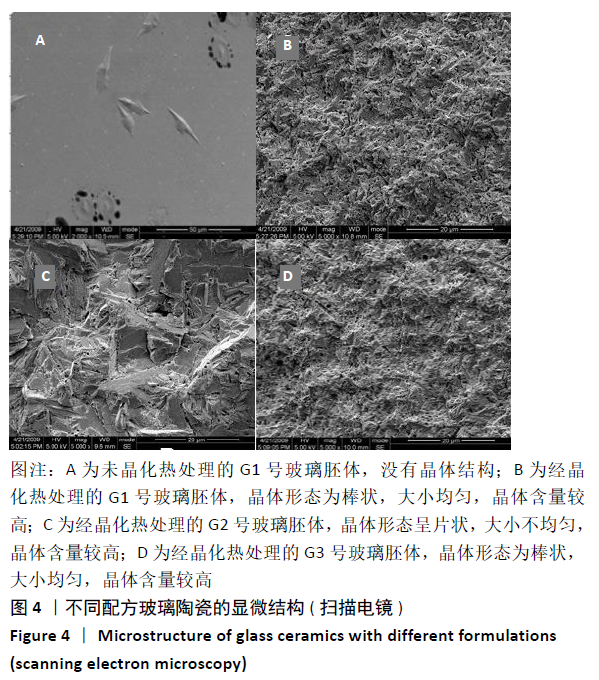

Chinese Journal of Tissue Engineering Research ›› 2021, Vol. 25 ›› Issue (34): 5427-5431.doi: 10.12307/2021.234

Previous Articles Next Articles

Microstructure and mechanical properties of the new dental glass ceramics with different formulations

Ren Shipeng1, Chen Xinmin2, Qing Song1, Yu Jie1, Yang Ting1, Tang Wanrong1

- 1Department of Stomatology, Affiliated Hospital of North Sichuan Medical College, Nanchong 637000, Sichuan Province, China; 2Department of Prosthodontics, West China Hospital of Stomatology, Sichuan University, Chengdu 610000, Sichuan Province, China