Chinese Journal of Tissue Engineering Research

Preparation of magnesium-doped brushite by sintering method

Jia Wan-ping1, Dong Wei2, Peng Hong-feng2, Xu Yan-li2, Wang Hong-mei1, Liang Li-shuo1, Qi Meng-chun2, Liang Yong-qiang1

- 1Department of Orthodontics, 2Department of Maxillofacial Surgery, School of Stomatology, North China University of Science and Technology, Tangshan 063000, Hebei Province, China

-

Received:2018-01-13Online:2018-08-08Published:2018-08-08 -

Contact:Liang Yong-qiang, M.D., Associate professor, Department of Orthodontics, School of Stomatology, North China University of Science and Technology, Tangshan 063000, Hebei Province, China -

About author:Jia Wan-ping, Master candidate, Physician, Department of Orthodontics, School of Stomatology, North China University of Science and Technology, Tangshan 063000, Hebei Province, China -

Supported by:the National Natural Science Foundation of China, No. 81270965; the Major Project of Hebei Provincial Educational Department, No. ZD2015016

CLC Number:

Cite this article

Jia Wan-ping, Dong Wei, Peng Hong-feng, Xu Yan-li, Wang Hong-mei, Liang Li-shuo, Qi Meng-chun, Liang Yong-qiang. Preparation of magnesium-doped brushite by sintering method[J]. Chinese Journal of Tissue Engineering Research, doi: 10.3969/j.issn.2095-4344.0781.

share this article

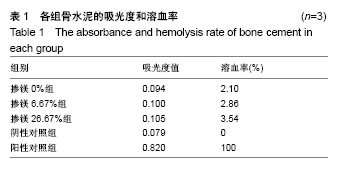

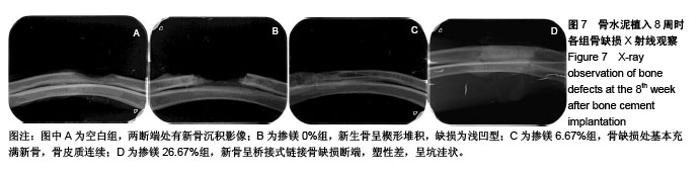

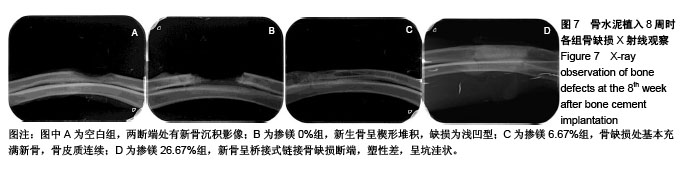

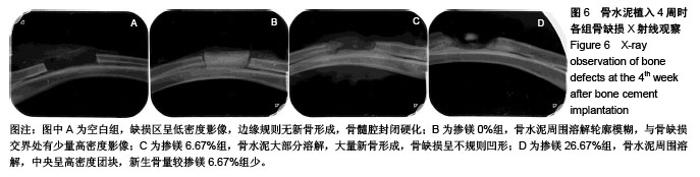

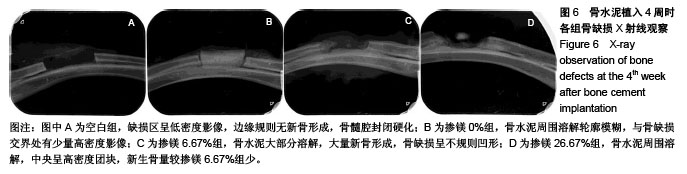

2.5 成骨效果分析 术后3 d家兔进食进水恢复,术区无感染。通过大体观察和骨X射线片分析各组缺损区的成骨效果。 大体观察:植入4周时,缺损区被结缔纤维组织包绕,剔除软组织观察骨水泥溶解及成骨情况,空白组断端规则,骨髓腔封闭;掺镁0%组骨水泥周围溶解呈虫蚀状,断端处有骨痂形成;掺镁6.67%组骨水泥大部分溶解,溶解的部分被新生骨代替,骨缺损呈凹形,掺镁26.67%组骨水泥溶解角掺镁6.67%组少,大量骨痂形成,断端有新骨形成。植入8周时,空白组纤维软组织充填缺损区,新生骨较少,缺损面积较大;掺镁0%组可见少量颗粒状骨水泥,缺损形成表面粗糙的连续骨痂,缺损呈浅凹形;掺镁6.67%组基本完成修复,骨连接表面连续光滑;26.67%组两管端被骨痂桥接,表面呈锯齿凹坑状。 X射线结果:植入4周时,空白组缺损区呈低密度影像,边缘规则无新骨形成,骨髓腔封闭硬化;掺镁0%组骨水泥周围溶解轮廓模糊,与骨缺损交界处有少量高密度影像;掺镁6.67%组骨水泥大部分溶解,大量新骨形成,骨缺损呈不规则凹形;掺镁26.67%组骨水泥周围溶解,中央呈高密度团块,新生骨量较掺镁6.67%组少(图6)。植入8周时,空白组两断端处有新骨沉积影像;掺镁0%组新生骨呈楔形堆积,缺损为浅凹型;掺镁6.67%组骨缺损处基本充满新骨,骨皮质连续;掺镁26.67%组新骨呈桥接式链接骨缺损断端,塑性差,呈坑洼状(图7)。 "

| [1] Gbureck U,Dembski S,Thull R,et al.Factors influencing calcium phosphate cement shelf-life. Biomaterials. 2005; 26(17):3691-3697.[2] Mirtchi AA,Lemaître J,Munting E.Calcium phosphate cements: study of the β-tricalcium phosphate- dicalcium phosphate- calcite cements.Biomaterials.1990;11(2):83-88.[3] Tamimi F,Kumarasami B,Doillon C,et al.Brushite–collagen composites for bone regeneration. Acta Biomaterialia. 2008; 4(5):1315-1321.[4] Flautre B,Lemaître J,Maynou C,et al.Influence of polymeric additives on the biological properties of brushite cements: An experimental study in rabbit.J Biomed Mater Res A. 2003; 66(2):214-223.[5] Lagazzo A,Barberis F,Carbone C,et al.Molecular level interactions in brushite-aminoacids composites.Mater Sci Eng C Mater Biol Appl.2017;70(Pt 1):721-727.[6] 王海霞,岳进.梯度掺锶羟基磷灰石骨水泥的体外细胞生物学性能[J].中国组织工程研究,2013, 17(47):8149-8154.[7] 员丽颖.透钙磷石涂层浸提液溶入不同浓度锶后联合应用的生物学评价[D].河北联合大学,2014.[8] 王买全,李运峰.微量元素锶与骨质疏松症[J].中国骨质疏松杂志, 2014,20(10):1258-1262.[9] 高麒,牛强,李永锋,等.掺锶仿生涂层用于促进种植体早期骨结合的初步研究[J].牙体牙髓牙周病学杂志, 2014,24(4):216-220.[10] Sopcak T,Medvecky L,Giretova M,et al.Effect of phase composition of calcium silicate phosphate component on properties of brushite based composite cements.Mater Charact.2016;117:17-29.[11] Pina S,Vieira SI,Torres PM,et al.In vitro performance assessment of new brushite-forming Zn-and ZnSr-substituted beta-TCP bone cements.J Biomed Mater Res B Appl Biomater.2010;94(2):414-420. [12] 顾雪梅,安燕,杨雪艳,等.含锶纳米羟基磷灰石的制备及性能研究[J].无机盐工业,2015,47(1):30-32.[13] Jallot E,Nedelec JM,Grimault AS,et al.STEM and EDXS characterisation of physico-chemical reactions at the periphery of sol-gel derived Zn-substituted hydroxyapatites during interactions with biological fluids.Colloids Surf B Biointerfaces.2005;42(3-4):205-210.[14] 周秋娟,梁永强,李淑静,等.掺锶透钙磷石骨水泥修复家兔牙槽骨缺损的研究[J].安徽医科大学学报,2017, 52(4):589-592.[15] 李昊妍.掺锶透钙磷石钛种植体体内骨整合的实验研究[D].华北理工大学,2015.[16] 李忻畅.掺锶透钙磷石涂层对骨质疏松大鼠种植支抗骨整合影响[D].华北理工大学,2016.[17] 刘巧巧.透钙磷石涂层掺锶对ME3T3-E1细胞的增殖、分化影响[D].河北联合大学,2014.[18] 闫玉婷,李忻畅,田景瑞,等.掺锶10%透钙磷石骨水泥修复兔下颌牙槽骨缺损的效果[J].郑州大学学报医学版, 2016,51(5): 614-617.[19] Kotsar A,Nieminen R,Isotalo T,et al.Biocompatibility of new drug-eluting biodegradable urethral stent materials. Urology. 2010;75(1):229-234.[20] GB/T16886.12-2005.医疗器械生物学评[S].[21] 赵勤富,郑力,王思玲.纳米多孔羟基磷灰石的制备方法及其在药物载体方面应用的研究进展[J].沈阳药科大学学报,2010, 27(12):1009-1013.[22] Apelt D,Theiss F,El-Warrak AO,et al.In vivo behavior of three different injectable hydraulic calcium phosphate cements. Biomaterials.2004;25(7):1439-1451.[23] Liang Y,Li H, Xu J,et al.Morphology, composition, and bioactivity of strontium-doped brushite coatings deposited on titanium implants via electrochemical deposition.Int J Mol Sci.2014;15(6):9952-9962.[24] 侯光辉.透钙磷石复合材料修复动物骨缺损的初步实验研究[D].中南大学,2010. [25] Barralet JE,Grover LM,Gbureck U.Ionic modification of calcium phosphate cement viscosity. Part II: hypodermic injection and strength improvement of brushite cement. Biomaterials.2004;25(11):2197-2203. [26] 孙俊芬,曹伟烨,马冰冰.掺镁羟基磷灰石的合成及对蛋白质吸附性能的影响[J].离子交换与吸附,2014,30(1):20-28. [27] 闫玉婷.掺锶透钙磷石骨水泥修复牙槽骨缺损的实验研究[D].华北理工大学,2016.[28] 杨迪诚,钟建,刘涛,等.透钙磷石骨水泥制备及其载药性能[J].中国组织工程研究,2015,19(3):427-433.[29] Engstrand J,Persson C,Engqvist H.The effect of composition on mechanical properties of brushite cements.J Mech Behav Biomed Mater.2014;29(1):81-90.[30] Kwon SH,Jun YK,Hong SH,et al.Synthesis and dissolution behavior of β-TCP and HA/β-TCP composite powders.J Eur Ceram Soc.2003;23(7):1039-1045.[31] Lin FH,Liao CJ,Chen KS,et al.Petal-like apatite formed on the surface of tricalcium phosphate ceramic after soaking in distilled water.Biomaterials.2001;22(22):2981-2992.[32] 王端诚,颜廷亭,黄明华,等.掺镁羟基磷灰石晶须的制备与研究[J].人工晶体学报,2014,43(3):648-651.[33] 李星逸,马野,袁世丹.多孔含镁羟基磷灰石的烧结行为及其组织结构[J].中国体视学与图像分析, 2015,20(4):392-399.[34] Bohner M,Gbureck U.Thermal reactions of brushite cements.J Biomed Mater Res B Appl Biomater. 2008;84(2): 375-385.[35] Gbureck U,Barralet JE,Spatz K,et al.Ionic modification of calcium phosphate cement viscosity. Part I: hypodermic injection and strength improvement of apatite cement. Biomaterials.2004;25(11):2187-2195.[36] Huang J,Ren Y, hang B,et al.Study on Biocompatility of Magnesium and Its Alloys.Rare Metal Mater Eng. 2007;36(6): 1102-1105.[37] Cabrejos-Azama J,Alkhraisat MH,Rueda C,et al.Magnesium substitution in brushite cements for enhanced bone tissue regeneration.Mater Sci Eng C Mater Biol Appl. 2014;43: 403-410.[38] Alkhraisat MH,Cabrejos-Azama J,Rodríguez CR,et al. Magnesium substitution in brushite cements. Mater Sci Eng C Mater Biol Appl.2013;33(1):475-481. |

| [1] | Zhang Tongtong, Wang Zhonghua, Wen Jie, Song Yuxin, Liu Lin. Application of three-dimensional printing model in surgical resection and reconstruction of cervical tumor [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(9): 1335-1339. |

| [2] | Zeng Yanhua, Hao Yanlei. In vitro culture and purification of Schwann cells: a systematic review [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(7): 1135-1141. |

| [3] | Xu Dongzi, Zhang Ting, Ouyang Zhaolian. The global competitive situation of cardiac tissue engineering based on patent analysis [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(5): 807-812. |

| [4] | Wu Zijian, Hu Zhaoduan, Xie Youqiong, Wang Feng, Li Jia, Li Bocun, Cai Guowei, Peng Rui. Three-dimensional printing technology and bone tissue engineering research: literature metrology and visual analysis of research hotspots [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 564-569. |

| [5] | Chang Wenliao, Zhao Jie, Sun Xiaoliang, Wang Kun, Wu Guofeng, Zhou Jian, Li Shuxiang, Sun Han. Material selection, theoretical design and biomimetic function of artificial periosteum [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 600-606. |

| [6] | Liu Fei, Cui Yutao, Liu He. Advantages and problems of local antibiotic delivery system in the treatment of osteomyelitis [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 614-620. |

| [7] | Li Xiaozhuang, Duan Hao, Wang Weizhou, Tang Zhihong, Wang Yanghao, He Fei. Application of bone tissue engineering materials in the treatment of bone defect diseases in vivo [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 626-631. |

| [8] | Zhang Zhenkun, Li Zhe, Li Ya, Wang Yingying, Wang Yaping, Zhou Xinkui, Ma Shanshan, Guan Fangxia. Application of alginate based hydrogels/dressings in wound healing: sustained, dynamic and sequential release [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 638-643. |

| [9] | Chen Jiana, Qiu Yanling, Nie Minhai, Liu Xuqian. Tissue engineering scaffolds in repairing oral and maxillofacial soft tissue defects [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 644-650. |

| [10] | Xing Hao, Zhang Yonghong, Wang Dong. Advantages and disadvantages of repairing large-segment bone defect [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(3): 426-430. |

| [11] | Chen Siqi, Xian Debin, Xu Rongsheng, Qin Zhongjie, Zhang Lei, Xia Delin. Effects of bone marrow mesenchymal stem cells and human umbilical vein endothelial cells combined with hydroxyapatite-tricalcium phosphate scaffolds on early angiogenesis in skull defect repair in rats [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(22): 3458-3465. |

| [12] | Wang Hao, Chen Mingxue, Li Junkang, Luo Xujiang, Peng Liqing, Li Huo, Huang Bo, Tian Guangzhao, Liu Shuyun, Sui Xiang, Huang Jingxiang, Guo Quanyi, Lu Xiaobo. Decellularized porcine skin matrix for tissue-engineered meniscus scaffold [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(22): 3473-3478. |

| [13] | Mo Jianling, He Shaoru, Feng Bowen, Jian Minqiao, Zhang Xiaohui, Liu Caisheng, Liang Yijing, Liu Yumei, Chen Liang, Zhou Haiyu, Liu Yanhui. Forming prevascularized cell sheets and the expression of angiogenesis-related factors [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(22): 3479-3486. |

| [14] | Liu Chang, Li Datong, Liu Yuan, Kong Lingbo, Guo Rui, Yang Lixue, Hao Dingjun, He Baorong. Poor efficacy after vertebral augmentation surgery of acute symptomatic thoracolumbar osteoporotic compression fracture: relationship with bone cement, bone mineral density, and adjacent fractures [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(22): 3510-3516. |

| [15] | Liu Liyong, Zhou Lei. Research and development status and development trend of hydrogel in tissue engineering based on patent information [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(22): 3527-3533. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||