物理性能的评估可以得到该模型的理论孔隙率为54%,同样与混合定律计算得到的理论孔隙率相一致。"

| [1] GAO D, WANG Z, WU Z, et al. 3D-printing of solvent exchange deposition modeling (SEDM) for a bilayered flexible skin substitute of poly (lactide-co-glycolide) with bioorthogonally engineered EGF. Mater Sci Eng C. 2020;112:110942. [2] 余海洋,游德淑,顾晓诚,等.基于生物3D打印技术的芍药苷-海藻酸钠-明胶皮肤支架体外生物相容性研究[J].介入放射学杂志, 2022,31(6):582-586. [3] TORRES M, SINHA R, MOTA C, et al.Improving cell distribution on 3D additive manufactured scaffolds through engineered seeding media density and viscosity. Acta Biomater. 2020;101:183-195. [4] EDMONDS M. Apligraf in the treatment of neuropathic diabetic foot ulcers. Int J Low Extrem Wounds. 2009;8(1):11-18. [5] TASHAKORI M,RAKHSHAN K,RAMEZ M, et al. Conductive carbon nanofibers incorporated into collagen bio-scaffold assists myocardial injury repair. Int J Biol Macromol.2020;163:1136-1146. [6] INTINI C, EIVIN, CABRAL J, et al. 3D-printed chitosan-based scaffolds: An in vitro study of human skin cell growth and an in-vivo wound healing evaluation in experimental diabetes in rats. Carbohyd Polym. 2018;199:593-602. [7] ORYAN A, SAHVIEH S. Effectiveness of chitosan scaffold in skin, bone and cartilage healing. Int J Biol Macromol. 2017;104:1003-1011. [8] KOCH L, KUHN S, SORG H, et al. Laser printing of skin cells and human stem cells. Tissue Eng Part C Methods. 2010;16(5):847-854. [9] YOON H, LEE J, YIM H, et al. Development of cell-laden 3D scaffolds for efficient engineered skin substitutes by collagen gelation. Rsc Adv. 2016;6(26):21439-21447. [10] 刘煜凡,黄沙,姚斌,等.3D生物打印的微结构促进小鼠表皮干细胞的增殖和活性[J].南方医科大学学报,2017,37(6):761-766. [11] 曹思玮,安佰超,乡世健,等.3D打印隐丹参酮水凝胶面膜的抗痤疮作用及皮肤安全性评价[J].中国皮肤性病学杂志,2019,33(3): 371-378. [12] BILLIET T, GEVAERT E, SCHRYVER T, et al. The 3D printing of gelatin methacrylamide cell-laden tissue-engineered constructs with high cell viability. Biomaterials. 2014;35(1):49-62. [13] CRABTREE RH. Hypervalency, secondary bonding and hydrogen bonding: siblings under the skin. Chem Soc Rev. 2017;46(6):1720-1729. [14] YANG W, XU H, LAN Y, et al. Preparation and characterisation of a novel silk fibroin/hyaluronic acid/sodium alginate scaffold for skin repair. Int J Biol Macromol. 2019;130:58-67. [15] PAL P, SRIVAS P, DADHICH P, et al. Nano-/microfibrous cotton-wool-like 3D scaffold with core–shell architecture by emulsion electrospinning for skin tissue regeneration. ACS Biomater Sci Eng. 2017;3(12):3563-3575. [16] WANG J, SUN X, CHENG N, et al. In vitro and in vivo studies of a collagen-based scaffold carrying PLGA microspheres for sustained release of epidermal growth factor in skin regeneration. J Biomater Tiss Eng. 2017;7(12):1336-1343. [17] MIAO Z,S EO J, HICKNER MA. Solvent-cast 3D printing of polysulfone and polyaniline composites. Polymer. 2018;152:18-24. [18] ATOUFI Z, ZARRINTAJ P, MOTLAGH GH, et al. A novel bio electro active alginate-aniline tetramer/agarose scaffold for tissue engineering: synthesis, characterization, drug release and cell culture study. J Biomater Sci Polym Ed. 2017;28(15):1617-1638. [19] HAN S, LEE JY, HEO EY, et al. Implantation of a Matrigel-loaded agarose scaffold promotes functional regeneration of axons after spinal cord injury in rat. Biochem Biophys Res Commun. 2018;496(3):785-791. [20] HUANG Y, WANG J, YANG F, et al. Modification and evaluation of micro-nano structured porous bacterial cellulose scaffold for bone tissue engineering. Mater Sci Eng C Mater Biol Appl. 2017;75:1034-1041. [21] DANIELE M, ADAMS A, NACIRI J, et al. Interpenetrating networks based on gelatin methacrylamide and PEG formed using concurrent thiol click chemistries for hydrogel tissue engineering scaffolds. Biomaterials. 2014;35(6):1845-1856. [22] 冯辰,周骥平,许晓东,等.3D打印生物材料微小力学性能自动测量系统的设计[J].中国组织工程研究,2022,26(21):3306-3311. [23] JIANG Y, ZHOU J, ZHANG Q, et al. Preparation of cellulose nanocrystals from Humulus japonicus stem and the influence of high temperature pretreatment. Carbohyd Polym. 2017;164:284-293. [24] 鲍晶晶,谢璠,党婉斌,等.TEMPO氧化纳米纤维素增强芳纶云母纸基复合材料及其性能研究[J].陕西科技大学学报,2019,37(5):1-7. [25] 薛刚,何易,李小白,等.超声辅助硫酸水解法制备银杏果壳纳米纤维素及其特性表征[J].食品工业科技,2021,42(14):204-211. [26] 姜亚妮.草源性纳米纤维素复合明胶的制备及生物3D打印皮肤支架成型工艺的研究[D].扬州:扬州大学,2018. [27] XU X, ZHOU J, JIANG Y, et al. 3D printing process of oxidized nanocellulose and gelatin scaffold. J Biomater Sci Polym Ed. 2018; 29(12):1498-1513. [28] 刘东方,周骥平,许晓东,等.基于FLUENT3D 生物打印喷头内部流场的数值模拟分析[J].中国组织工程研究,2018,22(2):274-280. |

| [1] | Yang Jie, Hu Haolei, Li Shuo, Yue Wei, Xu Tao, Li Yi. Application of bio-inks for 3D printing in tissue repair and regenerative medicine [J]. Chinese Journal of Tissue Engineering Research, 2024, 28(3): 445-451. |

| [2] | Kong Xiangyu, Wang Xing, Pei Zhiwei, Chang Jiale, Li Siqin, Hao Ting, He Wanxiong, Zhang Baoxin, Jia Yanfei. Biological scaffold materials and printing technology for repairing bone defects [J]. Chinese Journal of Tissue Engineering Research, 2024, 28(3): 479-485. |

| [3] | Liu Chunlei, , , Yao Xi, Wei Zhengbo, Xie Ying. Construction methods and application of assembloids [J]. Chinese Journal of Tissue Engineering Research, 2024, 28(1): 113-120. |

| [4] | Peng Zhixin, Yan Wengang, Wang Kun, Zhang Zhenjiang. Finite element analysis and structural optimization design of 3D printed forearm braces [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(9): 1340-1345. |

| [5] | He Yinhao, Li Xiaosheng, Chen Hongwen, Chen Tiezhu. 3D printed porous tantalum metal in the treatment of developmental dysplasia of the hip: current status and application prospect [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(9): 1455-1461. |

| [6] | Wang Yanjin, Zhou Yingjie, Chai Xubin, Zhuo Hanjie. Meta-analysis of the efficacy and safety of 3D printed porous titanium alloy fusion cage in anterior cervical discectomy and fusion [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(9): 1434-1440. |

| [7] | Chai Hao, Yang Deyong, Zhang Lei, Shu Li. 3D printing personalized osteotomy guide technology versus conventional total knee arthroplasty on the accuracy of lower limb force alignment: a meta-analysis [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(4): 646-654. |

| [8] | Wu Minhui, Tang Changye, Dai Yuexing, Zheng Liqin, Li Zhihong, Li Shaobin, Lin Ziling. Difference in mechanical properties of osteoporotic bone trabecular 3D models with different gray thresholds [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(36): 5766-5770. |

| [9] | Wang Chuan, Wang Jinhang, Liu Rundong, Zhang Jing, Li Lin, Liu Zhicheng. Numerical simulation of the relationship between apparent elastic modulus and tissue elastic modulus of the trabecular meshwork in rats [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(35): 5649-5652. |

| [10] | Wang Xinjie, Wang Guodong, Zheng Zhongren, Shao Yiming, Wang Jialiang, Ma Hui, Zhao Xiaowei. Manganese-containing bioceramic materials in the field of bone repair [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(34): 5570-5576. |

| [11] | Huang Yuying, Guo Yi, Han Xinzuo, Min Hongwei, Li Xuemei, Liu Kemin. Functional correlation between the elasticity of the quadriceps and its tendons and osteoarthritis of the knee based on shear wave elastography measurements [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(31): 4971-4976. |

| [12] | Wu Jiang, Yin Han, Yan Zineng, Tian Guangzhao, Ding Zhengang, Yuan Xun, Fu Liwei, Tian Zhuang, Sui Xiang, Liu Shuyun, Guo Quanyi. Preparation of hierarchical porous cartilage composite scaffolds loaded with stromal cell-derived factor-1 using low-temperature deposition 3D printing [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(30): 4776-4782. |

| [13] | Jiu Jingwei, Liu Haifeng, Wang Guishan, Li Dijun, Yan Lei, Zhao Bin, Wang Bin. Functional characteristics of three-dimensional biological scaffolds for repairing injured spinal cord [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(30): 4876-4882. |

| [14] | Jiang Haifang, Liu Rong, Hu Peng, Chen Wei, Wei Zairong, Yang Chenglan, Nie Kaiyu. Application of 3D printing technology in the precise and personalized treatment of cleft lip and palate [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(3): 413-419. |

| [15] | Zhai Hongjie, Han Guanda, Li Lei, Dong Xiaohui, Jiang Zhiquan, Lou Feiyun. 3D printed polyetheretherketone material for skull defect repair [J]. Chinese Journal of Tissue Engineering Research, 2023, 27(3): 380-384. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||