| [1] Sterodimas A, de Faria J. Human auricular tissue engineering in an immunocompetent animal model. Aesthet Surg J. 2013;33(2):283-289.

[2] Cheng NC, Estes BT, Young TH, et al. Engineered cartilage using primary chondrocytes cultured in a porous cartilage derived matrix. Regen Med. 2011;6(1):81-93.

[3] Fishman JM, De Coppi P, Elliott MJ, et al. Airway tissue engineering. Expert Opin Biol Ther. 2011;11(12):1623 1635.

[4] Fisher MB, Mauck RL. Tissue engineering and regenerative medicine: recent innovations and the transition to translation. Tissue Eng Part B Rev. 2013;19(1):1-13.

[5] Lu T, Li Y and Chen T. Techniques for fabrication and construction of three dimensional scaffolds for tissue engi¬neering. Int J Nanomedicine. 2013;8(3):337-350.

[6] Deng Y, Lin XS, Zheng Z, et al. Poly (hydroxybutyrate-co- hydroxyhexanoate) promoted production of extracellular matrix of articular cartilage chondrocytes in vitro. Biomaterials. 2003;24(23):4273-4281.

[7] Veleirinho B, Coelho DS, Dias PF, et al. Nanofibrous poly (3- hydroxybutyrate-co-3 hydroxyvalerate)/chitosan scaffolds for skin regeneration. Int J Biol Macromol. 2012;51(4):343-350.

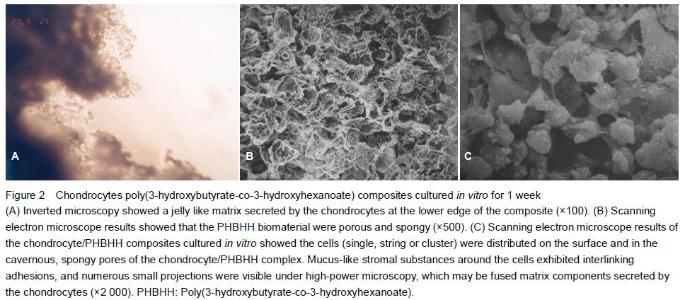

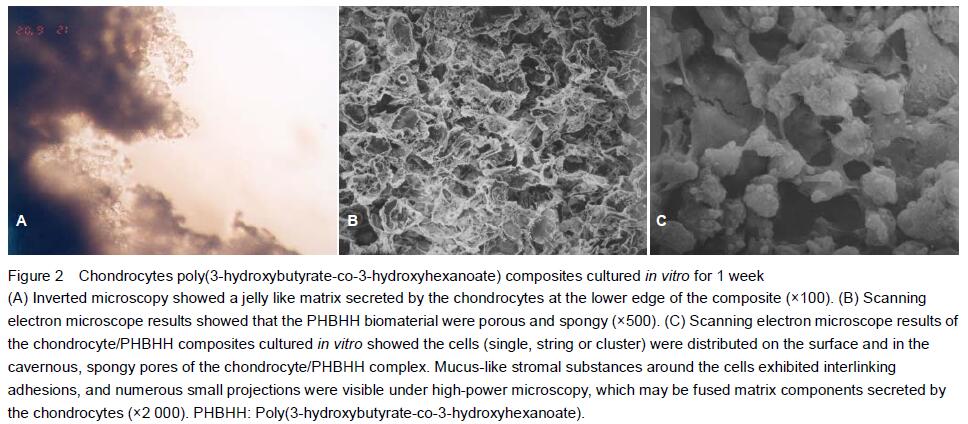

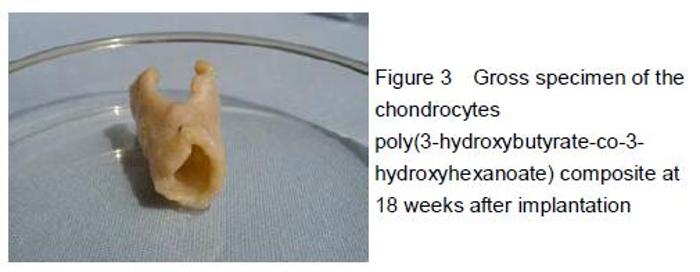

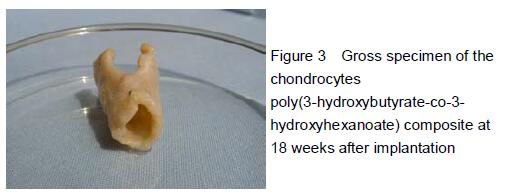

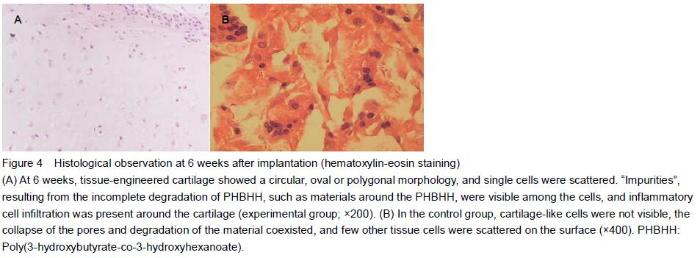

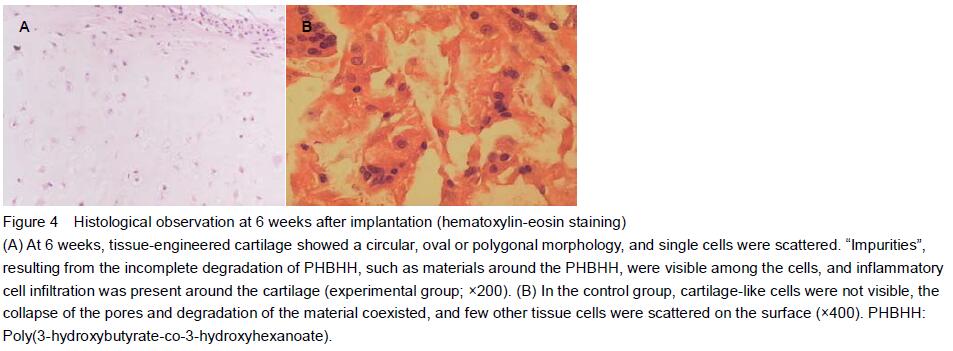

[8] Sun AK, Sun J, Sun W, et al. Applicability and biodegradability in vivo upon polyglycolic acid nonwoven mesh and poly (3-hydroxybutyrate-co-3-hydroxyhexanoate) porous sponge as scaffolds for tissue engineered cartilage. Zhongguo Zuzhi Gongcheng Yanjiu. 2014;18(8):1172-1178.

[9] Zhang WJ, Cao YL. Progress and challenges in tissue engineering: the development of national tissue engineering center in China. Scientia Sinica (Vitae). 2014;44(2):132-138.

[10] Mikos AG, Sarakinos G, Leite SM, et al. Laminated three dimensional biodegradable foams for use in tissue engineering. Biomaterials. 1993;14(5):323-330.

[11] Zhang R, Ma PX. Poly (alpha-hydroxylacids)/hydroxyaptite porous composites for bone tissue engineering. I. Preparation and morphology. J Biomed Mater Res. 1999;44(4):446-455.

[12] Sun AK, Hu P, Li WT, et al. Fabrication of larynx-shape porous PHBHH for cartilage tissue engineering and the cytocompatibility with chondrocytes. Tinglixue Ji Yanyujibing Zazhi. 2011;19(6):558-561.

[13] Gilpin DA, Weidenbecher MS, Dennis JE. Scaffold free tissue engineered cartilage implants for laryngotracheal reconstruction. Laryngoscope. 2010;120(3):612-617.

[14] Shahin K, Doran PM. Improved seeding of chondrocytes into polyglycolic acid scaffolds using semi static and alginate loading methods. Biotechnol Prog. 2011;27(1):191-200.

[15] El Sayed K, Marzahn U, John T, et al. PGA associated heterotopic chondrocyte cocultures: implications of nasoseptal and auricular chondrocytes in articular cartilage repair. J Tissue Eng Regen Med. 2013;7(1):61-72.

[16] Chaim IA, Sabino MA, Mendt M, et al. Evaluation of the potential of novel PCL-PPDX biodegradable scaffolds as support materials for cartilage tissue engineering. J Tissue Eng Regen Med. 2012;6(4):272-279.

[17] Xue J, Feng B, Zheng R, et al. Engineering ear shaped cartilage using electrospun fibrous membranes of gelatin/ polycaprolactone. Biomaterials. 2013;34(11):2624- 2631.

[18] Liu SY, Chen JY, Chen QQ, et al. Construction of tissue-engineered cartilage with cross-linked sodium hyaluronate as scafold materials in vitro. Zhongguo Zuzhi Gongcheng Yanjiu. 2014;18(8):1191-1197.

[19] Chen ZF, Wu YL, Ma RN, et al. The construction of tissue engineering cartilage with a new poly-β-hydroxybutyrate scaffold. Xiandai Shengwu Yixue Jinzhan. 2013;13(4): 627-630.

[20] Zhao K, Deng Y, Chun CJ, et al. Polyhydroxyalkanoate (PHA) scaffolds with good mechanical properties and biocom patibility. Biomaterials. 2003;24(6):1041-1045. |