Chinese Journal of Tissue Engineering Research ›› 2017, Vol. 21 ›› Issue (18): 2934-2639.doi: 10.3969/j.issn.2095-4344.2017.18.023

Previous Articles Next Articles

Current development and clinical application of pancreatic stents

Wang Jiang, Liu Kai

- Department of Hepatobiliary and Pancreatic Surgery, No. 1 Hospital of Jilin University, Changchun 130021, Jilin Province, China

-

Received:2017-05-08Online:2017-06-28Published:2017-07-07 -

Contact:Liu Kai, Associate professor, Master’s supervisor, Department of Hepatobiliary and Pancreatic Surgery, No. 1 Hospital of Jilin University, Changchun 130021, Jilin Province, China -

About author:Wang Jiang, Studying for master’s degree, Department of Hepatobiliary and Pancreatic Surgery, No. 1 Hospital of Jilin University, Changchun 130021, Jilin Province, China -

Supported by:a grant from the Jilin Provincial Development and Reform Commission, No. 2013C023-6

CLC Number:

Cite this article

Wang Jiang, Liu Kai. Current development and clinical application of pancreatic stents[J]. Chinese Journal of Tissue Engineering Research, 2017, 21(18): 2934-2639.

share this article

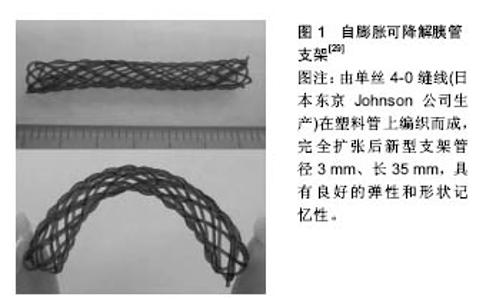

2.1 塑料胰管支架 目前,塑料胰管支架在临床上得到广泛应用,具有稳定性好、排斥性低等优点,不可否认,传统塑料胰管支架可改善慢性胰腺炎患者胰管狭窄所引发的腹痛等一系列症状,但其仍然存在不能适应胰管生理弯曲以及后期需要再次手术取出等弊端。 从胰腺的解剖角度来看,主胰管在胰体至胰头部的部分多弯曲走形,传统的直型胰管支架置入主胰管时需对胰腺组织压迫变形来适应主胰管的走形,期间增加了支架移位的风险,术后近端、远端移位的风险约占5.2%和7.5%[19]。Ishihara等[19]将原有的直型胰管支架改为S型,较直型胰管支架更好地适应胰管生理弯曲,将其成功置入20例症状典型的慢性胰腺炎患者中,术后患者主胰管通畅,腹痛症状缓解,无支架移位等并发症,术后支架估计有效时间为(334.7±30.8) d,S型胰管支架的大胆创新提高了临床医师对胰腺解剖的认识,为胰管支架的研究提供了新思路。 Takao Itoi团队对传统的单猪尾塑料胰管支架进行改造[20],将其称之为新型塑料胰管支架,其总长度为 20 cm,有效使用长度为15 cm;其尖端呈锥形,提高了支架穿过狭窄胰管的能力;于胰管上增加了4个内凸缘(2个在远端和2个在近端)和1个单一的外部尾纤,使得新型塑料胰管更易被固定,明显减少了支架移位风险,加大了引流效果。研究中选取了8例急性胰腺炎后主胰管狭窄或胰肠吻合术后吻合口狭窄的患者,全部成功放置了新型胰管,平均手术时间为37.5 min,术后平均随访时间7.4个月,无支架移位等不良事件发生,仅有1例出现轻微的自限性腹痛,此支架术后疗效肯定。 Boursier等[21]回顾了大量胰管支架手术的案例,总结了胰管支架的两大缺陷:其一,术中整个主胰管不插管;其二,支架缺乏顺应性且缺乏侧孔。为了改善胰管支架的性能,作者设计了一款新型的支架,称之为Johlin®支架(一种新型柔性多侧孔支架,由新型聚氨酯材料合成,末端呈锥形),相比于传统的聚乙烯材料支架具有更加灵活、顺应性更强的特点;其支架侧孔明显减少了炎症反应,达到了更好的引流效果,且不易形成胆盐沉积而堵塞支架,从而增加了支架使用寿命;锥形尖端使得Johlin®支架更易通过主胰管,减少了术中对胰管组织的刮擦损伤;同时,支架规格多样,其有效长度从8 cm至22 cm不等,适应更多人群。为进一步评估Johlin®支架治疗慢性胰腺炎的可行性,Boursier等将其置入31例慢性胰腺炎患者中,其中30例患者腹痛明显好转,2例患者发生支架移位,5例患者支架移除后出现再梗阻。故该新型塑料胰管支架可明显缓解腹痛,治疗慢性胰腺炎所致胰管狭窄是可行的,缺点为该支架需每8-10个月定期更换。 塑料胰管支架因价格低廉且手术操作简单等优点被广泛应用于临床。目前,为使胰管支架更好的亲和胰腺主胰管,减少术后并发症,人们对传统支架创新性改造。改造方向主要体现在:其一,选择顺应性更好的塑料材料;其二:更改塑料支架管型,如直管、S管、猪尾管、凸缘、辅助管孔等。 2.2 自膨胀金属胰管支架 近年来,全覆膜自膨胀金属支架对于慢性胰腺炎的治疗安全性及有效性得到了肯定[22],已经逐渐应用于临床,与塑料支架相比,全覆膜自膨胀金属支架具有置管较易、管径相对较大、通畅时间较长的优点[23]。 Park等[24]设计了一款新型全覆膜自膨胀金属支架,支架所附薄膜由镍钛合金丝和聚四氟乙烯组成,形状呈现为“~”型。与传统塑料支架相比,新型全覆膜自膨胀金属支架管径明显增大,提供持续性的主胰管引流,避免了因胰腺组织通过支架网孔嵌入支架管内而影响胰液引流及拔管困难的风险;然而,不可忽略的是,所附薄膜也会影响侧支胰管的通畅性,增加了胰腺脓毒症或支架诱导性胰腺炎的风险。作者选取了13例慢性胰腺炎患者或行塑料支架治疗后再发腹部疼痛不适的患者,经内镜于胰管内置入全覆膜自膨胀金属支架,术后出现2例轻度胰腺炎、5例支架移位和2例淤胆性肝功能障碍,未发生急性坏死性胰腺炎;于2个月后移除胰管支架,随访见所有患者胰管狭窄症状明显好转。故新型胰管金属支架治疗胰管狭窄有效并且相对安全。 Moon等[25]对以往全覆膜自膨胀金属支架进行了改造,新型的全覆膜自膨胀金属支架两端渐进性膨大;中部呈波浪状,覆以聚四氟乙烯膜,提高了支架的整合性。为了对新型全覆膜自膨胀金属支架进行安全性综合评估,作者选取了32例慢性胰腺炎合并主胰管狭窄患者,内镜下置入全覆膜自膨胀金属支架,所有患者腹痛均得到缓解,无术后胰管支架移位、胰腺炎及胰腺坏死等并发症发生。经3个月随访证实:新型的全覆膜自膨胀金属支架可更好地固定于主胰管内,其棱角可能会损伤主胰管,术后统计这种损伤一般都是轻微的,可自行缓解;另一方面,支架所附薄膜并未影响胰液引流,可能是因为支架并未完全贴敷于管壁,且支架仅支撑于胰腺头部及体部,尾部胰液引流正常,新型的全覆膜自膨胀金属支架可有效治疗慢性胰腺炎所致的主胰管狭窄。 全覆膜金属支架对于治疗慢性胰腺炎所致胰管狭窄常出现支架移位等问题,尤其是远端移位,Ogura 等[26]创新性地在全覆膜金属支架上增加一辅助牵引线,易于移位后支架的取出。作者将此种新型全覆膜金属支架置入1例慢性胰腺炎老年患者主胰管,术后6个月后无支架移位等严重并发症。 全覆膜自膨胀金属支架较传统塑料支架而言具有更大的优势,其提供了更大的支撑直径,引流效果更佳。但全覆膜自膨胀金属支架仍存在诸多缺陷,例如支架易移位、且需二次手术取出。借鉴以上作者对支架改进的新思路和新方法,这些问题可尝试通过更改支架管型或增加辅助工具来得以改善。 2.3 具有生物可降解性的胰管支架 自从1988年Stack等报道了聚乙二醇合成的生物可降解支架应用于血管和尿道支架以来,可降解材料在外科领域中的应用研究已陆续展开。 胰管可降解支架因其在管腔内成形时间短,生物相容性良好,并可在要求时间内完全降解,避免永久支架的不良反应等优点,成为新型胰管支架的开发目标。目前,美国食品和药物管理局批准的可降解人工材料主要有聚丙交酯(PLA)、聚乙交酯(PGA)、聚己内酯(PCL)等。 可降解胰管支架需通过增加硫酸钡含量来提高透视下支架的清晰度,而硫酸钡对胰腺组织的毒性尚无定论,Lamsa等[27]于2006年为评估一种新型可降解胰管内支架(PLA65-BaSO4)置入胰腺组织后的毒性反应,设计了一组对照试验,共选取了65只大鼠,将其开腹置入不同支架,分为新型支架(PLA65-BaSO4)组、惰性钢支架组及空白对照组;21 d后观察各组胰腺组织病理及淀粉酶活性,结果提示可降解支架置入后胰腺炎症反应较轻,与惰性钢支架的毒性作用相似,故作者认为该新型材料(PLA65-BaSO4)可作为胰腺内可降解支架的医用材料,有望广泛应用于临床。 面对传统的胰管支架管径小且需术后二次取管等缺点,Laukkarinen等[28]于2008年开发出新型可生物降解的自膨胀胰管支架(厚0.25 mm,长20 mm,最大膨胀直径35 mm,并加入23%的硫酸钡成分,可在X射线下明显成像),该支架提供了较大管径并可在规定时间内降解。为评价新型支架的降解率、胰管的通畅性和支架的组织学变化,作者选取4只猪作为研究对象,切开其十二指肠经乳头置入胰管支架,术后观察所有猪无明显不良反应,淀粉酶于1,3,6个月复查与术前无差异性,X射线下透视见胰管支架1个月后全显影,3个月后未见显影,6个月后观察置管处与术前无明显差异,镜下病理仅提示轻度炎性反应,可忽略不计,新型支架提供足够的径向力支撑胰腺狭窄段。该实验充分说明新型胰腺支架的安全性较高。作者选取大型动物进行新型可降解支架的实验,实验数据充分说明该型胰管支架的有效性,为进入临床试验奠定了基础。 面对自膨胀金属支架置入术后支架移位或取架困难的问题,Itoi等[29]于2012年手制了自膨胀可降解胰管支架,由单丝4-0缝线(日本东京Johnson公司生产)在塑料管上编织而成,完全扩张后新型支架管径3 mm、长35 mm,具有良好的弹性和形状记忆性(图1),可膨胀直径超过原始支架的98%,临床应用试验显示此支架抗压强度可维持3周左右。所有支架全部安全稳定地置入4个实验猪的胰、胆管内,动物尸检提示所有支架均位于胰管内,作者认为猪模型胰管内使用新型支架是可行的,但该支架存在最主要问题是无法X射线下透视,且需进一步动物实验评估支架的短期通畅性、组织反应性及可降解程度,未来该可降解支架有希望广泛应用于临床,如:ERCP术后胰腺炎、术后胰瘘、外伤性胰管断裂等。"

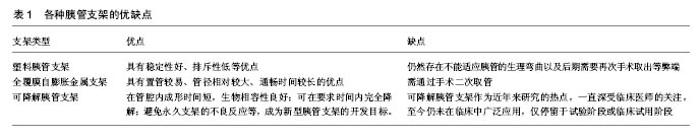

Nordback等[30]于2012年设计了一款新型可降解胰管支架,由聚乳酸构成,掺入一部分X射线下透视可显影的硫酸钡,由于设备上的缺乏、临床内镜及经皮穿刺的禁用,通过胰肠吻合术于29例患者使用新型可降解胰管支架,观察新型可降解支架的降解速率、吻合口通畅度、组织毒性等,进行1年的临床Ⅰ期观察,总结出:新型支架可在人体内3个月完全降解,其中57%的患者胰管通畅度良好,43%的患者出现不同程度的胰管狭窄,并未显示新型支架的早期风险,表现出良好的生物相容性。目前为止,仍未有相关可降解支架用于消化道应用的临床研究,此文关于新型可降解胰管支架临床研究开创了新纪元,为临床推广提供了重要的理论基础。 新型可降解自膨胀式胰管支架因其优越的性能深受临床医师的关注,但从未在临床工作中开展,Cahen等[31]于2015年选取了7例慢性胰腺炎所致纤维化胰管狭窄患者,成功置入一种新型可降解非覆膜自膨胀胰管支架(直径6 mm,长3.0-4.0 mm,预期降解时间为3-6个月),取得良好的临床表现,6个月后所有患者行ERCP术,发现体内支架完全降解,其中1例患者3个月后行二次置入塑料支架,2例患者接受手术治疗,其余4例患者1年内胰管狭窄明显缓解,作者认为新型可降解非覆膜自膨胀胰管支架可明显缓解慢性胰腺炎胰管狭窄,短期内可完全降解,操作上简易安全。 可降解胰管支架作为近年来研究的热点,一直深受临床医师的关注,至今仍未在临床中广泛应用,仅停留于实验阶段或临床试用阶段,但其临床前景十分可观,由起始的动物模型到如今的临床试用已取得长足的进步,新型胰管支架未来可能成为内镜下胰管支架的明星产品。 3种胰管支架的优缺点见表1。 2.4 胰管支架的展望 新型可降解胰管支架材料研究蓬勃发展,相比于传统材料(塑料、金属),未来的胰管支架材料既要提供足够的支撑力以缓解胰管梗阻症状,同时也应提供胰管稳定的可降解性,保证支架的弹性和生物相容性。 现代支架材料的研究相对热门,其中主要有2个方向:①对传统支架材料进行再开发利用,主要包括天然的生物材料(氨基酸类聚合物、壳聚糖等[32])、合成有机高分子材料(聚氨基酸、聚乳酸等)及复合材料;②可通过生物材料表面修饰对原有支架进行二次处理,使支架材料具有更好的细胞亲和性并且可衍生出新型产品[33-34]。 迄今为止,理想的胰管支架材料仍有待于研究,许多问题需进一步解决,但随着医学生物学及分子生物学的发展,微观粒子研究水平不断提高,支架材料的研究有望取得质的飞跃。 "

| [1]中华医学会外科学分会胰腺外科学组. 慢性胰腺炎诊治指南(2014)[J]. 中华外科杂志, 2015, 14(4):277-282. [2]郑舒丹. 50例慢性胰腺炎患者的临床病例分析与病例对照研究[J]. 医学信息, 2015,(36):301.[3]王洛伟, 李兆申, 李淑德,等. 慢性胰腺炎全国多中心流行病学调查[J]. 中华胰腺病杂志, 2007, 7(1):1-5.[4]朱雨田, 陈和平. 慢性胰腺炎遗传学研究进展[J]. 实用医院临床杂志,2016,13(1):125-127.[5]Talukdar R, Nageshwar Reddy D. Endoscopic therapy for chronic pancreatitis. Curr Opin Gastroenterol. 2014;30(5): 484-489. [6]Clarke B, Slivka A, Tomizawa Y, et al. Endoscopic therapy is effective for patients with chronic pancreatitis. Clin Gastroenterol Hepatol. 2012;10(7):795-802.[7]闫峻, 刘建生. 慢性胰腺炎的外科治疗进展[J]. 中国药物与临床, 2015, 18(8):329-331. [8]杨柳, 张金坤, 周春晓. 治疗性经内镜逆行胰胆管造影在慢性胰腺炎患者中的应用[J]. 临床肝胆病杂志, 2015,31(5): 684-686. [9]Nadkarni NA, Kotwal V, Sarr MG, et al. Disconnected Pancreatic Duct Syndrome: Endoscopic Stent or Surgeon's Knife. Pancreas. 2015;44(1):16-22.[10]文卫, 王敏, 范志宁. 胰管支架留置技术在胆管深插管中的应用[J]. 中国内镜杂志, 2010, 16(9):961-963.[11]Shi QQ, Ning XY, Zhan LL, et al. Placement of prophylactic pancreatic stents to prevent post-endoscopic retrograde cholangiopancreatography pancreatitis in high-risk patients: a meta-analysis. World J Gastroenterol. 2014;20(22):7040- 7048.[12]Kawaguchi Y, Ogawa M, Omata F, et al. Randomized controlled trial of pancreatic stenting to prevent pancreatitis after endoscopic retrograde cholangiopancreatography. World J Gastroenterol. 2012;18(14):1635-1641.[13]钱阳阳, 赵朕华, 廖专,等. ERCP术后胰腺炎的最新研究进展[J]. 中华胰腺病杂志, 2016, 16(3):206-210.[14]周洪, 叶博, 叶萍,等. 内镜下胰管支架置入术治疗胰腺分裂症16例[J]. 上海医学, 2012, 35(12):1047-1049.[15]Qin Z, Linghu EQ. Temporary placement of a fully covered self-expandable metal stent in the pancreatic duct for aiding extraction of large pancreatic duct stones: preliminary data. Eur J Gastroenterol Hepatol. 2014;26(11):1273-1277.[16]Andriulli A, Loperfido S, Napolitano G, et al. Incidence rates of post-ERCP complications: a systematic survey of prospective studies. Am J Gastroenterol. 2007;102(8):1781-1788.[17]Kawaguchi Y, Lin JC, Kawashima Y, et al. Risk factors for migration, fracture, and dislocation of pancreatic stents. Gastroenterol Res Pract. 2015;2015:365457.[18]李秋果. 组织工程支架材料研究进展及发展前景[J]. 长江大学学报:自然科学版, 2012, 9(2):21-25.[19]Ishihara T, Yamaguchi T, Seza K, et al. Efficacy of s-type stents for the treatment of the main pancreatic duct stricture in patients with chronic pancreatitis. Scand J Gastroenterol. 2006;41(6):744-750.[20]Itoi T, Sofuni A, Tsuchiya T, et al. Initial evaluation of a new plastic pancreatic duct stent for endoscopic ultrasonography-guided placement. Endoscopy. 2015; 47(5): 462-465.[21]Boursier J, Quentin V, Le Tallec V, et al. Endoscopic treatment of painful chronic pancreatitis: evaluation of a new flexible multiperforated plastic stent. Gastroenterol Clin Biol. 2008;32(10):801-805.[22]Giacino C, Grandval P, Laugier R. Fully covered self-expanding metal stents for refractory pancreatic duct strictures in chronic pancreatitis. Endoscopy. 2012;44(9): 874-877.[23]Shen Y, Liu M, Chen M, et al. Covered metal stent or multiple plastic stents for refractory pancreatic ductal strictures in chronic pancreatitis: a systematic review. Pancreatology. 2014;14(2):87-90.[24]Park DH, Kim MH, Moon SH, et al. Feasibility and safety of placement of a newly designed, fully covered self-expandable metal stent for refractory benign pancreatic ductal strictures: a pilot study (with video). Gastrointest Endosc. 2008;68(6): 1182-1189.[25]Moon SH, Kim MH, Park DH, et al. Modified fully covered self-expandable metal stents with antimigration features for benign pancreatic-duct strictures in advanced chronic pancreatitis, with a focus on the safety profile and reducing migration. Gastrointest Endosc. 2010;72(1):86-91.[26]Ogura T, Kurisu Y, Yamamoto K, et al. Placement of a novel fully covered metallic stent for refractory pancreatic duct stricture. Endoscopy. 2015;47 Suppl 1 UCTN:E206-207.[27]Lämsä T, Jin H, Mikkonen J, et al. Biocompatibility of a new bioabsorbable radiopaque stent material (BaSO4 containing poly-L,D-lactide) in the rat pancreas. Pancreatology. 2006; 6(4):301-305.[28]Laukkarinen J, Lämsä T, Nordback I, et al. A novel biodegradable pancreatic stent for human pancreatic applications: a preclinical safety study in a large animal model. Gastrointest Endosc. 2008;67(7):1106-1112.[29]Itoi T, Kasuya K, Abe Y, et al. Endoscopic placement of a new short-term biodegradable pancreatic and biliary stent in an animal model: a preliminary feasibility study (with videos).J Hepatobiliary Pancreat Sci. 2011;18(3):463-467.[30]Nordback I, Räty S, Laukkarinen J, et al. A novel radiopaque biodegradable stent for pancreatobiliary applications--the first human phase I trial in the pancreas. Pancreatology. 2012; 12(3):264-271.[31]Cahen DL, Merwe SVD, Poley JW, et al. A Novel Biodegradable Non-Covered Self-Expandable Stent to Treat Pancreatic Duct Strictures in Chronic Pancreatitis; a Pilot Study. Gastrointestinal Endoscopy. 2015; 81(5):AB143- AB144.[32]Rafique A, Mahmood Zia K, Zuber M, et al. Chitosan functionalized poly(vinyl alcohol) for prospects biomedical and industrial applications: A review. Int J Biol Macromol. 2016;87:141-154.[33]Ma F, Chen S, Liu P, et al. Improvement of β-TCP/PLLA biodegradable material by surface modification with stearic acid. Mater Sci Eng C Mater Biol Appl. 2016;62:407-413.[34]Inam Ul Ahad, Bartnik A, Fiedorowicz H, et al. Surface modification of polymers for biocompatibility via exposure to extreme ultraviolet radiation. J Biomed Mater Res A. 2014; 102(9):3298-3310. |

| [1] | Yao Xiaoling, Peng Jiancheng, Xu Yuerong, Yang Zhidong, Zhang Shuncong. Variable-angle zero-notch anterior interbody fusion system in the treatment of cervical spondylotic myelopathy: 30-month follow-up [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(9): 1377-1382. |

| [2] | An Weizheng, He Xiao, Ren Shuai, Liu Jianyu. Potential of muscle-derived stem cells in peripheral nerve regeneration [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(7): 1130-1136. |

| [3] | Zhang Jinglin, Leng Min, Zhu Boheng, Wang Hong. Mechanism and application of stem cell-derived exosomes in promoting diabetic wound healing [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(7): 1113-1118. |

| [4] | He Yunying, Li Lingjie, Zhang Shuqi, Li Yuzhou, Yang Sheng, Ji Ping. Method of constructing cell spheroids based on agarose and polyacrylic molds [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(4): 553-559. |

| [5] | He Guanyu, Xu Baoshan, Du Lilong, Zhang Tongxing, Huo Zhenxin, Shen Li. Biomimetic orientated microchannel annulus fibrosus scaffold constructed by silk fibroin [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(4): 560-566. |

| [6] | Yang Feng, Zhao Qian, Zhang Shixuan, Zhao Tienan, Feng Bo. Effectiveness and safety of rapamycin combined with CD133 antibody stent in preventing vascular restenosis [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(4): 579-584. |

| [7] | Chen Xiaoxu, Luo Yaxin, Bi Haoran, Yang Kun. Preparation and application of acellular scaffold in tissue engineering and regenerative medicine [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(4): 591-596. |

| [8] | Kang Kunlong, Wang Xintao. Research hotspot of biological scaffold materials promoting osteogenic differentiation of bone marrow mesenchymal stem cells [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(4): 597-603. |

| [9] | Shen Jiahua, Fu Yong. Application of graphene-based nanomaterials in stem cells [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(4): 604-609. |

| [10] | Zhang Tong, Cai Jinchi, Yuan Zhifa, Zhao Haiyan, Han Xingwen, Wang Wenji. Hyaluronic acid-based composite hydrogel in cartilage injury caused by osteoarthritis: application and mechanism [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(4): 617-625. |

| [11] | Li Hui, Chen Lianglong. Application and characteristics of bone graft materials in the treatment of spinal tuberculosis [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(4): 626-630. |

| [12] | Gao Cangjian, Yang Zhen, Liu Shuyun, Li Hao, Fu Liwei, Zhao Tianyuan, Chen Wei, Liao Zhiyao, Li Pinxue, Sui Xiang, Guo Quanyi. Electrospinning for rotator cuff repair [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(4): 637-642. |

| [13] | Guan Jian, Jia Yanfei, Zhang Baoxin , Zhao Guozhong. Application of 4D bioprinting in tissue engineering [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(3): 446-455. |

| [14] | Liu Jiali, Suo Hairui, Yang Han, Wang Ling, Xu Mingen. Influence of lay-down angles on mechanical properties of three-dimensional printed polycaprolactone scaffolds [J]. Chinese Journal of Tissue Engineering Research, 2022, 10(16): 2612-2617. |

| [15] | Huang Bo, Chen Mingxue, Peng Liqing, Luo Xujiang, Li Huo, Wang Hao, Tian Qinyu, Lu Xiaobo, Liu Shuyun, Guo Quanyi . Fabrication and biocompatibility of injectable gelatin-methacryloyl/cartilage-derived matrix particles composite hydrogel scaffold [J]. Chinese Journal of Tissue Engineering Research, 2022, 10(16): 2600-2606. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||