Chinese Journal of Tissue Engineering Research ›› 2019, Vol. 23 ›› Issue (14): 2215-2222.doi: 10.3969/j.issn.2095-4344.1641

Previous Articles Next Articles

Physical properties and biocompatibility of 3D printed bone microparticle/poly(lactic-co-glycolic acid) scaffold

Zhang Minbo, Peng Qifeng, Ma Yaping, Kong Weijun, Liao Wenbo

- Department of Spinal Surgery, Affiliated Hospital of Zunyi Medical University, Zunyi 563000, Guizhou Province, China

-

Contact:Liao Wenbo, Department of Spinal Surgery, Affiliated Hospital of Zunyi Medical University, Zunyi 563000, Guizhou Province, China -

About author:Zhang Minbo, Master candidate, Department of Spinal Surgery, Affiliated Hospital of Zunyi Medical University, Zunyi 563000, Guizhou Province, China -

Supported by:Zunyi City Honghuagang District Science and Technology Project, No. (2016)09 (to LWB)

CLC Number:

Cite this article

Zhang Minbo, Peng Qifeng, Ma Yaping, Kong Weijun, Liao Wenbo. Physical properties and biocompatibility of 3D printed bone microparticle/poly(lactic-co-glycolic acid) scaffold[J]. Chinese Journal of Tissue Engineering Research, 2019, 23(14): 2215-2222.

share this article

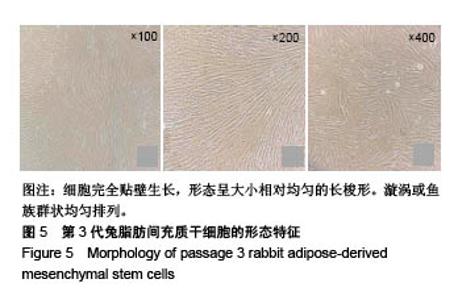

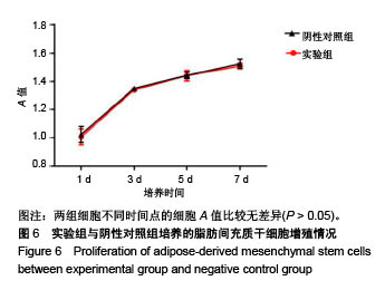

| [1] 金灿,陈振琦.应用3D打印技术制作组织工程支架:修复骨缺损的研究回顾[J].中国组织工程研究,2017,21(10):1611-1616.[2] 周思佳,姜文学,尤佳.骨缺损修复材料:现状与需求和未来[J].中国组织工程研究, 2018, 22(14):2251-2258.[3] Lomas R,Chandrasekar A,Board TN.Bone allograft in the U.K.: perceptions andrealities.Hip Int. 2013;23(5):427-433.[4] Kuroda S,Katayama A,Takano -Yamamoto T.Severe anterior open-bite case treated using titanium screw anchorage.Angle Orthod.2004;74(4):558-567.[5] Yuan J,Zhen P,Zhao HB,et al.The preliminary performance study of the 3D printing of a tricalcium phosphate scaffold for the loading of sustained release anti-tuberculosis drugs.Mater Sci.2015;50(5):2138-2147.[6] Zhang Z,Zhang R,Song Z.Skull defect reconstruction based on a new hybrid level set. Biomed Mater Eng. 2014;24(6): 3343-3351.[7] Guarino V,Ambrosio L.Temperature-driven processing techniques for manufacturing fully interconnected porous scaffolds in bone tissue engineering.Proc Inst Mech Eng H. 2010;224(12):1389-1400.[8] 谢光友,杨海涛,吕富荣,等.兔脂肪间充质干细胞的培养鉴定及体外磁标记MR成像[J].第三军医大学学报,2014,36(15):1567-1571.[9] 国家技术监督局发布.中华人民共和国国家标准GB/T 1568-1997[M].北京:中国标准出版社,1997.[10] Sears NA,Dhavalikar PS,Seshadri D,et al.A Review of Three-Dimensional Printing in Tissue Engineering.Tissue Eng Part B Rev.2016;22(4):298-310.[11] 周晓,盛小伍,曾勇.骨组织工程的研究进展和面临的问题[J].组织工程与重建外科杂志,2016,12(5):319-321.[12] Turnbull G,Clarke J,Picard F,et al.3D bioactive composite scaffolds for bone tissue engineering. Bioact Mater. 2018;3(3): 278-314.[13] Lee M,Wu BM.Recent advances in 3D printing of tissue engineering scaffolds.Methods Mol Biol.2012;868:257-267.[14] 林楷丰,何树,宋岳,等.无丝3D打印技术常温构建仿生人工骨支架的研究[J].中华创伤骨科杂志,2016, 18(5):421-427.[15] Akbarzadeh R,Yousefi AM.Effects of processing parameters in thermally induced phase separation technique on porous architecture of scaffolds for bone tissue engineering. J Biomed Mater Res B Appl Biomater.2014;102(6):1304-1135.[16] Murphy SV,Atala A.3D bioprinting of tissues and organs.Nat Biotechnol.2014;32(8):773-785.[17] Nguyen DT,Mccanless JD,Mecwan MM,et al.Balancing mechanical strength with bioactivity in chitosan-calcium phosphate 3D microsphere scaffolds for bone tissue engineering: air-vs. freeze-drying processes.J Biomater Sci Polym Ed.2013;24(9):1071-1083.[18] Wu C,Luo Y,Cuniberti G,et al.Three-dimensional printing of hierarchical and tough mesoporous bioactive glass scaffolds with a controllable pore architecture, excellent mechanical strength and mineralization ability.Acta Biomater. 2011;7(6): 2644-2650.[19] Nakayama Y,Takewa Y,Sumikura H,et al.In-body tissue - engineered aorticivalve(Biovalve type VII) architecture based on 3D printer molding.J Biomed mater Res B ApplBiomater. 2015;103(1):1-11.[20] 武成聪,王芳,荣树,等.3D打印应用在骨组织工程研究中的特点与进展[J].中国组织工程研究,2017, 21(15):2418-2423.[21] Fafenrot S,Grimmelsmann N,Wortmann M,et al. Three-Dimensional (3D) Printing of Polymer-Metal Hybrid Materials by Fused Deposition Modeling. Materials(Basel). 2017;10(10):1199.[22] Rosenzweig DH,Caredli E,Steffe T,et al.3D PrintedABS and PLA Scaffolds for Cartilage and NucleusPulposus Tissue Regeneration.Int J Mol Sci.2015;16(7):15118-15135.[23] Cao T,Ho KH,Teoh SH.Scaffold design and in vitro study of osteochondralcoculture in a three-dimensional porous polycaprolactone scaffold fabricated by fused deposition modeling. Tissue Eng.2003;9 Suppl 1(supplement 1):S103.[24] 彭齐峰.3D打印骨粉聚乳酸骨组织工程支架的实验研究[D].遵义:遵义医学院,2018.[25] 钱科宏.PLGA介导的多功能复合医用材料的制备及其性能研究[D].扬州:扬州大学,2016.[26] An G,Zhang WB,Ma DK,et al.Influence of VEGF/BMP-2 on the proliferation and osteogenetic differentiation of rat bone mesenchymal stem cells on PLGA/gelatin composite scaffold. Eur Rev Med Pharmacol Sci.2017;21(10):2316-2328.[27] Piao S, Kim IG,LeeJY,et al.Therapeutic effect of adipose-derived stem cells and BDNF-immobilized PLGA membrane in a rat model of cavernous nerve injury.J sex Med. 2012;9(8):1968-1979.[28] Blokhuis TJ,Lindner T.Allograft and bone morphogenetic proteins: an overview.Injury. 2008;39(9):S33-S36.[29] 龙志成,宋兴华,龙仕杰,等.脂肪干细胞复合HA/β-TCP与同种异体骨修复兔脊柱骨缺损的比较[J].中国矫形外科杂志, 2018, 26(2): 164-169.[30] 瞿卫,丁铃,顾龙殿,等.小颗粒同种异体骨微创植骨治疗四肢骨缺损[J].中国骨与关节损伤杂志,2017, 32(9):1000-1001.[31] Zolnik BS,Burgess DJ.Effect of acidic pH on PLGA microsphere degradation and release.J Control Release. 2007;122(3):338-344.[32] Yang Y,Yang S,Wang Y,et al.Anti-infective efficacy, cytocompatibility and biocompatibility of a 3D-printed osteoconductive composite scaffold functionalized with quaternized chitosan.Acta Biomater.2016;46:112-128.[33] Liu C,Li Y,Wang J,et al.Improving Hydrophilicity and Inducing Bone-Like Apatite Formation on PPBES by Polydopamine Coating for Biomedical Application.Molecules. 2018;23(7): 1643.[34] Wilson CJ,Clegg RE,Leavesley DI,et al.Mediation of biomaterial-cell interactions by adsorbed proteins: a review. Tissue Eng.2005;11(2):1-18.[35] Hirasawa M,Tsutsumiarai C,Takakusaki K,et al. Superhydrophilic co-polymer coatings on denture surfaces reduce Candida albicans adhesion-An in vitro study.Arch Oral Biol.2017;87:143.[36] Zhang P, Hamamura K, Yokota H.A brief review of bone adaptation to unloading.Genomics Proteomics Bioinformatics. 2008;6(1):4-7.[37] 周晓,盛小伍,曾勇.骨组织工程的研究进展和面临的问题[J].组织工程与重建外科杂志,2016,12(5):319-321.[38] Rezwan K,Chen QZ,Blaker JJ,et al. Biodegradable and bioactive porous polymer/inorganic composite scaffolds for bone tissue engineering.Biomaterials.2006;27(18):3413-3431.[39] Liu Z,Ji J,Tang S,et al.Biocompatibility, degradability, bioactivity and osteogenesis of mesoporous/macroporous scaffolds of mesoporous diopside/poly(L-lactide) composite.J R Soc Interface.2015;12(111):20150507.[40] Watson BM, Kasper FK, Engel PS,et al.Synthesis and characterization of injectable, biodegradable, phosphate- containing,chemically cross-linkable, thermoresponsivemacromers for bone tissue engineering. Biomacromolecules.2014;15(5):1788-1796.[41] Arrigoni E,de Girolamo L,Di Giancamillo A, et al. Adipose-derived stem cells and rabbit bone regeneration: histomorphometric, immunohistochemical and mechanical characterization. J Orthop Sci.2013;18(2):331-339.[42] Tevlin R,Walmsley GG,Marecic O,et al. Stem and progenitor cells: advancing bone tissue engineering.Drug Deliv Transl Res.2016;6(2):1-15. |

| [1] | Zhang Tongtong, Wang Zhonghua, Wen Jie, Song Yuxin, Liu Lin. Application of three-dimensional printing model in surgical resection and reconstruction of cervical tumor [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(9): 1335-1339. |

| [2] | Zeng Yanhua, Hao Yanlei. In vitro culture and purification of Schwann cells: a systematic review [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(7): 1135-1141. |

| [3] | Xu Dongzi, Zhang Ting, Ouyang Zhaolian. The global competitive situation of cardiac tissue engineering based on patent analysis [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(5): 807-812. |

| [4] | Wu Zijian, Hu Zhaoduan, Xie Youqiong, Wang Feng, Li Jia, Li Bocun, Cai Guowei, Peng Rui. Three-dimensional printing technology and bone tissue engineering research: literature metrology and visual analysis of research hotspots [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 564-569. |

| [5] | Chang Wenliao, Zhao Jie, Sun Xiaoliang, Wang Kun, Wu Guofeng, Zhou Jian, Li Shuxiang, Sun Han. Material selection, theoretical design and biomimetic function of artificial periosteum [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 600-606. |

| [6] | Liu Fei, Cui Yutao, Liu He. Advantages and problems of local antibiotic delivery system in the treatment of osteomyelitis [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 614-620. |

| [7] | Li Xiaozhuang, Duan Hao, Wang Weizhou, Tang Zhihong, Wang Yanghao, He Fei. Application of bone tissue engineering materials in the treatment of bone defect diseases in vivo [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 626-631. |

| [8] | Zhang Zhenkun, Li Zhe, Li Ya, Wang Yingying, Wang Yaping, Zhou Xinkui, Ma Shanshan, Guan Fangxia. Application of alginate based hydrogels/dressings in wound healing: sustained, dynamic and sequential release [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 638-643. |

| [9] | Chen Jiana, Qiu Yanling, Nie Minhai, Liu Xuqian. Tissue engineering scaffolds in repairing oral and maxillofacial soft tissue defects [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 644-650. |

| [10] | Xing Hao, Zhang Yonghong, Wang Dong. Advantages and disadvantages of repairing large-segment bone defect [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(3): 426-430. |

| [11] | Chen Siqi, Xian Debin, Xu Rongsheng, Qin Zhongjie, Zhang Lei, Xia Delin. Effects of bone marrow mesenchymal stem cells and human umbilical vein endothelial cells combined with hydroxyapatite-tricalcium phosphate scaffolds on early angiogenesis in skull defect repair in rats [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(22): 3458-3465. |

| [12] | Wang Hao, Chen Mingxue, Li Junkang, Luo Xujiang, Peng Liqing, Li Huo, Huang Bo, Tian Guangzhao, Liu Shuyun, Sui Xiang, Huang Jingxiang, Guo Quanyi, Lu Xiaobo. Decellularized porcine skin matrix for tissue-engineered meniscus scaffold [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(22): 3473-3478. |

| [13] | Mo Jianling, He Shaoru, Feng Bowen, Jian Minqiao, Zhang Xiaohui, Liu Caisheng, Liang Yijing, Liu Yumei, Chen Liang, Zhou Haiyu, Liu Yanhui. Forming prevascularized cell sheets and the expression of angiogenesis-related factors [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(22): 3479-3486. |

| [14] | Liu Chang, Li Datong, Liu Yuan, Kong Lingbo, Guo Rui, Yang Lixue, Hao Dingjun, He Baorong. Poor efficacy after vertebral augmentation surgery of acute symptomatic thoracolumbar osteoporotic compression fracture: relationship with bone cement, bone mineral density, and adjacent fractures [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(22): 3510-3516. |

| [15] | Liu Liyong, Zhou Lei. Research and development status and development trend of hydrogel in tissue engineering based on patent information [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(22): 3527-3533. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||