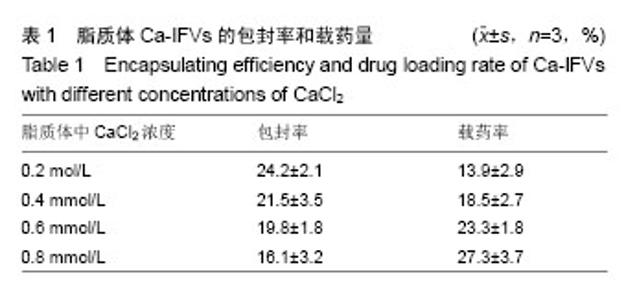

| [1] Habibovic P,de Groot K.Osteoinductive biomaterials - properties and relevance in bone repair.J Tissue Eng Regen Med. 2007; 1(1):25-32.[2] Rosa AL,de Oliveira PT,Beloti MM.Macroporous scaffolds associated with cells to construct a hybrid biomaterial for bone tissue engineering.Expert Rev Med Devic.2008;5(6):719-728.[3] Bauer TW,Muschler GF.Bone graft materials-An overview of the basic science.Clin Orthop Relat R. 2000;(371):10-27.[4] O'Keefe RJ,Mao J.Bone tissue engineering and regeneration: from discovery to the clinic--an overview. Tissue Eng Part B Rev. 2011;17(6):389-392.[5] Betz RR.Limitations of autograft and allograft: new synthetic solutions.Orthopedics.2002;25(5 Suppl):s561-570.[6] 刘晶,胡杨,沈玉凤,等.壳聚糖与海藻酸钙双相陶瓷骨支架的机械性能及细胞相容性[J].中国组织工程研究, 2016,20(8):1104-1110.[7] 安帅星,于美丽,郭宏玥,等.三种温控脱细胞载体的制备与性能评估[J].中国组织工程研究,2015,19(43): 7004-7009.[8] Ni P,Ding Q,Fan M,et al.Injectable thermosensitive PEG-PCL-PEG hydrogel/acellular bone matrix composite for bone regeneration in cranial defects.Biomaterials. 2014;35(1): 236-248.[9] Na K,Kim SW,Sun BK,et al.Osteogenic differentiation of rabbit mesenchymal stem cells in thermo-reversible hydrogel constructs containing hydroxyapatite and bone morphogenic protein-2 (BMP-2). Biomaterials. 2007;28(16):2631-2637.[10] Baia X,Lüa SY,Caob Z,et al.Self-reinforcing injectable hydrogel with both high water content and mechanical strength for bone repair.Chem Eng J.2016;288:546-556.[11] Tan H,Marra KG.Injectable biodegradable hydrogels for tissue engineering applications. Materials.2010;3(3):1746-1767.[12] Ahl PL,Chen L,Perkins WR,et al.Interdigitation-fusion a new method for producing lipid vesicles of high internal volume. Biochimica Biophysica Acta.1994;1195(2):237-244.[13] Messersmith PB,Vallabhaneni S,Nguyen V.Preparation of calcium-loaded liposomes and their use in calcium phosphate formation.Chem Mater.1998;10(1):109-116.[14] Paleos CM,Tsiourvas D,Sideratou Z.Preparation of multicompartment lipid-based systems based on vesicle interactions.Langmuir. 2012;28(5):2337-2346.[15] Sokolove PM,Kester MB.Quantitation of Ca2+ uptake by arsenazo-3-loaded liposomes.Anal Biochem. 1989;177(2): 402-406.[16] Smith AM,Harris JJ,Shelton RM,et al.3D culture of bone-derived cells immobilised in alginate following light-triggered gelation.J Control Release.2007;119(1):94-101.[17] Li J,Wang XL,Zhang T,et al.A review on phospholipids and their main applications in drug delivery systems.Asian J Pharm Sci. 2015;10(2):81-98.[18] May JP,Ernsting MJ,Undzys E,et al.Thermosensitive liposomes for the delivery of gemcitabine and oxaliplatin to tumors.Mol Pharm. 2013;10(12):4499-4508.[19] Westhaus E,Messersmith PB.Triggered release of calcium from lipid vesicles: a bioinspired strategy for rapid gelation of polysaccharide and protein hydrogels.Biomaterials. 2001;22(5): 453-462.[20] Lee GS,Park JH,Shin US,et al.Direct deposited porous scaffolds of calcium phosphate cement with alginate for drug delivery and bone tissue engineering.Acta Biomater.2011;7(8):3178-3186.[21] Gleeson JP, Plunkett NA, O'Brien FJ.Addition of hydroxyapatite improves stiffness, interconnectivity and osteogenic potential of a highly porous collagen-based scaffold for bone tissue regeneration. Eur Cell Mater.2010;20(4):218-230.[22] Branco da Cunha C,Klumpers DD,Mooney DJ,et al.Influence of the stiffness of three-dimensional alginate/collagen-I interpenetrating networks on fibroblast biology.Biomaterials. 2014;35(32):8927-8936.[23] Celik E,Bayram C,Akcapinar R,et al.The effect of calcium chloride concentration on alginate/Fmoc-diphenylalanine hydrogel networks.Mater Sci Eng C Mater Biol Appl.2016;66:221-229.[24] Engler AJ,Sen S,Sweeney HL,et al.Matrix elasticity directs stem cell lineage specification.Cell 2006;126(4):677-689.[25] Guilak F,Cohen DM,Chen CS,et al.Control of stem cell fate by physical interactions with the extracellular matrix.Cell Stem Cell. 2009;5(1):17-26.[26] Park JS,Chu JS,Li S,et al.The effect of matrix stiffness on the differentiation of mesenchymal stem cells in response to TGF-beta.Biomaterials.2011;32(16):3921-3930.[27] Swift J,Ivanovska IL,Discher DE,et al.Nuclear lamin-A scales with tissue stiffness and enhances matrix-directed differentiation. Science.2013;341(6149):1240104.[28] Khetan S,Guvendiren M,Burdick JA,et al.Degradation-mediated cellular traction directs stem cell fate in covalently crosslinked three-dimensional hydrogels.Nat Mater.2013;12(5):458-465. |