[1] MA B, WU X, LI Y, et al. Digital Surgical Guides in Mandibular Genioplasty: Evaluating Precision Against Conventional Techniques. Aesthetic Plast Surg. 2024;48(19):3741-3750.

[2] 宋鑫利,张玮,于笑,等.数字化技术在正颌外科治疗中的应用进展[J].山东医药,2024,64(4):99-102.

[3] 许梅,冯莹,孙旭,等.3D打印个性化钛板在颧骨骨折复位固定中的临床效果[J].临床误诊误治,2022,35(1):67-69.

[4] 寿雨薇,金诗韵,蔡鸣.3D打印个性化钛合金内植物在口腔颌面外科的应用进展[J].口腔材料器械杂志,2017,26(2):102-106.

[5] XIE L, CHEN C, ZHANG Y, et al. Three-dimensional printing assisted ORIF versus conventional ORIF for tibial plateau fractures: A systematic review and meta-analysis. Int J Surg. 2018;57:35-44.

[6] 李莉,孙健,李亚莉,等.数字化技术用于25例患者正颌手术效果评价[J].上海口腔医学,2021,30(2):219-224.

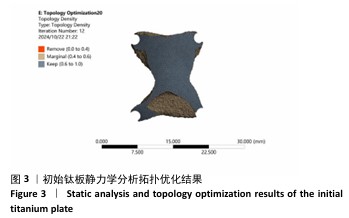

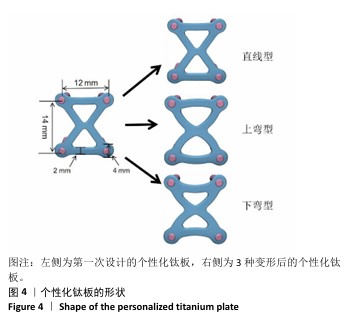

[7] 唐志雄,李亚兰,郭维鹏,等.下颌角缺损修复钛板构型的拓扑优化[J].医用生物力学,2014,29(2):167-173.

[8] LIU YF, FAN YY, JIANG XF, et al. A customized fixation plate with novel structure designed by topological optimization for mandibular angle fracture based on finite element analysis. Biomed Eng Online. 2017;16(1):131.

[9] HU W, AGRAWAL M, THADANI S, et al. Comparative evaluation of a single 2.0-mm AO locking reconstruction plate with conventional miniplate osteosynthesis for treatment of linear non-comminuted fractures of symphysis and parasymphsis region of the mandible. J Stomatol Oral Maxillofac Surg. 2019;120(1):11-15.

[10] GOODDAY RH. Management of fractures of the mandibular body and symphysis. Oral Maxillofac Surg Clin North Am. 2013;25(4):601-616.

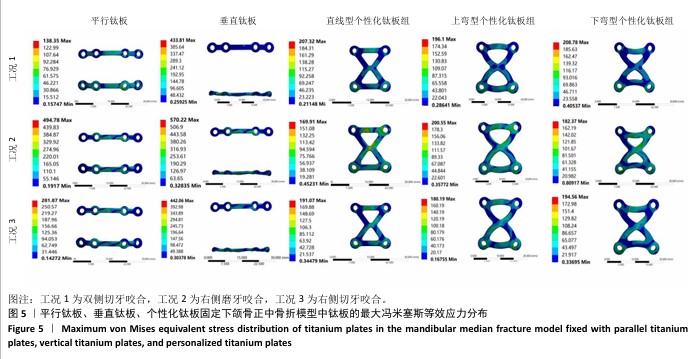

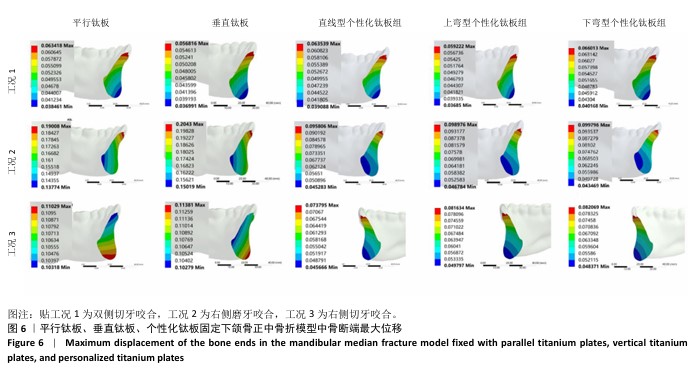

[11] JI B, WANG C, LIU L, et al. A biomechanical analysis of titanium miniplates used for treatment of mandibular symphyseal fractures with the finite element method. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2010;109(3):e21-e27.

[12] WESTBURY LD, SHERE C, EDWARDS MH, et al. Cluster Analysis of Finite Element Analysis and Bone Microarchitectural Parameters Identifies Phenotypes with High Fracture Risk. Calcif Tissue Int. 2019;105(3): 252-262.

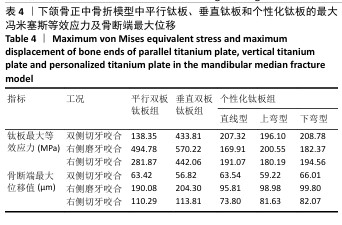

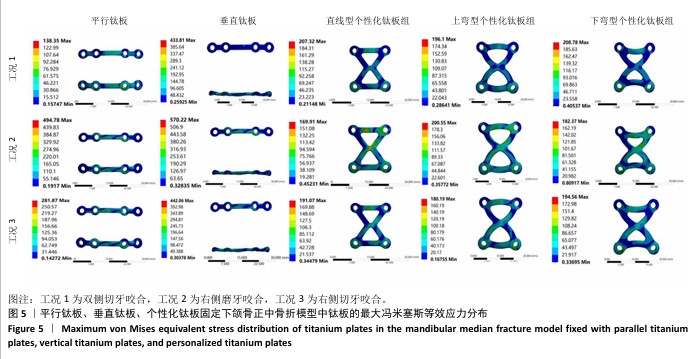

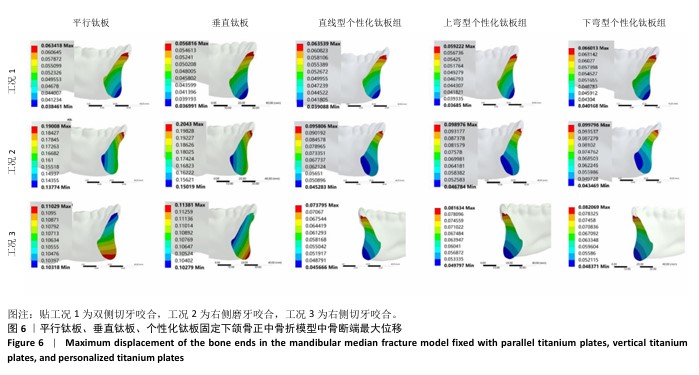

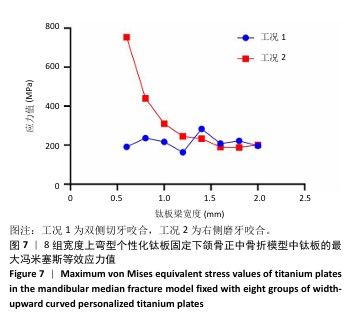

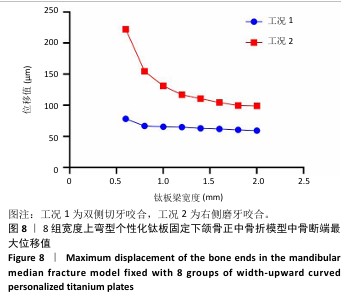

[13] 王怀升,刘锐,宋振宇,等.3D打印钛合金下颌骨正中联合骨折接骨板的应力分布及静态力学分析[J].口腔医学研究,2024,40(6): 519-524.

[14] 顾卫平,殷新民,张红,等.利用可视化人体图像确定咀嚼肌三维肌力向量的研究[J].口腔医学,2007,27(9):455-456.

[15] KORIOTH TW, HANNAM AG. Deformation of the human mandible during simulated tooth clenching. J Dent Res. 1994;73(1):56-66.

[16] KOZAKIEWICZ M, SWINIARSKI J. “A” shape plate for open rigid internal fixation of mandible condyle neck fracture. J Craniomaxillofac Surg. 2014;42(6):730-737.

[17] PERREN SM. Physical and biological aspects of fracture healing with special reference to internal fixation. Clin Orthop Relat Res. 1979;(138):175-196.

[18] BHAGAT JA, NAGANATHAN V, KRISHNAN L, et al. Development of a new V-shaped implant with locking plates and screws for mandibular fracture fixation: an in vitro study using finite element analysis. Br J Oral Maxillofac Surg. 2019;57(8):805-807.

[19] ZHOU W, RONG Q, AN J, et al. Finite Element Analysis of Two- and Three-Dimensional Fixation in Treating Mandibular Symphyseal Fracture Combined With Bilateral Condylar Intracapsular Fractures. J Craniofac Surg. 2021;32(7):2557-2561.

[20] DAQIQ O, ROOSSIEN CC, WUBS FW, et al. Biomechanical assessment of mandibular fracture fixation using finite element analysis validated by polymeric mandible mechanical testing. Sci Rep. 2024;14(1):11795.

[21] ALBOGHA MH, MORI Y, TAKAHASHI I. Three-dimensional titanium miniplates for fixation of subcondylar mandibular fractures: Comparison of five designs using patient-specific finite element analysis. J Craniomaxillofac Surg. 2018;46(3):391-397.

[22] 张瑞娟,高全文.3D钛板固定下颌骨骨折的生物力学研究及应用进展[J].中国美容整形外科杂志,2018,29(4):240-242.

[23] JOSHI U, KURAKAR M. Comparison of Stability of Fracture Segments in Mandible Fracture Treated with Different Designs of Mini-Plates Using FEM Analysis. J Maxillofac Oral Surg. 2014;13(3):310-319.

[24] LOVALD S, BAACK B, GABALL C, et al. Biomechanical optimization of bone plates used in rigid fixation of mandibular symphysis fractures. J Oral Maxillofac Surg. 2010;68(8):1833-1841.

[25] LOVALD ST, WAGNER JD, BAACK B. Biomechanical optimization of bone plates used in rigid fixation of mandibular fractures. J Oral Maxillofac Surg. 2009;67(5):973-985.

[26] LI Y, LI H, LAI Q, et al. Finite element analysis of 3D-printed personalized titanium plates for mandibular angle fracture. Comput Methods Biomech Biomed Engin. 2023;26(1):78-89.

[27] PRASAD K, BAZAKA O, CHUA M, et al. Metallic Biomaterials: Current Challenges and Opportunities. Materials (Basel). 2017;10(8):884.

[28] ORASSI V, FISCHER H, DUDA GN, et al. In Silico Biomechanical Evaluation of WE43 Magnesium Plates for Mandibular Fracture Fixation. Front Bioeng Biotechnol. 2021;9:803103.

[29] PRASADH S, KRISHNAN AV, LIM CYH, et al. Titanium versus magnesium plates for unilateral mandibular angle fracture fixation: biomechanical evaluation using 3-dimensional finite element analysis. J Mater Res Technol. 2022;18:2064-2076.

[30] XING F, LI S, YIN D, et al. Recent progress in Mg-based alloys as a novel bioabsorbable biomaterials for orthopedic applications. JMA. 2022;10(6):1428-1456.

[31] AYASAKA K, RAMANATHAN M, HUY NX, et al. Evaluation of Hard and Soft Tissue Responses to Four Different Generation Bioresorbable Materials-Poly-l-Lactic Acid (PLLA), Poly-l-Lactic Acid/Polyglycolic Acid (PLLA/PGA), Uncalcined/Unsintered Hydroxyapatite/Poly-l-Lactic Acid (u-HA/PLLA) and Uncalcined/Unsintered Hydroxyapatite/Poly-l-Lactic Acid/Polyglycolic Acid (u-HA/PLLA/PGA) in Maxillofacial Surgery: An In-Vivo Animal Study. Materials (Basel). 2023;16(23):7379.

[32] ARORA L, BHARDWAJ S, HASHMI GS, et al. Finite Element Analysis (FEA) of Perpendicular Plating Versus Conventional Plating in Mandibular Symphysis Fracture. J Maxillofac Oral Surg. 2020;19(1):143-148.

[33] SONG IS, CHOI J, KIM SR, et al. Stability of bioabsorbable fixation systems according to different locations of mandibular fracture: A three-dimensional analysis. J Craniomaxillofac Surg. 2021;49(8): 732-737.

[34] 周宗昊,罗思阳,陈佳文,等.生物可吸收板与微型钛板在不同骨质下颌骨骨折固定中的有限元分析[J].中国组织工程研究,2025, 29(4):818-826. |