Chinese Journal of Tissue Engineering Research ›› 2018, Vol. 22 ›› Issue (2): 274-280.doi: 10.3969/j.issn.2095-4344.0018

Previous Articles Next Articles

Numerical simulation analysis of the internal flow field of a 3D biological printhead based on FLUENT

- 1College of Mechanical Engineering, Yangzhou University, Yangzhou 225127, Jiangsu Province, China; 2College of Animal Science and Technology, Yangzhou University, Yangzhou 225009, Jiangsu Province, China; 3Medical College of Yangzhou University, Yangzhou 225001, Jiangsu Province, China

-

Received:2017-12-05Online:2018-01-18Published:2018-01-18 -

Contact:Zhou Ji-ping, Professor, Doctoral supervisor, College of Mechanical Engineering, Yangzhou University, Yangzhou 225127, Jiangsu Province, China -

About author:Liu Dong-fang, Studying for master’s degree, College of Mechanical Engineering, Yangzhou University, Yangzhou 225127, Jiangsu Province, China; College of Animal Science and Technology, Yangzhou University, Yangzhou 225009, Jiangsu Province, China -

Supported by:the National Natural Science Foundation of China, No. 81770018

CLC Number:

Cite this article

Liu Dong-fang, Zhou Ji-ping, Shi Hong-can, Xu Xiao-dong, Jiang Ya-ni, Zhang Qi.

share this article

Add to citation manager EndNote|Reference Manager|ProCite|BibTeX|RefWorks

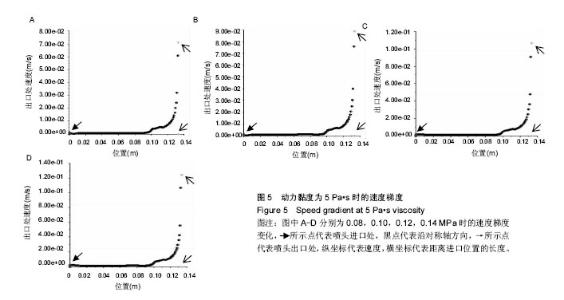

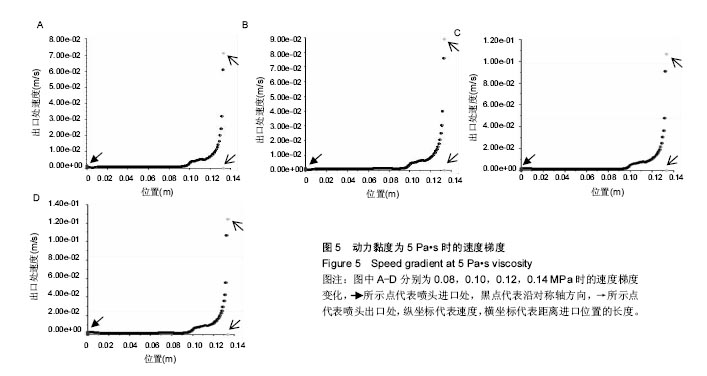

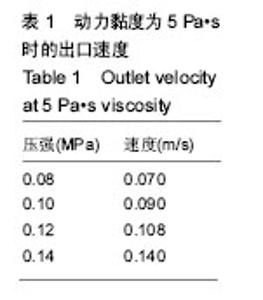

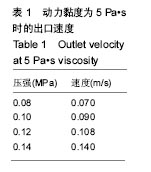

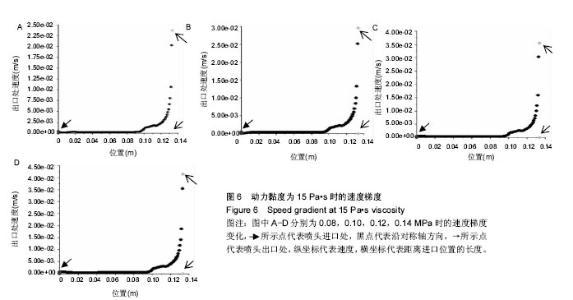

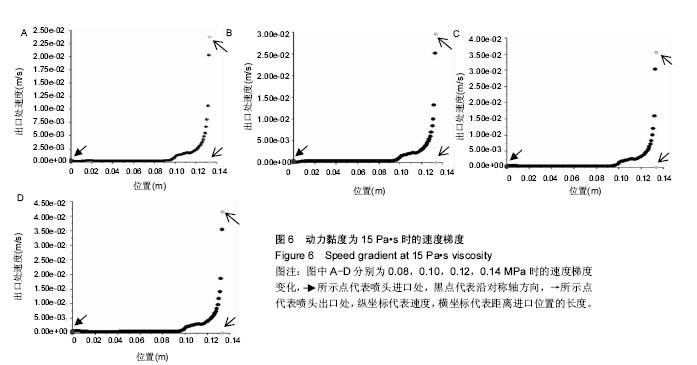

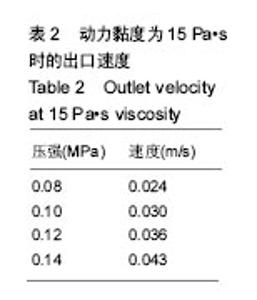

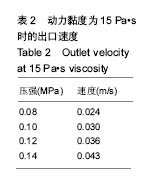

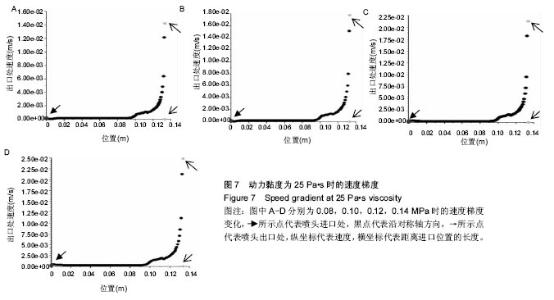

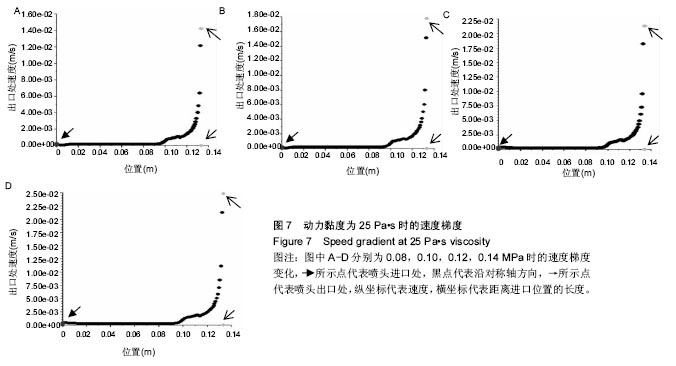

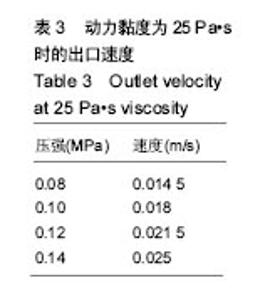

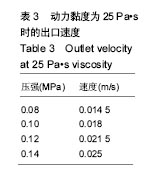

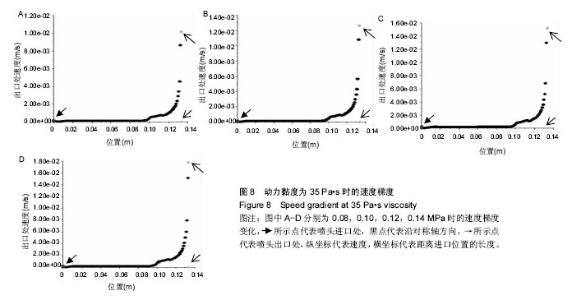

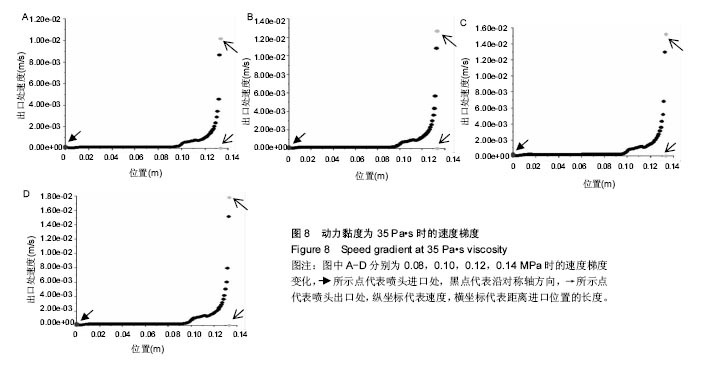

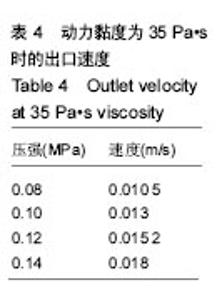

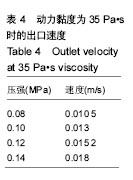

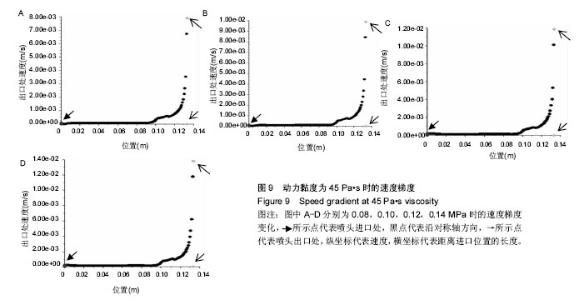

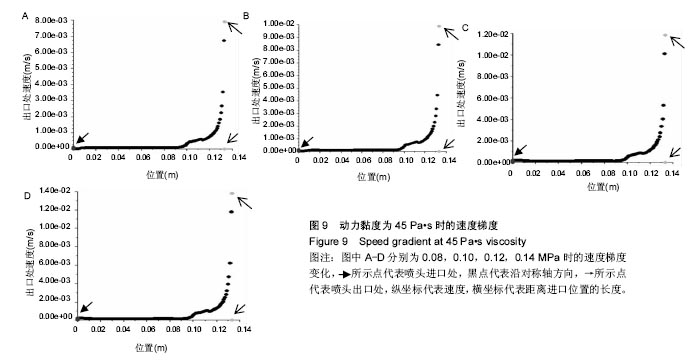

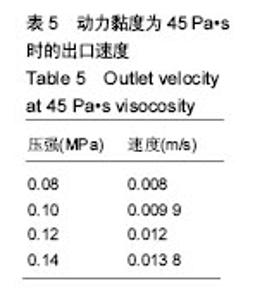

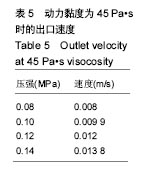

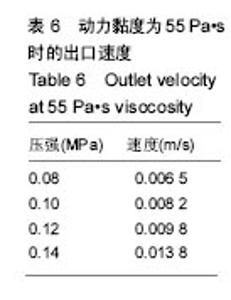

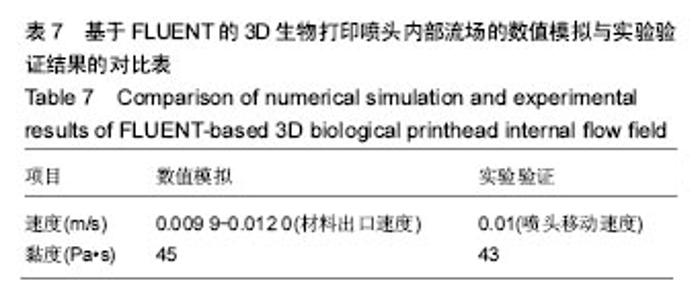

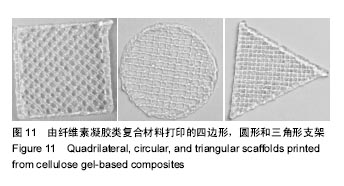

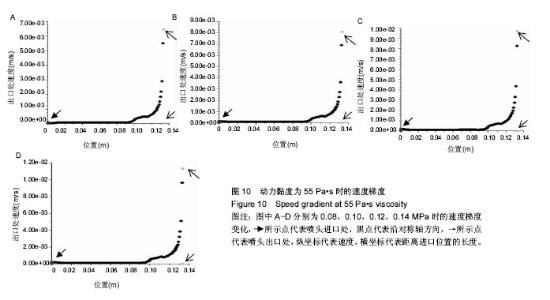

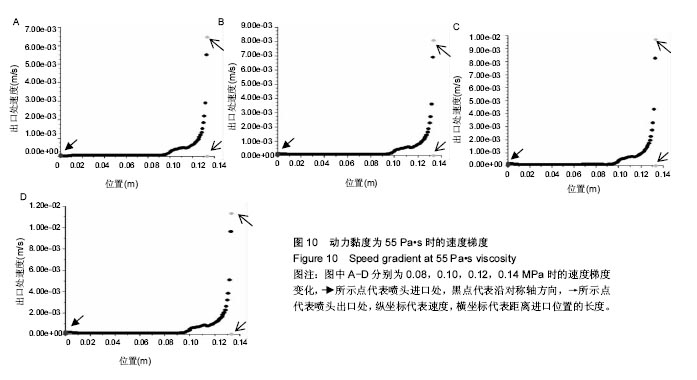

当动力黏度为55 Pa•s时,其速度梯度变化如图10所示,速度在沿对称轴方向变化情况同上所述,其中出口速度变化如表6所示,与表1-4数据相比,表6数值较小,其相邻压强的出口速度差值约为0.001 7-0.004 0之间,与表1-4数据相比,表6数据变化范围较大,又出口速度最大值为0.013 8 m/s,最小值为0.006 5,故出口速度受压强变化影响较大。 由于喷头内部材料的流出速度还与喷头的行走速度有关,则设定时间t内从喷头内挤出的水凝胶纤维素复合材料为V喷头,则 其中,d1为图2所示喷头出口处直径,υ1为喷头出口速度,d2为图10所示所打印支架每条丝的直径,υ2为喷头移动速度。忽略支架凝固时的密度变化,则υ1≈υ2,又由于在实际操作中,打印速度保持在0.01 m/s的时候,打印不容易断丝[15-18],故当动力黏度为5,15,25 Pa•s的时候,由于其出口速度过快会导致打印过程中出现过堆积的现象[19-23],如图1所示。又气体在注入喷头的时候,会产生一定的压缩现象[24-25],使实际压强大于显示的压强[26-27],故选择出口速度受压强影响变化较为缓慢的情况[28-29],当动力黏度为35和55 Pa•s的时候速度随压强的变化不呈平缓状态,则不合适舍去[30-33],动力黏度为45 Pa•s的时候,在压强为0.10-0.12 MPa的时候,出口速度随压强变化较为平缓,则其是作为针对纤维素凝胶类复合材料进行3D打印避免过堆积现象的最佳打印参数[34-35]。"

| [1]Langer R, Vacanti JP. Tissue engineering. Science. 1993; 260(5110):920-926.[2]李坚. 3D打印水凝胶支架的摩擦行为研究[D].湖北工业大学, 2016.[3]Harris IR, Harmoon AM, Brown LJ, et al. Tissue-engineering scaffolds containing self-assembled-peptide hydrogel: US, 8039258.2011-10-18.[4]Bonassar LJ, Vacanti CA. Tissue engineering: the first decade and beyond. J Cell Biochem Suppl. 1998;30-31: 297-303.[5]Gauvin R, Chen YC, Lee JW, et al. Microfabrication of complex porous tissue engineering scaffolds using 3D projection stereolithography. Biomaterials. 2012;33(15): 3824-3834. [6]Khalil S, Nam J, Sun W. Multi-nozzle deposition for construction of 3D biopolymer tissue scaffolds. Rapid Prototyp J. 2005;11(1):9-17.[7]胡杨,余小月,但卫华,等. 胶原基水凝胶的制备、结构性能表征及其在生物医学中的应用[J].功能材料,2017,48(1):1038-1046. [8]刘许,宋阳.用于3D打印的生物相容性高分子材料[J].合成树脂及塑料,2015,32(4):96-99,102. [9]谷龙.面向皮肤组织工程的水凝胶与细胞打印研究[D].浙江大学, 2017.[10]王福军.计算流体动力学分析:CFD软件原理与应用[M].北京:清华大学出版社,2001.[11]赵帝.仿生人工骨3D打印流场仿真分析及试件力学性能研究[D].吉林大学,2015.[12]贾永臻,廖敦明,陈涛,等.基于Fluent的3D打印ABS熔体热流模拟分析[J].塑料,2017,46(1):61-64. [13]邓平平.骨组织工程支架内微流体及其变形的数值仿真分析[D].秦皇岛:燕山大学,2011.[14]赵静一,陈红波.基于FLUENT的人工骨支架内两相流数值分析[C]//中国力学学会.庆祝中国力学学会成立50周年暨中国力学学会学术大会’2007论文摘要集(下).中国力学学会,2007:1.[15]董世磊. 三维生物打印构建电活性水凝胶组织工程支架的研究[D].北京:北京印刷学院,2017.[16]夏冰.生物凝胶结构三维可打印性研究[D].南京:南京师范大学, 2016.[17]姜杰.基于三维打印的组织工程支架成型工艺及其性能研究[D].南京:南京师范大学,2016.[18]彭波.双网络水凝胶支架的三维打印制备工艺及性能研究[D].广州:华南理工大学,2016.[19]成利波.强韧水凝胶的3D打印工艺及机理研究[D].杭州:浙江大学,2017.[20]马哲一.骨组织工程支架内微流体流动状态的数值仿真及分析[D].秦皇岛:燕山大学,2009.[21]张烈烈.基于光学相干层析的三维生物打印水凝胶优化控制研究[D].杭州:杭州电子科技大学,2016.[22]毛伟,连芩,李涤尘,等.立体空心血管网水凝胶支架的3D打印工艺研究[J].机械工程学报,2017,53(9):180-186. [23]宋建康.纤维素纳米纤维的制备及其在组织工程支架中的应用[D].广州:华南理工大学,2012.[24]张旭婧. 3D同轴打印组织工程骨支架成型工艺与实验研究[D].乌鲁木齐:新疆大学,2017.[25]于海悦,麻丹丹,吴补领.3D打印明胶海藻酸钠凝胶支架对人牙髓细胞的黏附增殖作用[J].南方医科大学学报,2017,37(5): 668-672. [26]周琦琪. 3D打印组织工程骨支架的骨改建机制研究[D].乌鲁木齐:新疆医科大学,2017.[27]储成艳,朱亮,王苏平,等.胶原凝胶构建神经组织工程支架的实验研究[J].中国修复重建外科杂志,2017,31(3):363-368. [28]方幸幸.仿生明胶甲基丙烯酰胺水凝胶支架的骨组织工程研究[D].广州:南方医科大学,2016.[29]张仁坤. 3-D打印支架载NeuroD1修饰的神经干细胞修复脊髓损伤的实验研究[D].石家庄:河北医科大学,2016.[30]薛延香. PLGA、壳聚糖、纳米银混合物的制备及生物学特性初步研究[D].广州:南方医科大学,2015.[31]武成聪,王芳,荣树,等.3D打印应用在骨组织工程研究中的特点与进展[J].中国组织工程研究,2017,21(15):2418-2423.[32]胡颖.凝胶流道网络3D打印制造研究[D].杭州:浙江大学,2015.[33]涂沛. OCT技术用于三维打印水凝胶支架在线评价研究[D].杭州:杭州电子科技大学,2015.[34]许杜亮,莫秀梅.3D打印技术制备明胶纳米微球基复合凝胶支架[J].东华大学学报(自然科学版),2014,40(6):718-722,757. [35]卢璐,吉鸿飞,郭各朴,等.超声增强藻酸钙凝胶支架材料孔隙率的研究[J].物理学报,2015,64(2):264-271. [36]郑振粮. 3D打印按需滴化微喷射关键技术[D].哈尔滨:哈尔滨工业大学,2015.[37]滕文琪.高韧度水凝胶人工角膜支架的制备及其性能研究[D].杭州:浙江大学,2014.[38]刘金浩.水溶性双光子聚合引发剂的制备及3D水凝胶微加工[D].天津:天津大学,2014.[39]胡婷婷.纤维素纳米纤维三维组织工程支架的构建及其体外降解性研究[D].广州:华南理工大学,2013.[40]吴任东,杨辉,张磊,等.组织工程支架快速成形技术研究现状[J].机械工程学报,2011,47(5):170-176. |

| [1] | Zhang Tongtong, Wang Zhonghua, Wen Jie, Song Yuxin, Liu Lin. Application of three-dimensional printing model in surgical resection and reconstruction of cervical tumor [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(9): 1335-1339. |

| [2] | Zeng Yanhua, Hao Yanlei. In vitro culture and purification of Schwann cells: a systematic review [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(7): 1135-1141. |

| [3] | Xu Dongzi, Zhang Ting, Ouyang Zhaolian. The global competitive situation of cardiac tissue engineering based on patent analysis [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(5): 807-812. |

| [4] | Wu Zijian, Hu Zhaoduan, Xie Youqiong, Wang Feng, Li Jia, Li Bocun, Cai Guowei, Peng Rui. Three-dimensional printing technology and bone tissue engineering research: literature metrology and visual analysis of research hotspots [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 564-569. |

| [5] | Chang Wenliao, Zhao Jie, Sun Xiaoliang, Wang Kun, Wu Guofeng, Zhou Jian, Li Shuxiang, Sun Han. Material selection, theoretical design and biomimetic function of artificial periosteum [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 600-606. |

| [6] | Liu Fei, Cui Yutao, Liu He. Advantages and problems of local antibiotic delivery system in the treatment of osteomyelitis [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 614-620. |

| [7] | Li Xiaozhuang, Duan Hao, Wang Weizhou, Tang Zhihong, Wang Yanghao, He Fei. Application of bone tissue engineering materials in the treatment of bone defect diseases in vivo [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 626-631. |

| [8] | Zhang Zhenkun, Li Zhe, Li Ya, Wang Yingying, Wang Yaping, Zhou Xinkui, Ma Shanshan, Guan Fangxia. Application of alginate based hydrogels/dressings in wound healing: sustained, dynamic and sequential release [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 638-643. |

| [9] | Chen Jiana, Qiu Yanling, Nie Minhai, Liu Xuqian. Tissue engineering scaffolds in repairing oral and maxillofacial soft tissue defects [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(4): 644-650. |

| [10] | Xing Hao, Zhang Yonghong, Wang Dong. Advantages and disadvantages of repairing large-segment bone defect [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(3): 426-430. |

| [11] | Chen Siqi, Xian Debin, Xu Rongsheng, Qin Zhongjie, Zhang Lei, Xia Delin. Effects of bone marrow mesenchymal stem cells and human umbilical vein endothelial cells combined with hydroxyapatite-tricalcium phosphate scaffolds on early angiogenesis in skull defect repair in rats [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(22): 3458-3465. |

| [12] | Wang Hao, Chen Mingxue, Li Junkang, Luo Xujiang, Peng Liqing, Li Huo, Huang Bo, Tian Guangzhao, Liu Shuyun, Sui Xiang, Huang Jingxiang, Guo Quanyi, Lu Xiaobo. Decellularized porcine skin matrix for tissue-engineered meniscus scaffold [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(22): 3473-3478. |

| [13] | Mo Jianling, He Shaoru, Feng Bowen, Jian Minqiao, Zhang Xiaohui, Liu Caisheng, Liang Yijing, Liu Yumei, Chen Liang, Zhou Haiyu, Liu Yanhui. Forming prevascularized cell sheets and the expression of angiogenesis-related factors [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(22): 3479-3486. |

| [14] | Liu Chang, Li Datong, Liu Yuan, Kong Lingbo, Guo Rui, Yang Lixue, Hao Dingjun, He Baorong. Poor efficacy after vertebral augmentation surgery of acute symptomatic thoracolumbar osteoporotic compression fracture: relationship with bone cement, bone mineral density, and adjacent fractures [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(22): 3510-3516. |

| [15] | Liu Liyong, Zhou Lei. Research and development status and development trend of hydrogel in tissue engineering based on patent information [J]. Chinese Journal of Tissue Engineering Research, 2021, 25(22): 3527-3533. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||