[1] 李正茂.生物活性玻璃组织工程支架的制备及细胞相容性研究[D].广州:华南理工大学,2013.

[2] JIANG LY, LI YB, XIONG CD. A novel composite membrane of chitosan-carboxymethyl cellulose polyelectr-olyte complex membrane filled with nano-hydroxyapatite Preparation and properties. J Mater Sci Mater Med. 2009;20(8):1645-1652.

[3] XU JL, KHOR KA, DONG ZL. Preparation and characterization of nano-sized hydroxyapatite powders produced in a radio frequency thermal plasma. Master Sci Eng. 2004;37(1):101-108.

[4] 王丽艳,王晶晶,黄楚宁,等.纳米生物活性玻璃对牙周支持组织缺损修复的研究[J].深圳中西医结合杂志,2020,30(15):1-2+199.

[5] 常宇辰,林子扬,谢昕,等.基于介孔硼硅酸盐生物活性玻璃微球的可注射复合骨水泥[J].无机材料学报,2020,35(12):1398-1406.

[6] 刘瑜.硼掺杂生物玻璃的降解和矿化性能研究[D].大连:大连理工大学,2019.

[7] 王薇,苏欣,王珍,等.含ZnO多孔生物玻璃骨修复支架的制备及体外性能研究[J].口腔颌面修复学杂志,2020,21(6):326-332+348.

[8] 王宏远,王薇,杨树青,等.多孔氮氧生物玻璃骨修复支架的制备及性能[J].中国组织工程研究,2021,25(16):2521-2527.

[9] 杨高峰,马艳丽.有机泡沫浸渍法Y-Al-Si多孔玻璃制备及性能研究[J].陶瓷,2017(11):28-32.

[10] 精密陶瓷室温弯曲强度(破坏模数)试验法[S].JIS R1601,2008.

[11] 欧阳鹿.掺锶溶胶-凝胶生物活性玻璃的制备及其多孔骨修复体研究[D].广州:华南理工大学,2020.

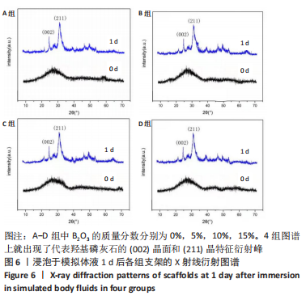

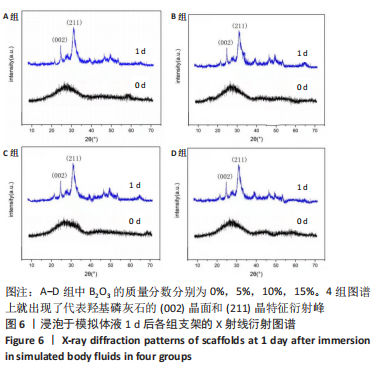

[12] 朱子旻,张敏慧,张轩宇,等.硼硅酸盐生物活性玻璃在直流电场下的体外矿化性能[J].无机材料学报,2021,36(9):1006-1012.

[13] AMIRHOSSEIN M, MOHAMMADAMIN Z, HAJI MTM, et al. Preparation,characterizationand in vitro biological response of simultaneous co-substitution of Zr4+/Sr2+ 58S bioactive glass powder. Ceram Int. 2021; 47(17) :23762-23769.

[14] MUBINA MSK, SHAILAJHA S, SANKARANARAYANAN R, et al. Enriched biological and mechanical properties of boron doped SiO2-CaO-Na2O-P2O5 bioactive glass ceramics (BGC). J Non-Cryst Solids. 2021;570. doi. 10.1016/j.jnoncrysol.2021.121007

[15] SCHUHLADEN K, USANEE PANTULAP U, ENGEL K, et al.Influence of the replacement of silica by boron trioxide on the properties of bioactive glass scaffolds. Appl Glass Sci. 2021;12(3):293-312.

[16] SMEDSKJAER MM, JENSEN M, YUE YZ. Effect of thermal history and chemical composition on hardness of silicate glasses. J Non-Cryst Solids. 2010;356(18):893-897.

[17] HAKKI SS, BOZKURT BS, HAKKI EE. Boron regulates mineralized tissue-associated proteins in osteoblasts (MC3T3-E1). J Trace Elem Med Biol. 2010;24(4):243-250.

[18] 陈力涛.硼硅酸盐生物玻璃支架的3D打印及其性能研究[D].南昌:南昌大学,2020.

[19] BAI N, CHEN WR, LUO LJ, et al. Effect of B2O3 on the structural and in vitrobiological assessment of mesoporous bioactive glass nanospheres. J Am Ceram Soc. 2021;(104):3058-3072.

[20] CHEN S, MICHÁLEK M, GALUSKOVÁ D, et al. Multi-targeted B and Co co-doped 45S5 bioactive glasses with angiogenic potential for bone regeneration. Mater Sci Eng C Mater Biol Appl. 2020;112:110909. |