Chinese Journal of Tissue Engineering Research ›› 2019, Vol. 23 ›› Issue (36): 5824-5829.doi: 10.3969/j.issn.2095-4344.1994

Previous Articles Next Articles

Digital design of personalized scoliosis orthopedic braces based on 3D printing technology

- 1Dalian Jiaotong University, Dalian 116000, Liaoning Province, China; 2Department of Imaging, Zhengzhou Orthopaedic Hospital, Zhengzhou 450000, Henan Province, China; 3The People’s Hospital of Hebi, Hebi 458000, Henan Province, China

-

Online:2019-12-28Published:2019-12-28 -

Contact:Guan Tianmin, PhD, Professor, Doctoral supervisor, Dalian Jiaotong University, Dalian 116000, Liaoning Province, China -

About author:Zhang Yufang, Doctoral candidate, Dalian Jiaotong University, Dalian 116000, Liaoning Province, China

CLC Number:

Cite this article

Zhang Yufang, Guan Tianmin, Guo Qiaoge, Zhang Yufen, Guo Yanli. Digital design of personalized scoliosis orthopedic braces based on 3D printing technology[J]. Chinese Journal of Tissue Engineering Research, 2019, 23(36): 5824-5829.

share this article

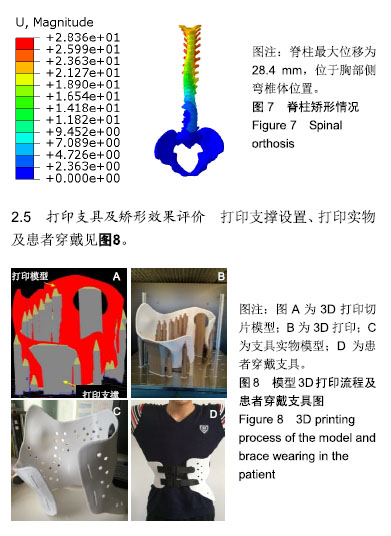

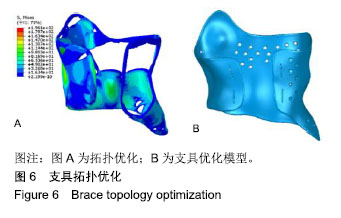

2.4 支具拓扑优化 此次研究采用Abaqus 6.14-2有限元软件中的优化模块进行拓扑优化。优化区域为整个支具模型,目标函数为Min F(x1,x2,x3,…,xn),其中F=weight, x1,x2,x3,…,xn为力学参数。在满足支具的刚度要求条件下,优化质量和体积,达到最佳材料分布。冻结支具的轮廓边界及施力位置,防止其在优化过程中产生破坏。分别设置10组优化参数(0.15,0.2,0.25,0.3,0.35,0.4,0.45,0.5,0.55,0.6),通过45次迭代运算,达到满足优化目标的收敛状态。对比优化结果,选取优化参数为0.4。依据有限元优化结果,在满足刚度要求且不影响矫形效果的区域,通过布尔运算对支具减材处理。此次研究为方便3D打印操作,在减材区域修剪直径为8.5 mm的圆形孔,不仅增加了透气性,而且减少了材料的消耗,在实际临床诊治中,修剪材料的图形可根据患者要求个性化设计[24]。优化过程及模型效果见图6。"

| [1]Rigo M, Jela?i? M. Brace technology thematic series: the 3D Rigo Chêneau-type brace. Scoliosis Spinal Disord. 2017;12:10. [2]Çolak TK, Akgül T, Çolak I, et al. Health related quality of life and perception of deformity in patients with adolescent idiopathic scoliosis. J Back Musculoskelet Rehabil. 2017;30(3):597-602. [3]Han J, Xu Q, Yang Y, et al. Evaluation of quality of life and risk factors affecting quality of life in adolescent idiopathic scoliosis.. Intractable Rare Dis Res. 2015;4(1):12-16.[4]Schwieger T, Campo S, Weinstein SL, et al. Body image and quality-of-life in untreated versus brace-treated females with adolescent idiopathic scoliosis. Spine. 2015;41(4):311-319.[5]Xu L, Li Y, Sheng F, et al. The efficacy of brace treatment for thoracolumbar kyphosis in patients with achondroplasia. Spine. 2018; 43(16):1133-1138.[6]Chalmers E, Lou E, Hill D, et al. An advanced compliance monitor for patients undergoing brace treatment for idiopathic scoliosis. Med Eng Phys. 2015; 37(2):203-209.[7]Karol L A, Virostek D, Felton K, et al. Effect of compliance counseling on brace use and success in patients with adolescent idiopathic scoliosis. J Bone Joint Surg. 2016; 98(1):9-14.[8]Poscia A, Aulisa AG, Marzetti E, et al. Correlation between compliance and brace treatment in juvenile and adolescent idiopathic scoliosis: SOSORT 2014 award winner. Scoliosis. 2014;9(1):1-9.[9]Lou EHM, Hill DL, Raso JV, et al. How quantity and quality of brace wear affect the brace treatment outcomes for AIS. Eur Spine J. 2016; 25(2):495-499.[10]Weiss HR, Nan XF, Moramarco M, et al. Bracing Scoliosis - State of the Art (Mini-Review). Curr Pediatr Rev. 2016;12(1):36-42.[11]Herget GW, Patermann S, Strohm PC, et al. Spinal Orthoses: The Crucial Role of Comfort on Compliance of Wearing - Monocentric Prospective Pilot Study of Randomized Cross-Over Design. Acta Chir Orthop Traumatol Cech. 2017;2:91-96.[12]黄亚翔,赵自平,王治国,等.夜用型脊柱侧弯矫形支具的数字化设计[J].中国组织工程研究,2018,22(27):4327-4331.[13]Weiss HR, Tournavitis N, Nan X, et al. Workflow of CAD/CAM scoliosis brace adjustment in preparation using 3d printing. Open Med Inform J. 2017;11(1):44-51.[14]Jr CF. Adolescent idiopathic scoliosis, bracing, and the Hueter- Volkmann principle. Spine J. 2003; 3(3):180-185.[15]钟环,欧阳汉斌,魏波,等.桡骨远端骨折锁定钢板的拓扑优化及有限元分析[J]. 中国矫形外科杂志,2018,26(23):2189-2194.[16]Tack P, Victor J, Gemmel P, et al. 3D-printing techniques in a medical setting: a systematic literature review. Biomed Eng Online. 2016;15(1): 115.[17]张爱平,刘羲,刘志峰,等. 基于3D打印的定制脊柱侧弯矫形器设计制造与舒适度评价[J]. 北京工业大学学报, 2017,43(4):518-525.[18]Du HG, Liao SH, Jiang Z, et al. Biomechanical analysis of press-extension technique on degenerative lumbar with diodeling of brace treatment of scoliosis: effects of gravitational loads. Medical & biological engineerisc herniation and staggered facet joint. Saudi Pharmaceutical J. 2016; 24(3):305-311.[19]Wang L, Zhang B, Chen S, et al. A validated finite element analysis of facet joint stress in degenerative lumbar scoliosis. World Neurosurg. 2016; 95:126-133.[20]Périé D, Aubin CE, Petit Y, et al. Personalized biomechanical simulations of orthotic treatment in idiopathic scoliosis . Clin Biomech. 2004;19(2):190.[21]Aubin CE, Dansereau J, De Guise JA, et al. A study of biomechanical coupling between spine and rib cage in the treatment by orthosis of scoliosis. Ann Chir. 1996;50(8):641.[22]Cheung JPY, Yiu KKL, Vidyadhara S, et al. Predictability of supine radiographs for determining in-brace correction for adolescent idiopathic scoliosis. Spine. 2017;43(14):971-974.[23]Ekici G, Unal E, Akbayrak T, et al. Effects of active/passive interventions on pain, anxiety and quality of life in women with fibromyalgia: randomized controlled pilot trial. Women Health. 2016; 57(1):88-107.[24]Lin H, Shi L, Wang D. A rapid and intelligent designing technique for patient-specific and 3D-printed orthopedic cast. 3d Printing Med. 2016; 2(1):7-17.[25]Wong MS. Computer-aided design and computer-aided manufacture (CAD/CAM) system for construction of spinal orthosis for patients with adolescent idiopathic scoliosis. Physiother Theory Pract. 2011;27(1): 74-79.[26]Sattout A, Clin J, Cobetto N, et al. Biomechanical assessment of providence nighttime brace for the treatment of adolescent idiopathic scoliosis. Spine Deform. 2016;4(4):253-260.[27]Cobetto N, Aubin, CE, Parent S, et al. 3D correction of AIS in braces designed using CAD/CAM and FEM: a randomized controlled trial. Scoliosis Spinal Disord. 2017;12:24.[28]杨新宇,詹成,李明,等.3D打印技术在医学中的应用进展[J].复旦学报(医学版),2016,43(4):490-494.[29]Berman B. 3-D printing: The new industrial revolution. Business Horizons. 2012;55(2): 162.[30]Khajavi SH, Holmström J, Partanen J. Additive manufacturing in the spare parts supply chain. Comput Industry. 2013;65(1):50-63.[31]陈拥,王增辉,朴成哲. 3D打印个性化截骨导板辅助行全膝关节置换的应用[J]. 中国组织工程研究, 2019, 23(8):1155-1160.[32]Santos S, Soares B, Leite M, et al. Design and development of a customised knee positioning orthosis using low cost 3D printers. Virt Phys Protot. 2017:1-11.[33]Khodaei B, Saeedi H, Jalali M, et al. Comparison of plantar pressure distribution in CAD-CAM and prefabricated foot orthoses in patients with flexible flatfeet. Foot. 2017;33:76-80.[34]Geoffroy M, Gardan J, Goodnough J, et al. Cranial remodeling orthosis for infantile plagiocephaly created through a 3d scan, topological optimization, and 3d printing process. J Prosthet Orthot. 2018;1(1): 201-209.陆亮亮,史廷春,于云,等.3D打印指骨骨折支具的研究[J].航天医学与医学工程, 2017,30(4):30-37. |

| [1] | Xu Feng, Kang Hui, Wei Tanjun, Xi Jintao. Biomechanical analysis of different fixation methods of pedicle screws for thoracolumbar fracture [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(9): 1313-1317. |

| [2] | Lu Dezhi, Mei Zhao, Li Xianglei, Wang Caiping, Sun Xin, Wang Xiaowen, Wang Jinwu. Digital design and effect evaluation of three-dimensional printing scoliosis orthosis [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(9): 1329-1334. |

| [3] | Zhang Tongtong, Wang Zhonghua, Wen Jie, Song Yuxin, Liu Lin. Application of three-dimensional printing model in surgical resection and reconstruction of cervical tumor [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(9): 1335-1339. |

| [4] | Chen Xinmin, Li Wenbiao, Xiong Kaikai, Xiong Xiaoyan, Zheng Liqin, Li Musheng, Zheng Yongze, Lin Ziling. Type A3.3 femoral intertrochanteric fracture with augmented proximal femoral nail anti-rotation in the elderly: finite element analysis of the optimal amount of bone cement [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(9): 1404-1409. |

| [5] | Zhou Jihui, Li Xinzhi, Zhou You, Huang Wei, Chen Wenyao. Multiple problems in the selection of implants for patellar fracture [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(9): 1440-1445. |

| [6] | Xu Yulin, Shen Shi, Zhuo Naiqiang, Yang Huilin, Yang Chao, Li Yang, Zhao Heng, Zhao Lu. Biomechanical comparison of three different plate fixation methods for acetabular posterior column fractures in standing and sitting positions [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(6): 826-830. |

| [7] | Cai Qunbin, Zou Xia, Hu Jiantao, Chen Xinmin, Zheng Liqin, Huang Peizhen, Lin Ziling, Jiang Ziwei. Relationship between tip-apex distance and stability of intertrochanteric femoral fractures with proximal femoral anti-rotation nail: a finite element analysis [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(6): 831-836. |

| [8] | Liu Zhengpeng, Wang Yahui, Zhang Yilong, Ming Ying, Sun Zhijie, Sun He. Application of 3D printed interbody fusion cage for cervical spondylosis of spinal cord type: half-year follow-up of recovery of cervical curvature and intervertebral height [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(6): 849-853. |

| [9] | Song Chengjie, Chang Hengrui, Shi Mingxin, Meng Xianzhong. Research progress in biomechanical stability of lateral lumbar interbody fusion [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(6): 923-928. |

| [10] | Xie Chongxin, Zhang Lei. Comparison of knee degeneration after anterior cruciate ligament reconstruction with or without remnant preservation [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(5): 735-740. |

| [11] | Xu Junma, Yu Yuechao, Liu Zhi, Liu Yu, Wang Feitong. Application of 3D-printed coplanar template combined with fixed needle technique in percutaneous accurate biopsy of small pulmonary nodules [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(5): 761-764. |

| [12] | Wu Zijian, Hu Zhaoduan, Xie Youqiong, Wang Feng, Li Jia, Li Bocun, Cai Guowei, Peng Rui. Three-dimensional printing technology and bone tissue engineering research: literature metrology and visual analysis of research hotspots [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 564-569. |

| [13] | Nie Shaobo, Li Jiantao, Sun Jien, Zhao Zhe, Zhao Yanpeng, Zhang Licheng, Tang Peifu. Mechanical stability of medial support nail in treatment of severe osteoporotic intertrochanteric fracture [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(3): 329-333. |

| [14] | Tan Jiachang, Yuan Zhenchao, Wu Zhenjie, Liu Bin, Zhao Jinmin. Biomechanical analysis of elastic nail combined with end caps and wire fixation for long oblique femoral shaft fractures [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(3): 334-338. |

| [15] | Chen Lu, Zhang Jianguang, Deng Changgong, Yan Caiping, Zhang Wei, Zhang Yuan. Finite element analysis of locking screw assisted acetabular cup fixation [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(3): 356-361. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||