中国组织工程研究 ›› 2017, Vol. 21 ›› Issue (6): 821-828.doi: 10.3969/j.issn.2095-4344.2017.06.001

• 组织工程骨及软骨材料 tissue-engineered bone and cartilage materials • 下一篇

一种可注射生物活性磷酸钙骨修复材料的制备及表征

刘健休1,沈 莹2,储 彬2,曾 飞1,黄世嘉1,李松建1

- 1南方医科大学珠江医院,广东省广州市 510280;2深圳清华大学研究院,广东省深圳市 518057

Preparation and characterization of an injectable bioactive calcium phosphate material for bone repair

Liu Jian-xiu1, Shen Ying2, Chu Bin2, Zeng Fei1, Huang Shi-jia1, Li Song-jian1

- 1Zhujiang Hospital of Southern Medical University, Guangzhou 510280, Guangdong Province, China; 2Research Institute of Tsinghua University in Shenzhen, Shenzhen 518057, Guangdong Province, China

摘要:

文章快速阅读:

.jpg)

文题释义:

磷酸四钙:是磷酸钙系列骨水泥最重要的组成原料之一,作为惟一钙磷比高于羟基磷灰石且碱性仅次于氧化钙、氢氧化钙的磷酸盐,其能够与其他低钙磷比的磷酸盐形成理想的磷酸钙骨水泥,但目前国内尚未有其产品销售,资料显示,碳酸钙和磷酸氢钙或二水磷酸氢钙是最常见的合成磷酸四钙的方法。

固化液:骨水泥一般包括固相的粉体和液相的固化液,常见的固化液有氯化钠溶液、磷酸氢铵水溶液、磷酸氢钠溶液、柠檬酸溶液及一些高分子水溶液。根据不同的要求,选择合适固化液对骨水泥的综合性能影响非常明显,实验需选择磷酸氢铵水溶液、磷酸氢钠溶液及柠檬酸溶液或其混合溶液作为固化液,探索其对骨水泥凝固时间、溶血率、环境pH、放热性、崩解性、细胞生物相容性等的影响。

背景:针对当前自体骨和异体骨移植治疗骨缺损存在的种种问题,急需研制生物活性可降解人工骨修复材料,特别是磷酸钙骨修复材料,目前依然是国内外研究的热点之一。

目的:旨在开发一种磷酸四钙基可注射生物活性磷酸钙骨修复材料。

方法:通过磷酸四钙基磷酸钙骨水泥原粉和无水磷酸氢钙以及不同组分固化液在室温下(25 ℃左右)混合制成可注射活性骨水泥,并通过X射线衍射,水泥硬度测定,在模拟体液中崩解以及溶血实验和细胞毒性实验等方法进行研究,探索其固体成分构成、液相构成、煅烧及干燥温度等条件对其物理性能、生物学性能的影响,从而筛选出一种或多种综合性能优异的骨修复材料。

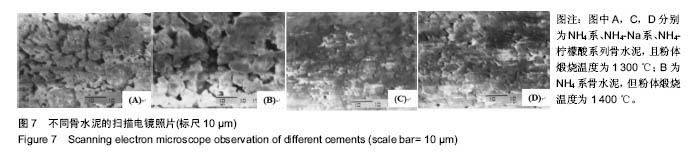

结果与结论:①煅烧温度低于1 300 ℃时,磷酸四钙产量很少,只有当温度接近1 400 ℃时,可以得到比较纯净的磷酸四钙;②极冷条件因避免了空气中水分的影响,得到大量纯净的磷酸四钙,而慢冷后的产物主要为羟基磷灰石,这说明极冷对于获得纯净的磷酸四钙至关重要;③随着液相中柠檬酸溶液比例的提高,骨水泥浸泡液中的pH值和溶血率逐渐增大,这说明柠檬酸溶液很容易导致溶血;④通过体外细胞实验证实,在液相选择上,NH4/Na比为2∶1的磷酸氢铵和磷酸氢钠溶液构成的骨水泥溶血率最低,细胞生物相容性最好,最有利于细胞生长;⑤1 400 ℃煅烧后过筛得到的粉体组成的骨水泥初凝时间最短,pH值影响最小,崩解性不高,溶血率最低,对细胞的抑制作用更小,这说明经过1 400 ℃煅烧,过筛粉体得到的骨水泥更加适合临床应用。

ORCID: 0000-0001-8897-6080(刘健休)

中图分类号:

.jpg)

.jpg)

.jpg)

.jpg)