中国组织工程研究 ›› 2020, Vol. 24 ›› Issue (22): 3498-3503.doi: 10.3969/j.issn.2095-4344.2274

• 组织工程骨及软骨材料 tissue-engineered bone and cartilage materials • 上一篇 下一篇

3D打印钛合金骨小梁多孔结构的拉伸性能

张 兰1,王 翔2,刘 军2,张春秋1,叶金铎1,刘 璐2

- 1天津市先进机电系统设计与智能控制重点实验室,机电工程国家级实验教学示范中心,天津理工大学机械工程学院,天津市 300384;2天津市骨植入物界面功能化与个性研究企业重点实验室,嘉思特华剑医疗器材(天津)有限公司,天津市 300190

Tensile properties of three-dimensional printed porous titanium alloy trabecular bone

Zhang Lan1, Wang Xiang2, Liu Jun2, Zhang Chunqiu1, Ye Jinduo1, Liu Lu2

- 1Tianjin Key Laboratory for Advanced Mechatronic System Design and Intelligent Control, National Demonstration Center for Experimental Mechanical and Electrical Engineering Education, School of Mechanical Engineering of Tianjin University of Technology, Tianjin 300384, China; 2Key Laboratory of Bone Implant Interface Functionalization and Personalization Research Enterprise, Just Huajian Medical Device (Tianjin) Co., Ltd. Tianjin 300190, China

摘要:

文题释义:

3D打印:3D打印技术开创了增材制造的生产方式,即依照3D设计蓝图可将金属粉末等原材料逐层堆积而制成最终产品,擅长构建形状结构复杂的产品与个体化定制,制作特异性假体或植入物,供植入以达到重建等目的,在骨科领域得到了广泛应用。

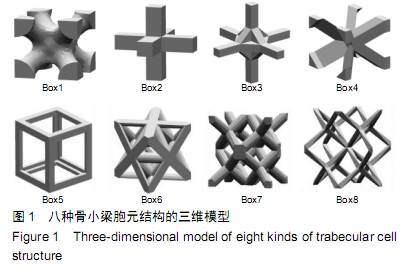

钛合金骨小梁:是以钛合金粉末为原材料,采用金属3D打印技术通过金属微粒逐层熔融叠加生成的一种类人体骨小梁三维空间网孔结构,其力学性能和生物学性能和人体的松质骨骨小梁极为相似,作为人工植入假体的表面结构,具有非常出色的骨长入效果。

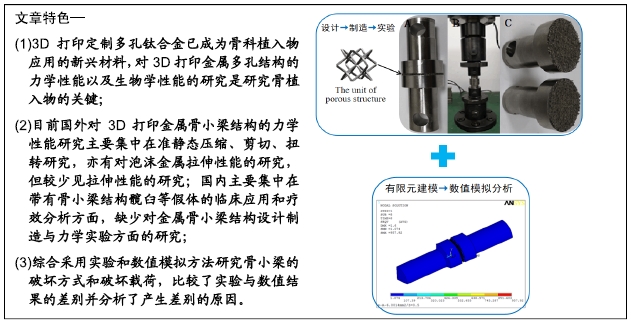

背景:3D打印钛合金多孔结构以其良好的机械性能和生物相容性已经在骨科植入假体设计与临床应用方面得到了快速发展,与涂层假体相比,钛合金骨小梁结构具有骨长入快和骨长入好的优点。为了保证骨科植入物的安全,目前多采用实验方式确定骨小梁结构的拉伸、剪切疲劳和弯曲疲劳强度。

目的:通过力学实验和有限元数值模拟方法研究骨小梁多孔结构的力学性能。

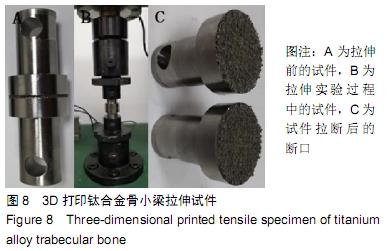

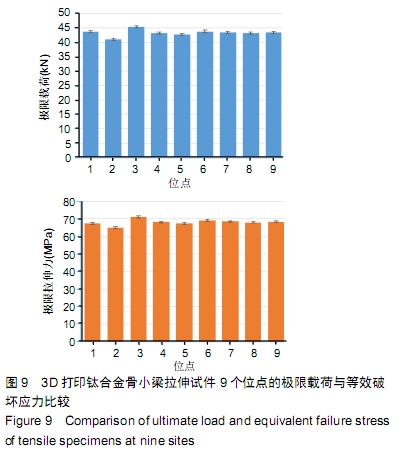

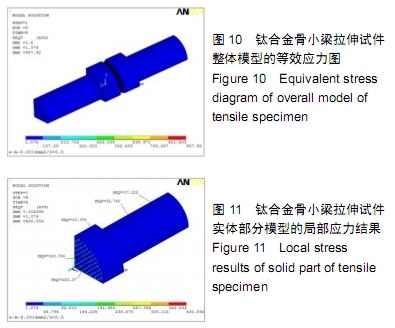

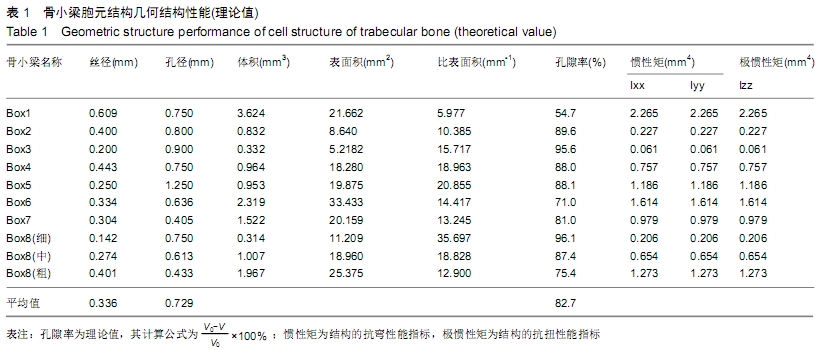

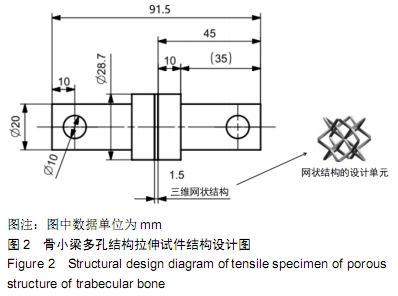

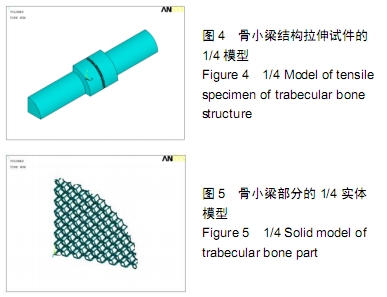

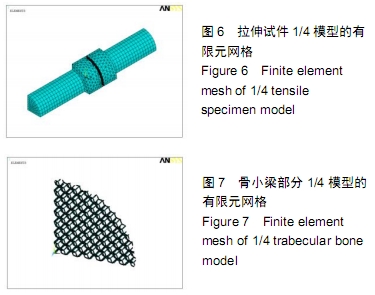

方法:①3D打印钛合金骨小梁拉伸试件实验:设计并制备3D打印钛合金骨小梁拉伸试件,骨小梁结构的丝径为0.28-0.35 mm、孔径为0.71 mm、孔隙率为73%。检测钛合金骨小梁结构的拉伸强度,分析其失效机制,同时分析不同打印位置对骨小梁拉伸强度的影响。②数值模拟实验:利用有限元方法建立包括骨小梁理论结构的拉伸试件实体模型,模拟骨小梁试件的拉伸破坏过程。

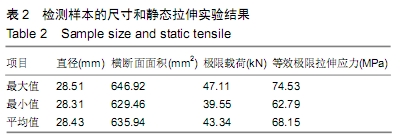

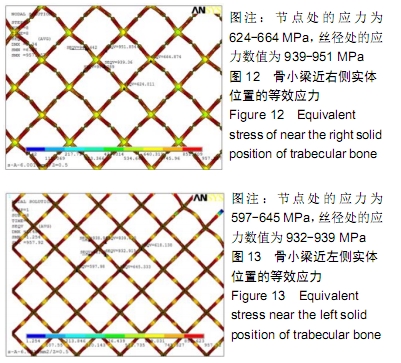

结果与结论:①3D打印钛合金骨小梁拉伸试件的极限载荷分布在39.55-47.11 kN之间,等效极限拉伸应力分布在62.79-74.53 MPa之间,拉伸破坏的结果为网状结构断裂,说明钛合金骨小梁具有较高的拉伸强度;②3D打印钛合金骨小梁拉伸试件实验与数值模拟实验均显示,骨小梁试件受到拉伸破坏时的破坏形式为丝径断裂,不会在骨小梁与钛合金实体的结合面发生断裂;③数值模拟实验中骨小梁试件的拉伸破坏载荷低于3D打印钛合金骨小梁拉伸试件,造成该差异的原因主要为:3D打印骨小梁试件的丝径(280-350 μm之间)大于骨小梁的理论丝径(142 μm),而孔径(孔隙率75%)小于骨小梁的理论孔径(孔隙率96%)。

ORCID: 0000-0001-7000-2093(张兰)

中国组织工程研究杂志出版内容重点:生物材料;骨生物材料; 口腔生物材料; 纳米材料; 缓释材料; 材料相容性;组织工程

中图分类号: